Postprocessing

Tips For Injection Molders: IMD Tooling & Robotics

Injection molders looking to get in on the IMD action should ask plenty of questions: What are the mold-design considerations?

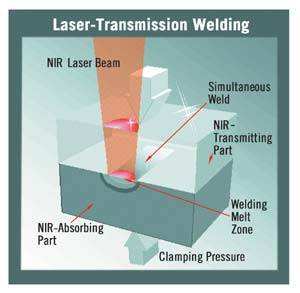

Read MoreLaser Welding Comes of Age

Laser welding is gaining acceptance as a specialized method for joining plastic parts that are sensitive (e.g., contain circuit boards), involve complex geometries, or have strict cleanliness requirements (medical devices). So far, most of this activity has taken place in Europe.

Read MoreFrom NPE 2000: What's New in Printing & Decorating

Recycled Resin Prices Flatten OutNew systems to process mixed plastic waste and to upgrade it with fiberglass or wood flour were prominent at last June’s show in Chicago.

Read MoreNew Polymer Uses Sunlight To Arm Itself Against UVDamage

Using sunlight to protect against sunlight—that’s the unusual concept behind GE Plastics’ new Lexan SLX polymer.

Read MoreHow to Thermoform Top-Quality IMD Inserts

Wider adoption of in-mold decorating (IMD) for demanding industries like automotive, appliances, and consumer electronics will require thermoformers to have the right know-how and equipment.

Read MoreWelder Is Super-Rigid For Extra Precision

Model 2050 is a 20-kHz ultrasonic welder designed to minimize deflection for precise joining of sensitive parts.

Read MoreThermoforming Troubleshooter: Avoid Pitfalls in Twin-Sheet Forming

Twin-sheet thermoforming is a promising but challenging process for making hollow or double-walled industrial parts.

Read MoreWhy All Eyes Are on In-Mold Decorating

Solid colors, woodgrains, brushed metal, or bright chrome.

Read MoreThermoforming Goes Paint-Free, Too

Thermoformed parts play two roles in the expanding field of in-mold decorating (IMD) of plastic parts: For injection molding, IMD begins by thermoforming a thin film into decorative shells that are placed in the injection mold cavity and then back-molded with a compatible substrate.

Read MoreWhere the Action Is: Decorating with Formable Films

Plastics processors are eyeing form able films as an economical, durable, and environmentally friendly means of producing fully decorated parts right out of the mold.

Read More