monitoring

Fast, Simple, Low-Cost Method Unveils ‘True’ Melt Temperature

Long a mystery to injection molders, actual temperature of melt entering the mold is said to be revealed by an easy procedure that is repeatable and takes less than a minute.

Read MoreCoping with Coronavirus: What If You Can’t Get a Tech Service Visit?

‘Social distancing’ for service technicians? Online remote servicing to the rescue!

Read MoreExtrusion: Control System for Wire, Cable

System allows producers to maximize throughput while maintaining tolerances.

Read MoreInjection Molding: Pressure Transducer Enables Accurate Measurements at Low Pressures and High Temperatures

TrueMelt pressure transducers can provide accurate measurements for processes with pressures below 500 psi and temperatures above 300 F.

Read MoreInjection Molding: Artificial Intelligence Predicts Part Quality

AI software “learns” via DOE the influence of process variables on part quality and applies that “learning” to make good/bad part determination in production.

Read MoreFeeding/Blending: Controller Offers Connectivity & User Friendliness

Controllers for upstream volumetric mixers and dosing stations feature touch screen with extended recipe storage and management, among other features.

Read MoreHow Can Molders Achieve Effective Process Monitoring?

You have developed a proper process; now you need to monitor that process to ensure its stability through a run.

Read MoreExtrusion: Modular Control System for Blown Film

System can be installed on new line or on a retrofit basis to improve quality and cut resin costs.

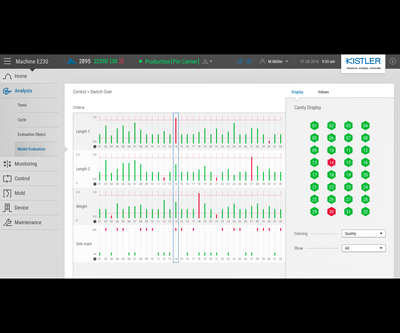

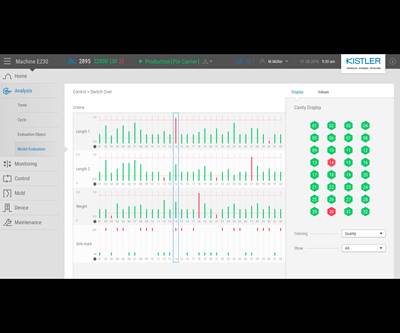

Read MoreInjection Molding: Tiny Cavity-Pressure Sensor Shrinks Further

Kistler’s ultra-compact sensor gets even smaller.

Read MoreInjection Molding: Making Melt Temperature A Useful Tool for Process Control

Portable, standalone data monitor replaces a laptop. Newest system uses melt thermal data to signal injection fill-to-pack switchover.

Read More