Hot Runners

From NPE 2000: What's Hot in Hot Runners

Closer cavity spacing, in-press serviceability, improved valve gates, smarter controls, quick-ship standard manifolds, and Internet e-commerce were leading themes in hot runners at the big show in Chicago.Hot-runner components were one of the largest categories of injection molding products exhibited at the triennial NPE show in June.

Read MoreNPE Newsfinder: Control and Monitoring

Visitors to NPE can get a taste of how the Internet will serve as a gateway connecting processors to their process or linking customers to their orders.

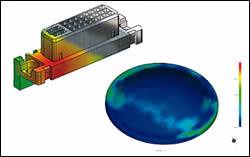

Read MoreThe New Dimension in Mold Simulation

Keep an eye on the increasing prominence of so-called “3D” mold analysis. Two vendors of simulation software from Europe and Asia think it’s the best solution for a big proportion of injection molded parts. Established U.S. suppliers aren’t so sure. In any case, the capabilities of both 3D and standard 2.5D simulation are expanding rapidly.

Read MoreNPE 2003 News Wrap-Up: Hot-Runner Temperature Controls

Sophisticated hot-runner temperature controls introduced at the NPE show in Chicago store set-up data right on the mold, detect (and even fix) thermocouple wiring mistakes, and employ easier-to-use icon-based displays.

Read MoreNPE 2003 News Wrap-Up: Hot Runners

From complete hot halves to individual nozzles, a host of new products promise smaller gate vestiges, less maintenance, better temperature control, and lower cost.

Read MoreTandem Tools: New Twist on Stack Molds for Larger Parts

Two new tooling concepts adapt the idea of stack molds to producing larger parts that can be of dissimilar shape, size, color, or material.

Read MoreGet Custom Hot Halves in a Hurry

If you need a complete bolt-on hot-runner system on short notice, and off-the-shelf systems come up short in design flexibility, there's a solution available from Husky Injection Molding Systems of Milton, Vt.

Read More