All Electric & Hybrid Machines

Gear Molding: Where It's Headed

Plastic gears are growing larger, more precise, more complex in geometry, and more powerful. High-performance resins and long-fiber compounds are aiding this evolution.

Read MoreNew Association for IML, IMD

Last month saw the official start-up of the In-Mold Decorating Association (IMDA), an association of molders, printers, materials suppliers, and equipment manufacturers involved in in-mold labeling and decorating (IML and IMD) for any plastics process.

Read MoreMold Analysis Gets Faster, Easier, Smarter

On Dec. 28, Moldflow Corp. began shipping a major new release of its flagship injection mold simulation software, Moldflow Plastics Insight 6.0.

Read MoreSPE Automotive Awards Highlight Materials and Processing Advances

What’s new in plastics on cars?

Read MoreEasy Cures for Common Complaints About Hot-Oil Units

Molders of high-temperature materials frequently ask these six questions about hot-oil temperature-control units (TCUs):Is smoke dangerous?Why is the pump discharge pressure bouncing all over?Why has the oil degraded and is it damaging the pump seals?Why can’t I get the mold hot enough without running the temperature above the flashpoint?Does it mean I’m running the oil too hot if I am getting carbon on the Y-strainer?If the oil has turned color, should it be replaced?There are straightforward answers and solutions to all of the above.

Read MoreHeadlines for the Next 50 Years

Ever wonder what it would be like to get tomorrow’s newspaper today? After reviewing the most important technical developments of the past 50 years in our October issue, we asked industry experts to help us imagine the biggest headlines in plastics from now to 2055. What we got was a mixture of predictions of what will happen and a wish list of what should happen.

Read MoreHybrid Prototyping Process Combines Casting and Machining

A new rapid-prototyping technique combines casting with CNC milling in a novel way to create prototype parts fas ter than conventional rapid prototyping approaches—and it all happens in one machine.

Read More50 Ideas That Changed Plastics

Very few readers of this issue can remember, or even imagine, what it was like when an injection molding machine did not have a screw, but only a smooth-bore plunger.

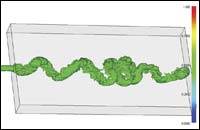

Read MoreWater Injection Molding: It's All Coming Together

Commercial applications in hollow-part molding with water—or water and gas—are starting to accelerate. They are driven by recent enhancements of process technology, equipment, and materials.

Read MoreChina Is Ready for Value-Added Molding

A number of U.S. injection molders are establishing Chinese joint ventures and satellite molding plants to take advantage of the huge market opportunities there and to defend against the perceived threat of low-cost competition.

Read More