Additives for Polyolefins: Newest Advances Add Ruggedness, Good Looks & Easier Processing

At a recent conference, suppliers revealed novel coupling agents for wood composites and nanocomposites, unusual nucleator masterbatches for OPP and thermoformed containers, and enhanced heat and light stabilizers, flame retardants, and processing aids.

Although a wide range of new additives were discussed at the SPE Polyolefins 2005 conference held in Houston earlier this year, one theme stood out strongly. This was the emergence of novel coupling agents to satisfy the growing interest in improved processing and performance for polyolefin natural-fiber composites and mineral-filled nanocomposites.

Other developments include a new light stabilizer that improves long-term heat and light stability, a new class of antioxidants that overcome limitations of conventional products, and a novel approach to address discoloration caused by phenolic antioxidants. Also new are a silicone gum additive for easier processing of filled polyolefins, unusual beta-nucleant masterbatches for polypropylene, and an improved low-smoke, non-halogen flame retardant.

Give wood fibers a boost

Dyneon has developed functional hydrocarbon-based block copolymers, based on proprietary "controlled-architecture materials" (or CAM, for short). They are being field tested in wood-plastic composites and polymer nanocomposites. Another potential use is polyolefin surface modification.

Project leader James Nelson explains that CAM is a way of controlling the structure of the polymer and the placement of functional groups in order to get the most effective additive performance. Dyneon's developmental compatibilizers for wood-plastic composites (WPC) are aimed at improving processing and surface aesthetics, reducing edge tear, and raising stiffness and tensile strength. "We are developing a broad array of these block copolymers, which provide interesting solutions to interfacial problems in all these areas," Nelson told the conference.

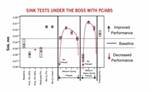

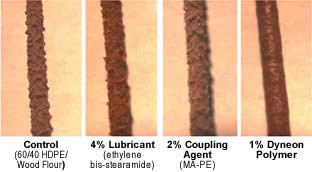

He reported on recent tests of a developmental additive package using one of the new functional block copolymers as the coupling agent, plus a 50/50 blend of zinc stearate/ethylene bis-stearamide as the lubricant system. The package was evaluated in both injection molded HDPE with 40% to 60% wood flour and in extrusions of PP board with 40% wood flour.

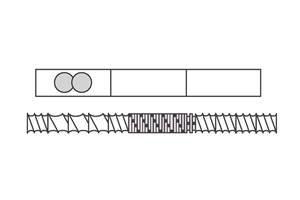

In the injection molded HDPE/wood samples, the new package was compared with a standard maleated-polyethylene (MA-PE) coupling agent on its own and with ethylene bis-stearamide lubricant alone. Results show a distinctly smoother surface appearance (see Fig. 1) with the Dyneon package, even at a total loading only half or one-fourth as large as the others. Flexural modulus and tensile strength were also greater with the Dyneon package, Nelson reported.

This additive system's efficiency was also explored in PP/wood profile extrusion. Initial findings indicate as much as 10% improvement in modulus of elastic rupture and a 50% decrease in extrusion pressure with the new package.

DuPont Industrial Polymers has introduced a new Fusabond coupling agent for PE/wood composites that is said to significantly boost strength and reduce water absorption at very low use levels. Fusabond W PC-567D is the result of new coupling technology that involves an ethylene copolymer with anhydride functionality incorporated in its backbone.

Said Megan O'Brien, marketing programs manager, "This latest advance allows us to build in much higher levels of anhydride than in our earlier grades. This creates more sites for chemical links between cellulose fibers and the polymer matrix, thus enabling a small amount of Fusabond W PC-576D to produce significant improvements in the composite's performance."

Recent tests of injection molded HDPE with 25% wood have shown that just 0.5% of this coupling agent can improve tensile strength and flexural strength (Fig. 2). In earlier trials with a typical highly filled extrusion formulation (HDPE with 55% wood), Fusabond W PC-576D at 0.5% loading produced a two-thirds reduction in water absorption after 30 days, a doubling of strength, and higher stiffness.

