Mold Maintenance

What Toolroom Maintenance Supervisors Need to Know

Those in charge of keeping molds reliable and production-ready normally start their day in the same manner—wondering what broke down since they last walked out the door—and hoping they have the resources to get it going again.

Read MoreWhy Mold-Maintenance Data Is Essential for Processing Technicians

When I was in the Navy, many different trades such as hydraulics, electrical, airframes, armament, and jet-engine mechanics worked side by side to get planes into the air, through their scheduled missions, returned to base, and turned around to do it all over again.

Read MoreDefect Position Analysis: What It Is, Why You Need It

There are so many new technological options in mold design, moldmaking, and molding today that it boggles the mind: We can simulate melt flows to anticipate difficulties.

Read MoreQualifying an Outside Molder? Look at the Tool Room

If custom molders were judged on curb appeal alone, this one would always be flush with work. Appointed in colonial brick encasing large smoked-glass windows and surrounded by balmy landscape and a lawn that looked good enough to eat, this stately plastics plant just screamed money. Surely they must be doing something right. But once past the glitz, the show was over.

Read MoreThe Final Check

The roar of fighter jets taking off one after another drowned out the frantic screams of the plane captain running towards me, but the look on his face made it obvious there was a problem.

Read MoreCreating a Mold-Repair Plan-Part II: The Last Shot Inspection Report

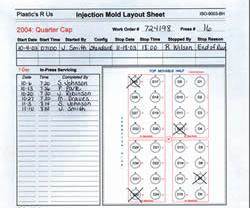

Last month, we discussed how to collect accurate mold performance data at the press through the use of an IML (injection mold layout) sheet.

Read MoreCreating a Mold-Repair Plan-Part I: The Mold Layout Sheet

Regardless of mold type, the goal of the maintenance shop always is the same: Get a mold production-ready after it has been removed from service.

Read MoreCleaning Molds, Part III Ultrasonics Make Life Easier

Is there a “perfect” cleaning system for molds and tooling that would allow a significant reduction in labor hours and tooling damage while providing consistent cleaning results?

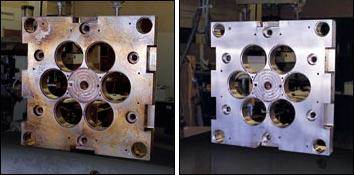

Read MoreCleaning Molds–Part II Blasting with Dry Ice

Today, the most popular method of cleaning plastic injection molds still remains rooted in the antiquated process of scrubbing tooling and plates by hand, one piece at a time.

Read More