dies

Conformal Cooling Product Lines for Injection Molding and Blow Molding

Conformal cooling is a design approach for improving mold and die productivity that can save 10-50 percent or more on cycle time, in addition to quality benefits and improved tooling durability.

Read MoreRedesigned Multi-Layer Die for Precise Tubing

New Guill die can produce tubing from 1/1-6 in. OD for a range of applications.

Read MoreNovel ‘Stack Die’ Debuts at NPE2018

Modular blown film die can be expanded to accommodate up to 11 layers.

Read MoreMicro-Welding Solutions Offer Affordability and Variety

Gesswein Company presents new micro-welding solutions for mold and die repair.

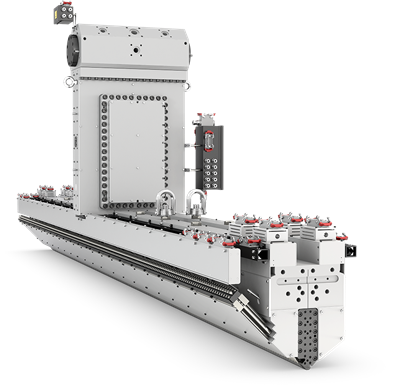

Read MoreFlexible, Expandable Blown Film Die

Modular design permits processors to run from 5 to 17 layers.

Read MoreFully Automated Mold-Change Is Here

An integrated solution using Stäubli's technology in a smart-factory setting shows how Single Minute Exchange of Die can work.

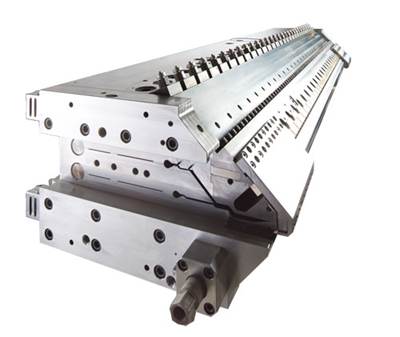

Read MoreEdge-Bead Reduction Die for Coatings, Largest-Ever 'Nano' Feedblock

Edge-bead reduction (EBR) die allows frequent web width and formulation changes, while nanolayer feedblock produces stretch films with enhanced performance.

Read MoreReifenhauser Buys Flat Die Maker EDS

Acquisition said to 'perfectly complement' Reifenhauser's existing expertise in die production.

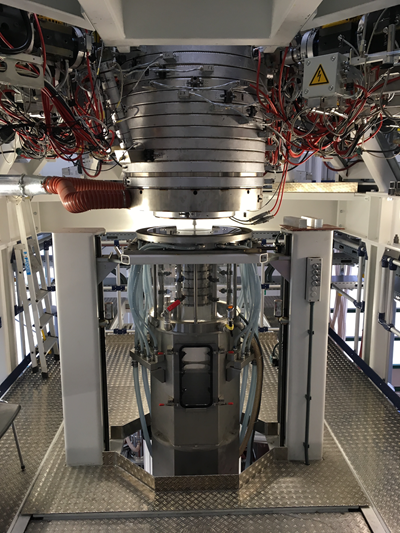

Read MoreGuill Opens Rheology Lab

Reportedly the only maker of round extrusion dies to have such a facility.

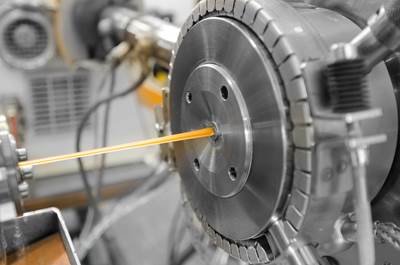

Read MoreExtrusion: Pilot Film Line And Flexible Die

Die can be used for lab work and for medical-tubing production.

Read More