Barrier Blow Molding

Blow Molders Save Big On Compressed Air

Molders of PET containers are paying special attention these days to the large amounts of compressed air used in their blow molding operations and the huge energy cost associated with generating it.

Read MoreBranched PVDF Gains Melt Strength For Film, Blow Molding, Thermoforming

Chain branching opens up lots of new processing opportunities for these fluoropolymers.

Read MoreWhat's New at the Show in BLOW MOLDING

There will be a strong emphasis on energy savings in blow molding machinery at K 2007.

Read MoreIs Clear Handleware Ready for Prime Time?

Clear handled bottles got a kick start earlier this year when nationally recognized Simply Orange Juice Co., Apopka, Fla., an affiliate of the Minute Maid division of The Coca-Cola Co., decided to bottle its orange juice in extrusion blow molded 89-oz copolyester containers.

Read MorePET Container Stress Cracking: Myth Versus Science

Since the introduction of the first 2-liter, one-piece PET bottle by Continental Can Co. in Fall River, Mass., in 1978, the PET container’s nemesis has been stress cracking.

Read MoreNew Barrier Options Debut at SPE ANTEC

Innovative barrier technologies to boost the shelf-life of PET bottles were introduced at the May SPE ANTEC 2007 conference in Cincinnati.

Read MoreChemical Purging: When and How to Do It Right

Extrusion blow molders are sometimes skeptical of chemical purging compounds (CPCs), and they have a point.

Read MoreGlobal Competition - High Shipping Costs Give U.S. Blow Molders an Edge

When it comes to foreign competition, blow molders feel relatively invulnerable in their biggest market–bottles.

Read MoreNPE 2006 News Wrap-Up: Blow Molding

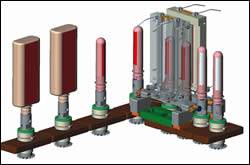

Among new blow molding developments at the show was an innovative coextrusion system for the growing small-engine fuel tank market.

Read MoreWhat to See at NPE 2006: Blow Molding

Show-goers will see a range of new blow molding equipment that offers higher speeds, more cavitation, and faster changeovers.

Read More