Plastics Use in the Packaging Industry

Plastics are used to manufacture flexible packaging and rigid packaging in applications like caps, closures, bottles, film, and sheet.

ESSENTIAL READING

VIEW ALLHow to Extrusion Blow Mold PHA/PLA Blends

You need to pay attention to the inherent characteristics of biopolymers PHA/PLA materials when setting process parameters to realize better and more consistent outcomes.

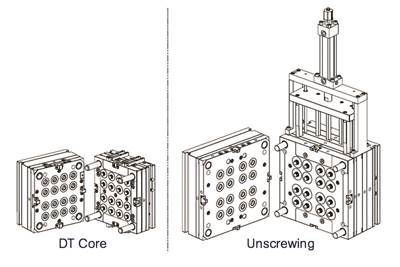

Read MoreBest Methods of Molding Undercuts

Producing plastics parts with undercuts presents distinct challenges for molders.

Read MoreSolve Four Common Problems in PET Stretch-Blow Molding

Here’s a quick guide to fixing four nettlesome problems in processing PET bottles.

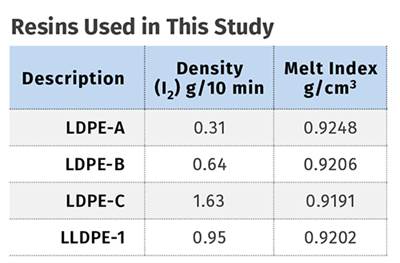

Read MoreFormulating LLDPE/LDPE Blends For Abuse–Resistant Blown Film

A new study shows how the type and amount of LDPE in blends with LLDPE affect the processing and strength/toughness properties of blown film. Data are shown for both LDPE-rich and LLDPE-rich blends.

Read MoreProtolabs Addresses How to Survive a Pandemic with Digital Manufacturing

Protolabs survey results examine product development and the supply chain.

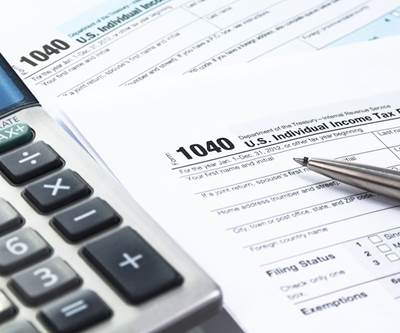

Read MoreWhat Plastics Processors Need to Know about Tax Reform and Equipment Acquisition

The Tax Cuts and Jobs Act of 2018 (TCJA) is positioning plastics processors for more growth and profitability following the most recent Plastics Processing Index showing the best quarter since 2013 when the index began.

Read MoreLatest Packaging News And Updates

Radial Wall-Thickness Control System Comes to the Americas

W. Müller USA now offers Feuerherm PWDS system for extrusion blow molding in North and Sourth America.

Read MoreHigh-Performance Resealable Lidding BOPET Film

Terphane’s Resealphane is the company’s latest innovation within its Selaphane product line.

Read MoreResearchers Find Foaming Bioplastics Reduce Environmental Persistence

Seawater testing shows rapid degradation for potential polystyrene substitute.

Read MoreUS Plastics Pact Updates Postconsumer Recycled Content Toolkit

Toolkit is intended to help converters to reduce virgin plastic consumption by incorporating recycled content.

Read MoreAll-Electric Stretch-Blower for up to 3L PET Bottles

PET Technologies debuts compact APF-Max 2L liner reheat machine with quick changeovers, NIR heating and blowing-air recovery.

Read MoreLighter, Higher Performance Base Design for Premium rPET Bottles

Sidel’s StarLITE-R Premium base for thicker rPET bottles ensures bottle stability in high-speed production, while saving energy.

Read MoreFeatured Posts

Research Deems Bioplastics, Wood Pulp a Sustainable, Economic Alternative for Rigid Packaging

Farrel Pomini and FPInnovations produce biodegradable compound for molding, extrusion and thermoforming applications.

Read MoreCustom Molder Pivots When States Squelch Thriving Single-Use Bottle Business

Currier Plastics had a major stake in small hotel amenity bottles until state legislators banned them. Here’s how Currier adapted to that challenge.

Read MoreFor Extrusion and Injection-Blow Molders, Numerous Upgrades in Machines and Services

Uniloy is revising its machinery lines across the board and strengthening after-sales services in tooling maintenance, spare parts and tech service.

Read MoreMultilayer Solutions to Challenges in Blow Molding with PCR

For extrusion blow molders, challenges of price and availability of postconsumer recycled resins can be addressed with a variety of multilayer technologies, which also offer solutions to issues with color, processability, mechanical properties and chemical migration in PCR materials.

Read MorePHA Compound Molded into “World’s First” Biodegradable Bottle Closures

Beyond Plastic and partners have created a certified biodegradable PHA compound that can be injection molded into 38-mm closures in a sub 6-second cycle from a multicavity hot runner tool.

Read MoreSee a 7-Layer Stretch Line Controlled by AI

Colines producing high-tech stretch film on a line with an artificial intelligence control package.

Read MoreFAQ: Packaging

The following are four other common issues, applicable to both single- and two-stage processes.

-

Pearlescence and haze

-

Insufficient top-load strength

-

Insufficient base clearance or rocker bottom

-

Drop-impact failure