Crompton Corp. has pursued a similar goal of adding greater MA functionality with its new technology for producing MA-functionalized PP. With this process, the company has produced developmental maleated PP coupling agents that reportedly overcome the limitations of current commercial products in that they allow molecular weight and functionality to be varied independently. Moreover, the molecular-weight distribution of the starting resin is more closely preserved because of reduced chain scission during the functionalization reaction, according to Crompton research fellow William Sigworth.

Conventional coupling agents for PP natural-fiber composites are prepared by reactive extrusion. In this process, higher MA functionality leads to lower molecular weight of the final product. Sigworth says that has limited the amount of MA functionality that can be added to the polymer.

In 50% wood-filled PP, compounds made with the developmental coupling agents were compared with commercial coupling agents from several manufacturers. The samples made by the new process had lower MFR for a given level of functionality than the reactive extrusion samples.

Products made with the new process provided 66% to 70% higher flexural and tensile strengths than the control formulation with no coupling agent. Conventional coupling agents boosted flexural and tensile strengths by only 22% to 30% relative to the control. Moreover, the new-technology coupling agents provided higher flexural strength at 1% loading than the conventional coupling agents did at 2%. Reverse notched Izod impact strength of the developmental product samples also increased by an average of 124% versus the control, whereas the standard coupling agents raised impact by only 23%. Water absorption was also 39% lower in PP/wood composites made with the developmental coupling agents.

Coupling agents made with Crompton's new technology appear to be less adversely affected by lubricants. PP/wood composites made with these additives retained 90% of original flexural strength when a 75/25 blend of fatty acid ester and fatty acid amide was added, compared with 76% retention for the reactive-extrusion coupling agents.

Nano-compatibilizers

Dyneon is currently exploring "controlled-architecture," hydrocarbon-based block copolymers as compatibilizers and coupling agents for polyolefin and styrenic nanocomposites made by melt compounding montmorrilonite clay. According to Nelson, these developmental "CAM" additives provide good dispersion of the nanoclay and a strong interface with the resin matrix. "Efficient dispersion of the clays is often hindered by the natural incompatibility between the hydrophilic clay and the hydrophobic polyolefin matrices. In addition, the clay layers tend to bond strongly together, which makes the dispersion of the clay into the polymer matrix more difficult," explains Nelson.

Current additives that enhance the exfoliation and dispersion of organically modified clays include copolymers such as MA-grafted polyolefins for use with organically modified clays. Their main drawback is inefficiency: A fairly high level of additive is needed to exfoliate the clay. Dyneon has been developing a broad range of new, more efficient block copolymers containing amine, epoxy, anhydride, and acid functionality for use with a variety of clays.

For example, composites consisting of 5% of a CAM coupling agent, 5% of an organoclay (three were tested), and 90% PP were compounded in a twin-screw extruder. These nanocomposites were then compared with similarly prepared blends of PP with clay and 5% maleated-PP random copolymer.

X-ray diffraction studies reportedly showed that CAM nanocomposites were more efficient in aiding exfoliation of the clay and at significantly lower loadings (only 1%). In addition, the CAM-coupled compounds had 40% to 50% higher tensile modulus than the MA-PP composite (Fig. 3).

Fluoro surface modifiers

Dyneon has also developed migratory additive packages that can modify polyolefin surface properties at low loading levels. These additives include block copolymers of a fluorinated butenesulfonamide ethyl methacrylate, which can render polyolefinic surfaces hydrophobic or hydrophilic to impart anti-fogging, static dissipation, adhesion, compatibilization, paintability, printability, dyeability, and moisture wicking. Applications include carpet fibers, agricultural films, nonwovens, auto bumper fascias, packaging, hygienic products, incompatible resin blends, laminated articles, and eyewear.

New strides in stabilizers

Researchers at Cytec Industries have found that recently developed hindered hydroxybenzoate (HB) light stabilizers (non-basic forms of phenolic antioxidant) offer significant advantages in combination with primary and secondary antioxidants plus high-molecular weight (HMW) HALS light stabilizers. These stabilizer systems reportedly give polyolefins long-term thermal stability as well as moderate to very high light stability.

