Matsui America, Inc.

5825 Turnberry Dr.

Hanover Park, IL 60133 US

847-290-9680

info@matsuiamerica.com

matsuiamerica.com

IS THIS YOUR COMPANY?

As Seen On Plastics Technology

Matsui America, Inc. Supplies the Following Products

- Blenders (non-intensive)

- Chillers

- Conveying Equipment (pneumatic and Mechanical)

- Conveyors (parts-handling)

- Cooling Towers

- Dryers for Resins

- Dust Removal Equipment

- Feeders

- General Purpose Robots and EOAT

- Granulators

- Heat-recovery Systems

- Hopper Loaders

- Hoppers, Bins, Tanks

- Hot-water or Oil-circulating Temperature Controllers

- Metal Detectors, Separators

- Metering, Proportioning Equipment

- Part or Sprue Removal Robots and EOAT

- Parts/Runner Separators

- Semi-bulk Containers

- Shredders, Guillotines

- Silos

- Tumblers

Editorial, News, and Products

-

Scaling New Heights With Vertical Integration

Eden Manufacturing was founded on a vision of vertical integration, adding advanced injection molding capabilities to a base of precision moldmaking and more recently bringing Swiss-type machining capabilities in-house.

-

Pelletizing System for Engineered Resins and Recycled Materials for Optical Molding

NPE2024: Matsui America is introducing the Raptor 22 pelletizing system.

-

Back in the Family Business

In its 45th year, Precision Molded Plastics has carved out a technology and market niche, growing not just when opportunities arise but when they make sense, after its leader changed careers to keep the family business from changing hands.

-

Matsui America PTXPO Spotlight

Matsui America discusses the upcoming Plastics Technology Expo (PTXPO) March 28-30

-

Water Quality Management System Filters, Softens Process Water

Matsui’s 3Zone Preclear system targets contaminants and water-hardening minerals to decrease molding cycle times, reduce chiller energy usage and extend mold life.

-

Niigata Fills New Regional Sales Manager Role

Gregory Lewis will occupy the new position created after the injection molding machine supplier began direct sales in the U.S. in 2019.

-

Data Driven, Employee Owned

Approaching its seventh decade in business, PTA Plastics has shifted its location and remade its customer base since its founding in 1953, but many things have not changed in the intervening years, including an emphasis on people and leading-edge technologies.

-

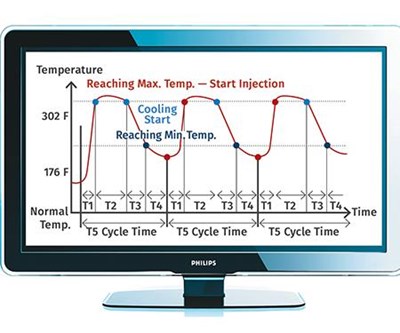

Hot/Cold Injection Molding: Which Approach Is Best for You?

The hot-and-cold molding process gives molders a new tool to achieve top-quality esthetics or to fill challenging thin-wall parts. There are a number of options in heating methods, and this article discusses the ins and outs of each.

-

AUXILIARIES AT NPE: More Control, Flexibility, And Efficiency

These are key trends in the many kinds of auxiliary equipment displayed at this month’s show. You’ll also see equipment designed to be virtually ‘foolproof.’

-

Teel Plastics: Where Science, Tech, Quality and Innovation Meet

This family-owned custom profile and tubing business controls its own destiny by controlling, well, everything.

-

Savvy Processors Reveal Best Practices on Drying

The processors speak: Here’s how some smart molders and extruders tackle the vexing problem of resin drying.

-

Auxiliaries at NPE: News in Materials Handling, Cooling, Granulating, Welding, Testing, Decorating

Auxiliary equipment takes in a broad range of functions, from materials preparation to post-mold finishing.

-

NPE News Wrap-up: Resin Dryers

At least 16 companies introduced new dryers at the big show in Chicago. The new models span a range of drying technologies, but most sport features that save space and cost and make the dryers simpler and more reliable.

-

Molder’s Message to Foreign Competitors: ‘Bring It On!’

An inspired combination of automation, ISO certification, use of certified resins, and strict adherence to a rigorous set of time-honed manufacturing standards are among the chief factors giving the Rodon Group, a 54-year-old custom molding operation in Hatfield, Pa., the confidence to boast that it can beat the pants off of Chinese part pricing, and Mexican pricing, too.And it’s not an idle boast.

-

Materials Handling: New Equipment Emphasizes Efficiency & Value

Visitors to the recent NPE 2009 show in Chicago were looking for materials handling equipment that could do more than dry, blend, or convey resins. It had to do those things while saving energy, providing faster and easier maintenance, speeding product changeovers, reducing labor cost, minimizing waste, and providing better value for money. The new products cited below addressed those needs and more.

-

HOW TO COMPARE DRYERS? A Complex Challenge With No Simple Answers

Is one type of resin dryer faster or more energy-efficient than another? That question prompts competing claims from suppliers—but very little concrete data. When one vendor performed controlled tests to get some answers, its results, published here for the first time, prompted further debate about the difficulties of making valid comparisons and the many complex issues involved in dryer selection.

-

NPE 2006 News Wrap-Up: Materials Handling: A Host of Refinements and Updates

NPE 2006 held no revolutionary changes in dryers, blenders, feeders, loaders, or conveying controls, but widely adopted improvements make the newest models easier to use and maintain—and easier on the budget, too.

-

What to See at NPE 2006: Heating and Cooling

Most of the news at the show is in fluid-circulating mold-temperature-control systems.

-

What to See at NPE 2006: Materials and Parts Handling

Dryers, feeders, blenders, loaders, metal detectors, level sensors, mechanical and pneumatic conveyors, silos, bins, pumps, filters, valves, box fillers, bag dumpers, and materials-handling control systems constitute one of the biggest categories of products on display at NPE.

-

Resin Dryers: Which Type Is Right for You?

Processors today face bewildering choices of at least five basic types of dryers, whose capabilities are subject to conflicting claims from equipment suppliers. For the buyer, the most basic questions are: How much drying is needed for the job and which dryer types are up to the task?

-

New Granulators Galore at NPE

Processors with scrap to grind must have noticed the prominence of screenless granulators with distinctive hooked “S-rotor” blades at the NPE show in Chicago.

-

NPE News Wrap-up - Water & Oil Temperature Control

If you’re the sort of manager that can’t resist checking up on your plant after you go home for the night, now you can click on your web browser and read out mold temperatures right there on your PC.