A Custom Molder Takes the Next Step

The question John Winzeler keeps asking is, “How do you take the next step?” In the last two decades, he has transformed the Chicago metal-stamping company he inherited from his father into a high-tech specialty molding business focused only on plastic gears.

The question John Winzeler keeps asking is, “How do you take the next step?” In the last two decades, he has transformed the Chicago metal-stamping company he inherited from his father into a high-tech specialty molding business focused only on plastic gears. Through an emphasis on employee training and on joint-development partnerships with suppliers like Engel and DuPont, Winzeler has continually upgraded his shop, now called Winzeler Gear, to use the latest machinery and materials technology in everything from materials handling to molding and product inspection.

An NPE show debut

In an unusual move for a custom molder, Winzeler Gear participated in Engel’s NPE exhibit in Chicago this June, showing off Winzeler’s “next steps” toward more sophisticated automation and process control. A 60-ton, all-electric tiebarless Engel E-Motion machine exhibited a new feature that John Winzeler had conceived as a step toward achieving “zero-defect” molding. For the last few years, Winzeler employees have taken training courses in Decoupled Molding at RJG Inc. in Traverse City, Mich., and more recently some had achieved RJG’s Master Molder certification. Why couldn’t RJG’s eDart process monitoring—central to the Decoupled Molding philosophy—be integrated with the molding-machine controls, Winzeler asked. It would “clean up the machine” by eliminating some cables and probably bring faster control response as well.

By NPE time, a two-year effort by Engel and RJG resulted in Decoupled Molding screens appearing on Engel’s new CC200 controller—a first for any machinery OEM. This allows a processor to set individual profiles for filling, packing, and holding phases with cavity-pressure sensing to initiate the transitions between phases.

To show off the capabilities of this technology, Winzeler’s team cooked up a challenging demonstration of high-precision molding and a fully automated cell with secondary operations. It involved simultaneous molding of three oddly shaped gears—one triangle, one square, and one oval—of DuPont’s Delrin acetal and assembling them precisely with snap fits on a base plate so the three gears would intermesh smoothly. What’s more, one of the gears would be tested for size, concentricity, and profile error by placing it in a special gear-test apparatus before final assembly.

The family mold was built by Electroform Co. with a Mold-Masters hot-runner system. The cavities were filled using sequential valve gating with cutoff points signaled by RJG pressure sensors in each cavity. An articulating-arm robot from Kuka Robotics was paired with machine vision from Real Time Technologies in Canada. The robot also placed one of the gears in the test apparatus, where it is turned against a metal reference gear. “Nowadays, the only manual activity in our place is inspection,” Winzeler says. That’s why he wanted to prove that it can be automated right at the molding press. Although only a curiosity, the three-gear assembly proves another point: “It shows that we could assemble a gear box if someone wanted us to,” says Winzeler.

Coordinated automation

Back at the plant, Winzeler Gear has automated materials drying and conveying, parts handling, and inventory tracking through barcode printers and readers. Its most complex on-press automation project to date is a three-robot system for molding nylon 66 worm gears directly onto the spindles of small electric motors. One Engel beam robot removes eight motors from pallets and places them on a staging rack. During this transfer, the robot’s grippers slide wider apart because the pitch between cavities in the mold is larger than the spacing of the packaged motors. A second Engel robot inserts the motors into the tool in a 110-ton, electric tiebarless Engel press and simultaneously removes the overmolded motors. It sets down the motors on a rack, from which a third Engel robot packs them into boxes for shipping.

Related Content

How Inline Vision Inspection Can Minimize Scrap in Molding

Once viewed by injection and blow molders as a necessary evil, machine vision technology today can continuously monitor and improve production while reducing costs.

Read MoreDatacolor Acquires Matchmycolor

The acquisition of the specialist in color formulation and communication software further expands Datacolor’s global industry presence in color management.

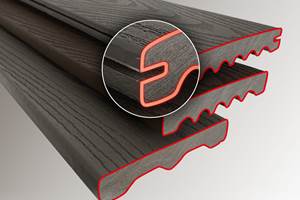

Read MoreInline Inspection System for Wood Plastic Composites

Pixargus’ ProfilControl 7 DX WoodPlasticComposites measure all dimensions and geometrics, including deep grooves.

Read MoreTracing the History of Polymeric Materials -- Part 30: Polyurethane

In the world of polymers, polyurethane chemistry is probably the most versatile. This a resulted in a wide range of products made from these materials and given the industry the flexibility to respond to the progressive march of regulatory concerns.

Read MoreRead Next

Making the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read More