"Generally, the most effective long-term thermal stabilization systems are based on phenolic antioxidants in combination with thiodiester thermal antioxidants, such as our Cyanox STDP. However, when HALS are added to provide light resistance, the results are often unsatisfactory due to the antagonistic interaction between the HALS and thioesters," explains senior applications chemist Leonard Davis.

Hydroxybenzoate esters like Cytec's new Cyasorb UV-2908 have strong synergy with HALS and are not adversely affected by thiodiesters. Cytec says that makes them ideally suited to demanding requirements for both thermal and light stability.

Recent trials showed that addition of HB to injection molded PP containing a thioester (STDP) and HALS improves long-term thermal stability at both moderate and elevated temperatures and also boosts long-term uv stability. In this way, the total level of stabilizers can be lowered, since some of the SDTP can be replaced by HB, thus reducing the antagonism that would interfere with uv stability. By using HB, one can cut back on either the STDP or HALS or both to achieve the same level of thermal stability (Fig. 4).

Meanwhile, Polnox Corp. has developed a new class of high-performance antioxidants for polyolefins that boast significantly higher activity and lower migration than conventional antioxidants, reportedly resulting in longer service life for finished products. These macromolecular antioxidants, known as the Polnox PNX series, are also said to minimize yellowing.

In recent evaluations of oxidative induction time (OIT), the high-MW antioxidants PNX 102 and 103 performed better in extruded PP than a pentaerythritol-based industry workhorse antioxidant known by various names, including Irganox 1010 from Ciba Specialty Chemicals (Fig. 5). The stabilizing effect of PNX 103 is particularly striking at high concentration (5000 ppm), where it shows nearly three-fold better performance than the 1010 type. This suggests the ability to use two-thirds less antioxidant without sacrificing performance and thereby minimizing "phenolic" yellowing or pinking.

Albemarle Corp. has another novel approach for minimizing phenolic discoloration. Researchers discovered that a small amount (as little as 300 ppm) of Albemarle's "Poly A" polyhydric alcohol is an effective color-reducing additive when used with phenolic antioxidants in PP and HDPE. In recent evaluations of yellowness index in multi-pass extrusion of PP, 300 ppm of Poly A reportedly outperformed 600 ppm of either Albemarle's Ethaphos 326, a higher-cost phosphite used for high-color control, or Ethaphos 368, a lower-cost phosphite for low-color control. Slightly better results were obtained with a combination of both Ethaphos 368 and Poly A.

Silicone flow enhancer

A novel pelletized silicone gum from Wacker Chemical Corp., based on an ultra-high-MW (UHMW) polydimethylsiloxane, is reportedly very effective in improving the processing and flow properties of a range of thermoplastics, particularly filled polyolefins. With a higher concentration of UHMW silicone gum than conventional solid silicone additives, Genioplast Pellet S has also been shown to improve impact and tensile strength as well as surface smoothness and abrasion resistance.

In one test, just 0.2% of this additive increased the MFR of a 40% calcium carbonate-filled PP by more than 20%. Similar results were obtained in 60% ATH-filled EVA and LDPE. Lower melt viscosity allows for higher extrusion rates at lower pressure.

In another test, 1% of the additive nearly doubled the notched Charpy impact strength of 40% calcium carbonate-filled LDPE, HDPE, and PP. At 5% Genioplast S loading, impact was raised five- to eight-fold.

Beta-nucleant for PP

A new type of nucleator masterbatch for PP has been developed by Mayzo, Inc. It reportedly produces unique properties in OPP film and enhances properties and processability of molded and extruded products. Dr. Philip Jacoby, v.p. of technology, says most PP nucleating agents nucleate the alpha-crystal phase, the most common crystal form of PP. In injection molded or extruded PP, the alpha type accounts for over 95% of the crystals.

A less common form is the beta crystal form, which produces improved impact strength and ductility but lower tensile yield strength.

While there are many commercially available grades of alpha-nucleated PP, there are no beta-nucleated PP resins commercially available in the U.S. and only two fractional-MFR grades are produced in Europe for pipe.

Mayzo introduced two commercial beta-nucleant masterbatches last year. Both have a PP homopolymer carrier and contain only ingredients acceptable for food contact. They are priced competitively with high-performance alpha-nucleating agents. One grade, BNX BetaPP-LN, contains a lower level of the company's proprietary beta nucleating agent and is suitable for non-pigmented film and thermoformable sheet. It is typically added at a 2% to 3% loading.

