AC Drives Take Hold

With progress in electronics and the introduction of the flux vector drive using complex control algorithms, AC drives are now equal to or better than DC drives for most applications.

In extrusion, DC drives were the standard for years. They can easily provide the torque necessary for startup. In fact, they exceedthe rated torque by up to 400% for startup with viscous or Newtonian polymers. Early-generation AC drives, by contrast, did not provide the high starting torque necessary for an extruder. They also did not provide the stable speed control necessary at low speed for some extrusion applications. Finally, AC drives were inefficient in the low speed ranges due to the high initiation current at low speeds.

But all of that has changed. With progress in electronics and the introduction of the flux vector drive using complex control algorithms, those disadvantages have been largely overcome. AC drives are now equal to or better than DC drives, with the possible exception of applications with requirements above 500 hp, where the AC drive components become very expensive. But AC motors under 500 hp are generally less expensive, smaller, lighter, more rugged, and require lower maintenance than their DC counterparts.

DC drives are internally cooled, requiring supplemental fans that need filtered air to prevent the inside of the motor from becoming fouled with particulates. AC motors are typically externally cooled, making them more suitable for the dusty environment likely in a plastics processing operation.

AC drive control tends to be more expensive than DC drive control because of its additional complexity. The variable-speed AC drive converts AC to DC and then back to AC current to control a normally fixed-speed motor, while DC drives make only a conversion from AC to DC current to control a variable-speed motor. However, AC motors are simpler and substantially less expensive, equalizing the cost of the motor/drive package. Moreover, AC motors are easier to install due to less complex wiring. Finally, the increased sales volume of adjustable-speed AC drives has reduced their cost compared to DC drives. As a result, AC drives now are almost universally installed on new extruders under 500 hp.

The biggest complaint about DC drives is their maintenance requirement. DC motors have brushes, which ride on a rotating commutator to form a rotary switch. This results in arcing, wear, and graphite dust from the brushes, requiring annual to semi-annual maintenance. Many DC motors have a sight glass to observe these conditions and to initiate maintenance. AC drives are brushless, but maintenance alone is not enough to justify changing to an AC drive.

The biggest reason to consider replacing a DC drive with an AC drive is the operating cost. The kilovolt-ampere (kVA) requirement for DC is about the same as for AC units. However, the phasing back of the semiconductor-controlled rectifier (SCR) in the DC drive, which is used to control speed, creates a poor power factor at low speeds. Most utilities charge for low power factor, as it requires them to have greater transformer and transport capacity for the same electrical usage. In many cases the power factor charge can approach 30-40% of the cost for the basic kWh in plants with a very low power factor.

AC variable-speed vector drives have a high power factor at all speeds, while DC drives have a power factor inversely proportional to the speed (see graph). If the DC drive is operating mostly at or near full speed, the power factor will be high and the economic incentive to change to an AC drive is greatly reduced. Conversely, a DC drive operating a low speed is subjected to the power factor charge and, depending on the utility’s price structure, may be economically ineffective.

One interesting difference in troubleshooting extrusion issues is that with a DC drive it’s very easy to determine the torque going into the extruder screw. Simply stated, if you use half the full-load amps, you are putting in exactly half the horsepower available at that speed. That’s not true with an AC drive, as the current is not proportional to the torque. With the early AC drives, that complicated any torque analysis; but with the newer drives the manufacturers have developed an algorithm that gives a motor load output that is proportional to the drive’s full load capability at that speed.

When considering a conversion from a DC to an AC drive the age, condition, operating speed, and utility charges all should be considered.

ABOUT THE AUTHOR

Jim Frankland is a mechanical engineer who has been involved in all types of extrusion processing for more than 40 years. He is now president of Frankland Plastics Consulting, LLC. Contact jim.frankland@comcast.net or (724) 651-9196.

Related Content

Troubleshooting Flow Surging in Single-Screw Extruders

Surging can cause lower production rates, higher scrap rates, material degradation and higher labor costs. Here is a guide to troubleshooting this problem.

Read MoreThe Role Barrel Temperatures Play in Melting

You need to understand the basics of how plastic melts in an extruder to properly set your process and troubleshoot any issues. Hint: it’s not about the barrel temperature settings.

Read MoreMaximize the Cooling Capacity of Your Extrusion Line

Maximizing output in extrusion requires a thorough understanding of not only the cooling requirements of the extruder but of the extrudate as well.

Read MoreUnderstanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so the barrel appears to be turning clockwise around a stationary screw.

Read MoreRead Next

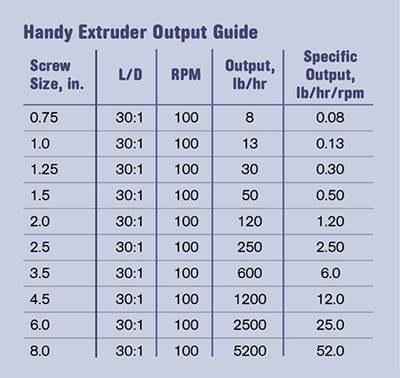

Get Smarter on Extruder Sizes

Processors tend to recommend a much larger extruder than what’s really necessary for the job and the capabilities of the downstream equipment.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More

.jpg;width=70;height=70;mode=crop)