Feeding & Blending

Finding Efficiencies in How Components Work Together

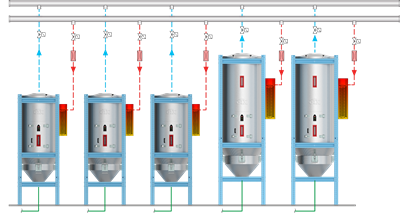

Auxiliary systems are vital to the proper functioning of a plastic processing line, and they can be a source of major cost and efficiency improvements.

Read MoreHigh-Performance, Cost-Effective Volumetric Feeder

New unit can handle a wide range of materials in various forms.

Read MorePiovanGroup Rebrands, with Mostly Minor Name Changes

For the most part, subsidiary company names will remain, with slight modifications meant to enhance the Group’s identity.

Read MoreCut Loading Time Through Direct Charge Blending

Direct charge blender loading, a vacuum-powered automation process, can dramatically improve loading time and reduce material costs. In this article, we address ten common questions to help you determine if the systems are right for your facility.

WatchHow to Effectively Reduce Costs with Smart Auxiliaries Technology

As drying, blending and conveying technologies grow more sophisticated, they offer processors great opportunities to reduce cost through better energy efficiency, smaller equipment footprints, reduced scrap and quicker changeovers. Increased throughput and better utilization of primary processing equipment and manpower are the results.

WatchHillenbrand Completes Schenck Acquisition

New business will join forces with Coperion/Coperion K-Tron, Herbold and others in Hillenbrand’s Advanced Process Solutions group.

Read MoreFeeder Handles Poor Flowing, Sticky Powders

Unit combines mechanical design of Kubota gravimetric feeders with Brabender Technologie GmbH’s load cell and motor technology.

Read MoreDual-Arch Bulk Bag Conditioner

Arched doorway masts increase overhead clearance to facilitate insertion and removal of palletized bulk bags using a forklift.

Read MoreFive Quick Steps Toward Better Blending

Rising costs of resins and additives, along with higher demands for quality and use of regrind, place a premium on proficient blending. Here are some steps to get you there.

Read MoreCaptive Molder Beefs Up Auxiliaries to Boost Quality, Consistency

SeeScan adds conveying, drying, feeding and chilling technologies to improve quality — and enhance employee safety — in production of its underground/underwater inspection systems.

Watch