Sheet Extrusion

Switch to AC Drives & Save Energy, Maintenance Costs

Smaller, cooler AC packages can be retrofitted to existing lines to slash energy use and maintenance costs.

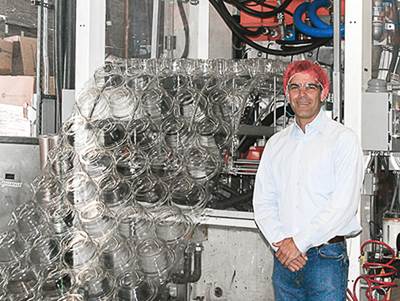

Read MoreThermoformer’s Name Change Reflects Refocused Strategy

New identity highlights processor’s focus on technology, product quality, and food safety.

Read MoreCheck Out the New Purging Compounds Knowledge Center

Get expert advice on how to solve black specks, color streaks and other quality problems.

Read MorePlastics Technology's Drying Supplement

Learn from the experts, including savvy processors, on how to get drying done right.

Read MoreGranulate or Shred: Which Makes Sense for You?

That is the size-reduction question confronting many processors today. Look here for some guidance.

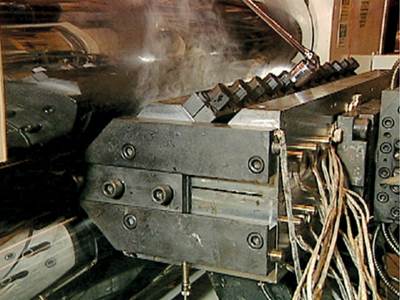

Read MoreEXTRUSION: Effect of the Screw Flight On Melt Temperature, Energy Use

So-called rules of thumb regarding the design of flight clearance and width do not consider the temperature effect, both from the point of view of melt temperature and energy efficiency.

Read MoreOctal to Start PET Sheet Extrusion in Ohio

APET sheet to be made exclusively from sheet flake.

Read MoreA Better Way to Balance Die Flow

Use temperature adjustments before making any mechanical tweaks.

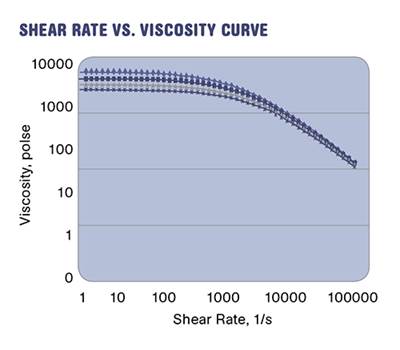

Read MoreCompounding PLA on Twin-Screws: What Testing Reveals

Twin-screw extrusion is the preferred method for compounding PLA and other biopolymers. But processing PLA is complicated because it’s sensitive to heat and shear. It’s also prone to hydrolytic degradation if moisture is present in molten PLA. Here’s what one machine builder’s trials revealed.

Read More