Testing

Part 1: Heat Deflection Temperature vs. Dynamic Mechanical Analysis

Does the industry need a better way of reporting the temperature-dependent behavior of plastics? With DMA, it already has one. But it’s been glacially slow to catch on.

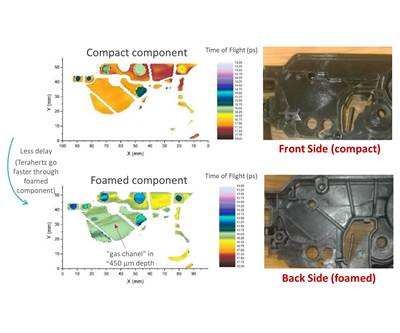

Read MoreNon-Destructive, Non-Hazardous Approach to Rapid Internal Inspection of Molded Parts

Terahertz spectroscopy allows in-line or off-line inspection of not only dimensions such as wall thickness, but also internal structure of solid or foamed parts.

Read MoreTesting: Vision System's New Lighting Technology Offers Greater Defect Detection Sensitivity

Omron’s upgraded FH-Series vision system can automatically detect small defects, uneven color changes and more.

Read MoreTesting: Melt-Flow Indexer Links Lab, Production Machinery

‘Groundbreakingly accurate’ machine features unified software platform between all laboratory and online production equipment.

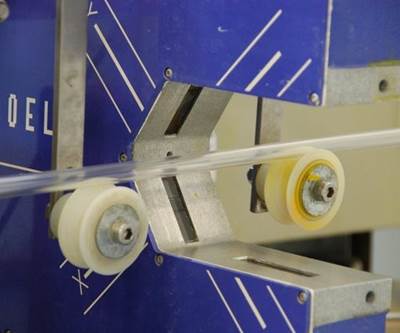

Read MoreMarposs Expands Non-Contact Measurement Offerings

Acquisition of Aeroel provides more measurement control options for extruded plastic products and more.

Read MoreTesting: FTIR Spectrophotometer with More Versatility & Reliability

Shimadzu’s IRSpririt is the smallest and lightest FTIR unit from the company.

Read MoreComputed Tomography in the Plastics

Computed tomography is an inspection technology that can be networked and used along the entire process chain.

Read MoreC.W. Brabender Showcases New Testing Equipment

C.W. Brabender is showcasing its new SpeciMold system, winder and torque rheometer.

Read MoreNPE2018 New Technology Focus: Robots Come to Materials- Testing Lab

Range of new testing machines include first-display of automated system that can run day and night.

Read MoreBlow Molding: Bottle & Preform Inspection Systems At NPE for First Time

Torus gauges measure wall thickness, neck finish, body dimensions, and perpendicularity.

Read More