Molds & Tooling

Mold Maintenance Hand Skills: It’s All about Connectivity

It takes a blend of brawn and brains for any tradesman or repair technician to become a craftsman or journeyman. And these skills can be learned.

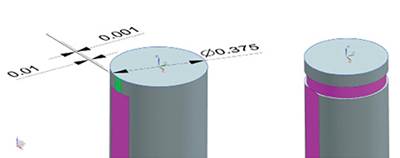

Read MoreA Very Small World: Micromolding at Makuta

Makuta Technics sweats the tiny details so it can run ‘lights out’ most of the day.

Read MoreSuperior Die Set Announces New Hire And A Promotion

Brandon Haffelder joins as a process engineer and Derrick Gilane, outside sales engineer, will now represent the company in Missouri, Kansas and Southern Illinois.

Read MoreEastman Explores Processing of Tritan Copolyester For Small, Multicavity Medical Parts

A sophisticated 32-cavity mold and all-electric press are being used to define the process window and critical mold and part design criteria.

Read MoreTooling at NPE: Valve Gates & Multi-Tips Top the News

There’s no letup in development of sophisticated hot-runner nozzles and controls. Here’s news in these and other tooling products at the show.

Read MoreOn-Site: A Big Molder’s Technical Engineering Plus a Small Company’s Customer Service

That’s the formula for rapid growth at a new/old firm serving medical, military, and aviation markets.

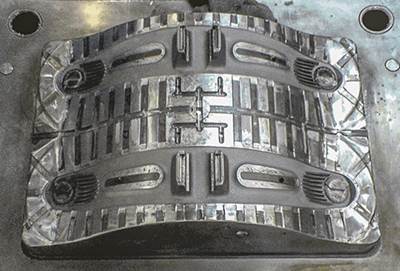

Read MoreTOOLING: How to Vent Mold Details

Principles to follow in venting bosses, ribs, pins, cores, slides, and lifters.

Read MoreTOOLING: Venting: Where And How Deep?

After last month’s introduction to the subject, let’s get into the details on vent depths, land lengths, and the alternatives to perimeter venting.

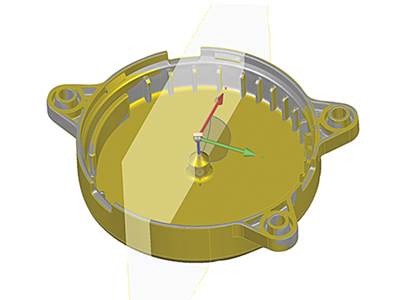

Read MoreCT Scanning Gives Precision Molder X-Ray Vision of Part Quality

It beats other techniques for measuring critical part dimensions, and it provides unique visibility inside parts, nondestructively. One molder’s experience illustrates the benefits.

Read MoreAmerican Injection Molding Institute: ‘A New Kind of Plastics Education’

Building 'foundational knowledge' and critical thinking skills.

Read More