dies

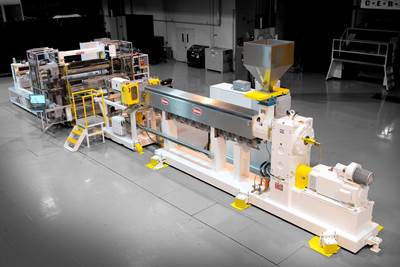

What You Need to Know to Get into Coextrusion

Key considerations range from determining the right extruder sizes to tooling, matching material viscosities, and lots more. Take a look.

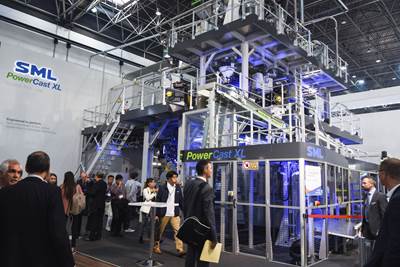

Read MoreExtrusion: High-Output Stretch Film Line

New ‘hands-free’ die control is said to permit fast and easy product changes.

Read MoreThermoforming: Flexible Steel-Rule Die Former

A single machine be used on a wide range of molds without the need for major mold modifications

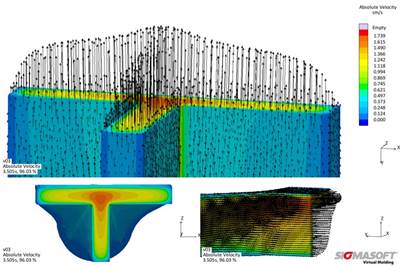

Read MoreExtrusion: Simulation Software Permits Die Optimization

Long-established supplier of mold and hot runner simulation software adds extrusion to its mix.

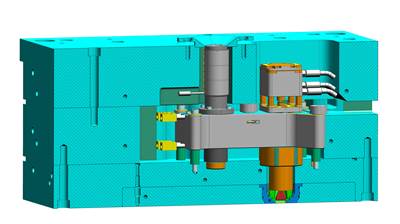

Read MoreTooling: New Flat Die Nozzle and Cloud-Powered Mold Monitoring

Haidlmair Group will launch two new companies and two new products at K 2019, including a new iteration of its flat die unit (FDU) and a mold monitoring technology.

Read MoreK 2019 Preview: Green's the Theme in Extrusion & Compounding

Themes of sustainability and the Circular Economy will be visible at the booths of many suppliers of extrusion and compounding equipment—film, in particular.

Read MoreDie Upgrade Improves Tolerances, Speeds Start-Ups for Shrink-Sleeve Processor

Switch to new Nordson die improved tolerances by 30%.

Read MoreGiving the ‘Royal’ Treatment in PET Packaging

In the U.S. for just seven years, Royal Interpack is emerging as a growing, innovative, customer-centric supplier of food packaging.

Read MoreRunipsys North America Opens New Sales and Service Center in Ontario

The France-based hot runner manufacturer has partnered with a tool and die maker in Windsor to establish a new sales and service center.

Read MorePart Two: Determining Viscosity Data Using a Slit Die Viscometer

Using a slit-die viscometer connected to a lab extruder can generate accurate data on melt viscosity at various shear rates and different temperatures—a useful QC tool in processing.

Read More