The other grade, BNX BetaPP-N, contains a higher level of beta-nucleant and is also designed for use at 2% to 3% in situations where weak alpha-nucleating agents, such as certain pigments and additives, may be present in the PP and could interfere with beta-nucleation. This product is also suitable for compounders and resin producers, which can use levels as low as 0.25% to 0.50%.

Extruded PP sheet containing this masterbatch has very high levels of beta crystallinity. When subsequently stretched into monoaxial or biax film, the beta crystals transform into alpha crystals and develop microvoids. These microvoids scatter light, resulting in an opaque film whose density is reduced by 12% to more than 40%, depending on process conditions.

In thermoforming, beta-crystalline PP sheet has a broader processing window than conventional PP sheet, according to Jacoby. Beta-nucleated sheet has been formed into white/ opaque containers (Fig. 6), which are advantageous for dairy products because less TiO2 is needed to produce a uniform white color. Says Jacoby, "Generally we have found that the TiO2 level can be reduced by at least 50%."

Thermoformed beta-nucleated sheet also leads to enhanced sidewall thickness because beta-crystalline PP draws more uniformly than alpha-crystalline PP, and more material ends up in the sidewall region, Jacoby says.

The microvoids that occur during the drawing process lead to reduced sidewall density and a thicker sidewall. Resulting containers reportedly have higher rigidity and topload strength, allowing for downgauging. Beta-PP sheet also processes at shorter cycle times—as much as 17% shorter in one trial.

Mayzo has also found that when the beta-nucleant masterbatch is added at 2% level during injection molding, the molded PP parts have significantly improved impact strength at room temperature without adversely affecting stiffness.

New particle size for FR

J.M Huber Corp. has been developing new grades of magnesium hydroxide (abbreviated MDH) with various particle characteristics and surface treatments to optimize low-smoke, non-halogen, flame retardant polyolefin compounds such as EVA wire and cable jacketing. One new grade is Vertex 100, a 0.8-micron MDH with an intermediate particle-size distribution. When treated with a vinyl silane and used in EVA cable jacketing, the product reportedly outperforms existing MDH products with either silane or fatty-acid surface treatment.

Competitors that were tested include a 1-micron grade with narrow particle-size distribution, a 1.5-micron MDH with broad particle-size distribution, and a 4.5-micron size with intermediate particle-size distribution. All were compared by measurement of heat-release rate in a cone colorimeter (ASTM E1354) (Fig. 7).

In these tests, the Vertex 100 compound displayed a lower heat-release profile and also showed a later and lower second heat-release peak, suggesting more potent FR efficacy, according to Ton Chen, director of technology in Huber's industrial materials unit

Related Content

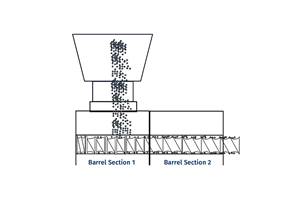

How to Configure Your Twin-Screw Extruder -- Part 2

Follow these tips to configure your twin-screw elements to promote feeding and solids conveying.

Read MoreStrategically Manage Pressure to Help Ensure Quality in Co-Rotating Twin-Screw Extrusion

Pressure measurement provides an invaluable window into any extrusion process, but it must also be strategically managed at every stage of the process to ensure a quality part is being extruded.

Read MoreMore Than a Compounder: They Have the Science to Create New Custom Materials

Insight Polymers & Compounders leverages its expertise in polymer chemistry to develop next-generation materials.

Read MoreConfiguring the Twin Screw Extruder: Part 4

For many compounding operations, material is fed to the extruder at the feed throat. This is the case when feeding a single polymer or a blend of polymers mixed with solid additives. Some ingredients, however, present a challenge in feeding. Here’s how to solve to them.

Read MoreRead Next

Wood-Filled Plastics: They Need the Right Additives for Strength, Good Looks, and Long Life

Wood-plastic composites, or WPCs, are already a 1.3-billion-lb market and are growing at 20% annually.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read More