monitoring

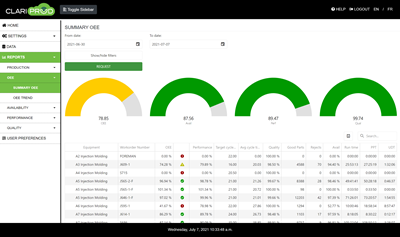

Real-Time Production Monitoring as Automation

As an injection molder, Windmill Plastics sought an economical production monitoring system that could help it keep tabs on its shop floor. It’s now selling the “very focused” digital supervisor it created, automating many formerly manual tasks.

Read MoreRadar Level Sensor Streamlines Bulk Material Inventory Management

NPE2024: The NCR-86 is designed to ensure rapid data updates, enhancing efficiency in inventory management.

Read MoreEigen Integrates Ampacet Color Monitoring into Machine Vision Solutions for Plastics

Injection molders, blow molders and extruders looking to avoid downtime and reduce scrap related to defect detection and color monitoring get a single solution for inline quality monitoring and management.

Read MoreFive Strategies for Cutting Reshoring/ Nearshoring Costs via Data Automation

Leveraging real-time data via tools like ERP and MES is one form of automation plastics processors can apply to capitalize on reshoring and nearshoring trends.

Read MoreIndustry 4.0 Without Fear: Modular MES Software Lets You ‘Start Simple’ and Add on Later

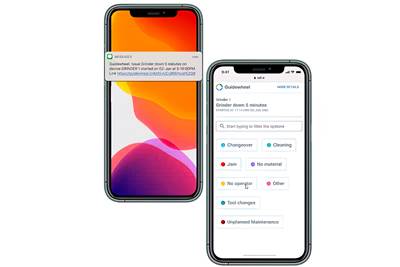

‘Don’t be afraid of MES.’ App-based platform can start with monitoring just downtime and cycle time on a few machines and add machines and functionality later.

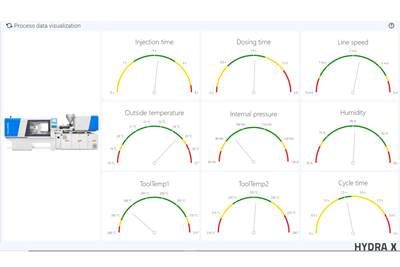

Read MoreManufacturers’ Superpower: ‘X-Ray Vision’ into Your Processes

Meet a ‘new’ name (to North American processors) in MES software, which provides a simple, modular way to achieve visibility into your production operations.

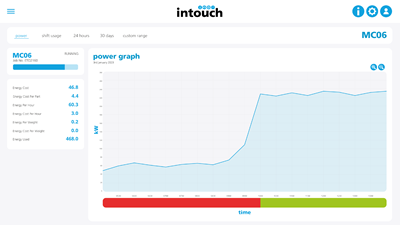

Read MoreSoftware Tracks Energy Waste in Real Time

Affordable add-on to production monitoring software alerts uses when energy is being wasted.

Read MoreUse Cavity Pressure Measurement to Simplify GMP-Compliant Medical Molding

Cavity-pressure monitoring describes precisely what’s taking place inside the mold, providing a transparent view of the conditions under which a part is created and ensuring conformance with GMP and ISO 13485 in medical injection molding.

Read MoreHow Machine Monitoring Delivers Tangible Results

Much more has been said than done about reaping the benefits of data driven manufacturing among plastics processors. Good technology is essential, but change management is the most difficult part of the process. Here’s how to think about both.

WatchHow Production Monitoring Can Make You a Better Processor

Real-time information on all your production equipment not only boosts productivity and profitability, but it encourages proactive vs. reactive thinking and sharing of best practices. See how this approach benefited a blow molder with 19 plants.

Read More