Compounding

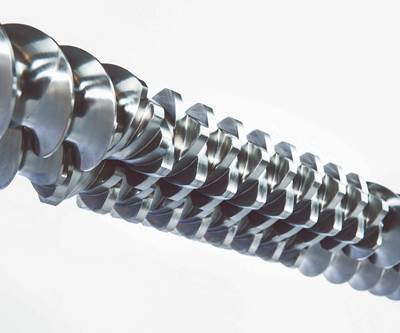

Why It's Crucial to Manage Melt-Temperature in a Twin-Screw Compounding Extruder

Managing and controlling melt temperature and degradation in a corotating compounding twin is critical to achieve process optimization. For compounders, it also greatly influences the ability of their molding and extrusion customers to make high-quality parts. Here are the results of research that illustrate this.

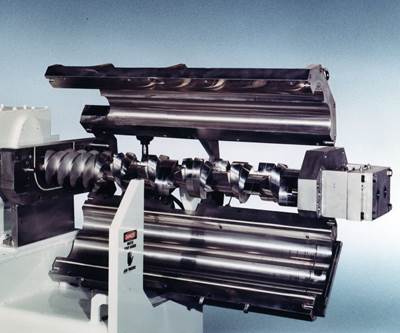

Read MoreCompounding: Continuous Processor Features Double Clamshell Barrel Design

Provides easy cleaning and inspection.

Read MoreMixing: Skid-Mounted Powder Induction & Mixing System

Rotor/stator generates a powerful vacuum without external pumps.

Read MoreMixing: Triple-Shaft Mixer Can Pivot

Machine can be raised from a vessel, rotate 90˚ and lowered into another vessel.

Read MoreStart-Up Compounder Seeks Niche in Short Orders, Quick Turns

Peak sets its sights on high-performance industrial and medical markets.

Read MoreCompounding: More Digital Solutions Come to Compounding

New GUI, ‘smart machine’ features, user friendly app highlight Coperion’s display at K 2019.

Read MoreCompounding: Revamped Line of Compounding Twins

Third-generation iMAXX twins are easier to clean and maintain, and are more energy efficient to boot.

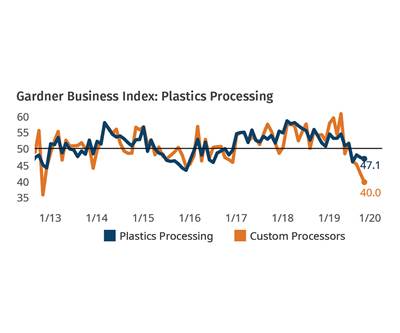

Read MoreIndex Dips on Weak Exports, Employment

October’s number drops from September, despite expansion in new orders.

Read MoreStrand Pelletizing: Follow These Steps to Determine Your Water Bath Length

Use heat-transfer equations as a shortcut to get you in the ballpark of how long your pelletizing water bath should be.

Read MoreCompounding: Quick-Color-Change Lab Twin

Throughout the exhibit, KraussMaffei ran nine different liquid colors, changing at the push of a button, to demonstrate time- and process-saving technology.

Read More