k show

Breaking the Barrier: An Emerging Force in 9-Layer Film Packaging

Hamilton Plastics taps into its 30-plus years of know-how in high-barrier films by bringing novel, custom-engineered, nine-layer structures resulting from the investment in two new lines.

Read MoreExhibitor Registration Opens for K 2025

Exhibitor registration for the triennial event, which will take place Oct. 8-15, 2025, in Düsseldorf, Germany, is open with a reservation deadline of May 31, 2024.

Read MoreK 2022 Additives & Materials: Sustainability in the Lead

Nearly all of the new additives highlighted at the big show are aimed at enhancing recyclability of commodity resins and some volume engineering resins such as nylon and PC. A few new materials, on which we had not previously reported, also surfaced at K 2022.

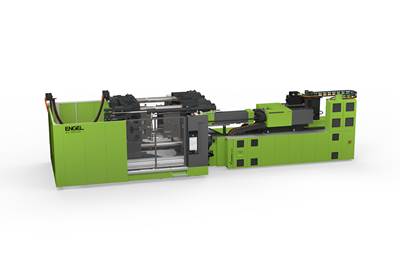

Read MoreEnergy Efficiency in Focus at K 2022

As much as cycle time, kWh/kg was an oft-cited metric by injection molding machine suppliers at October’s big show.

Read MoreSingle-Inlet Air Ring

Easy to maintain an operate, it’s integrated in the blown film line through just one cooling air supply line.

Read MoreUltra-Compact PET Machine For 12 L in Two Cavities

New size of all-electric reheat stretch-blow machine for large PET bottles debuted from 1Blow at K 2022. It retains the company’s signature small footprint and energy-sparing features.

Read MoreNew Designs for Electric & Hybrid Packaging and Industrial Blow Molding Machines

Introduced at K 2022, Bekum’s 21 models in the new EBLOW 8 Series and XBLOW designs include all-electric packaging machines from small to large, plus industrial units with a novel two-stage clamp in servohydraulic or hybrid versions.

Read MoreLarge Electric Shuttle for Coextrusion with PCR

At K 2022, Plastiblow showed the new all-electric PB50ES-1000 Coex3 machine making three-layer, 20 L jerrycans with PCR in the center layer.

Read MorePET Preform Molding Advances on Display

At K 2022, SACMI exhibited its latest PET preform injection molding machine, as well as quality control via integrated vision and rPET molding specialization.

Read MoreHow Was K 2022 for Blow Molding?

Over a dozen companies emphasized sustainability with use of foam and recycle, lightweighting and energy savings, along with new capabilities in controls, automation and quick changeovers.

Read More