Additives News at K 2013

More economical, higher performing, sustainable, and more finely tailored to specific applications—those features summarize the key advantages claimed for new additives showcased at K 2013.

More economical, higher performing, sustainable, and more finely tailored to specific applications—those features summarize the key advantages claimed for new additives showcased at K 2013. We reported on several of the new products in our show preview in September, but a slew more were at hand at the show.

HEAT STABILIZERS

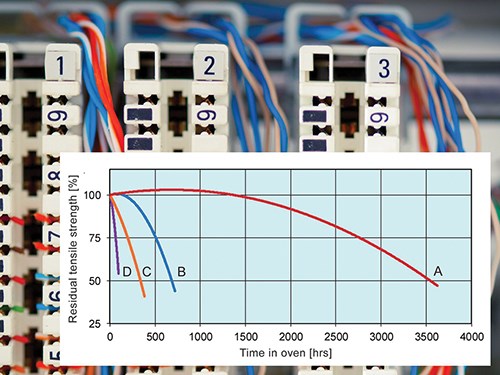

Color-stable, copper-based heat stabilizers for nylon 6 and 66 were launched by Brueggemann Chemical (U.S. office in Philadelphia). Bruggolen H3376 and H3386 meet requirements of E/E applications. Nylons stabilized with these products achieve Comparative Tracking Index (CTI) values of 600 V (H3376) or 575 V (H3386). These stabilizers reportedly offer longer-term thermal-oxidative protection, and at lower use levels, than antioxidants currently used in nylon E/E applications.

Dover Chemical, Dover, Ohio, unveiled its newest, “green” Doverphos LGP-11, a proprietary, high-molecular-weight liquid phosphite developed as a replacement for workhorse phosphite TNPP, particularly for polyolefin packaging where purity is an issue. This new antioxidant is unusual in that it contains no alkylphenols; displays excellent color performance, compatibility, and hydrolytic stability; and has low migration.

Also new from Dover is HMW, low-volatility, high-phosphorus-content Doverphos S-9228 solid phosphite. It’s said to provide unsurpassed hydrolytic stability, which prevents formation of black specs in polyolefins and engineering resins.

Five new stabilization packages make up the new Songxtend line from Songwon (U.S. office in Friendswood, Texas), which promises more robust and efficient processing along with outstanding performance in PP compounds. General-purpose packages 1101 and 1102 allow PP processors to maintain high-temperature manufacturing while retaining desired properties and avoiding degradation and discoloration.

Packages 2121, 2122, and 2123 are tailored for auto interior components. They are said to reduce VOC emissions and improve organoleptic properties by eliminating or reducing undesirable odors while maintaining high thermal stability. They greatly reduce or eliminate the need for odor-causing sulfur compounds.

Clariant Polymer Additives (U.S. office in Charlotte, N.C.) unveiled the first three AddWorks optimized additive packages. LXR 701, is designed for glass-filled nylons used in automotive, E/E, and building/construction. By improving melt flow, it is said to enable reduction of injection molding temperature by up to 30º C.

Clariant’s new ATR 301 and 302 packages are designed for automotive and transportation. ATR 301 boasts outstanding protection of filled PP during processing and excellent long-term aging properties. ATR 302 reportedly increases the long-term heat-aging performance of filled PP and provides better organoleptic properties than DSTDP thioester.

NON-PHTHALATE PLASTICIZERS

New and improved plasticizers based on dibenzoate chemistry were showcased by Emerald Performance Materials, Cuyahoga Falls, Ohio. K-Flex plasticizers provide a balance of high solvation and fast fusion compared with typical dibenzoate blends. PVC films plasticized with K-Flex reportedly show exceptional stain and extraction resistance.

Evonik (U.S. office in Parsippany, N.J.) launched the first of a new generation of plasticizers for sensitive PVC applications such as articles that commonly come into direct contact with the skin. Elatur CH is a 1,2-cyclohexane dicarboxylic acid diisononyl ester.

PIGMENTS AND COLORANTS

A new range of LHC (Low-Halogen Controlled) pigments and polymer-soluble dyes was showcased by Clariant. They were developed to meet EU product-safety regulations and industry standards for reduced halogen content. The 13 organic pigments and two dyes in the LHC series can be used for E/E, toys, consumer goods, and food packaging. The products are marketed under PV Fast, Graphtol, Polysynthren, and Solvaperm names with the LHC suffix indicating halogen content lower than 500 ppm.

Sukano (U.S. office in Duncan, S.C.) introduced highly concentrated white masterbatches that reportedly offer extra gloss, brightness, and opacity in PET containers, thermoformed trays, and thin films. In containers, they reportedly eliminate screw slippage and mold deposits, and in thin films they boast significantly improved light filtering. In thermoformed products, they allow for optimized color at low use levels.

ANTISTATS, CONDUCTIVE ADDITIVES & MORE

Cabot Corp., Boston, unveiled super-conductive carbon blacks for high conductivity at low loadings. The Vulcan XCmax series is targeted for use in wire and cable, antistatic flooring and safety systems, automotive fuel tanks and inlets, E/E products, and coatings. Also new from Cabot are its first conductive black concentrates, Cabelec CC6135 for PS and CC6277 for PE.

Akzo Nobel (U.S. office in Chicago) launched a highly filled concentrate of its vegetable-based Armostat 1800 antistatic additive for PP film and rigid packaging. Armostat 1800-XP75 contains 75% Armostat 1800 in a PP carrier.

A range of unusual high-performance antifog additives and masterbatches for food packaging and agricultural films are in development at Akzo Nobel. The first commercial product, Armofog 151, is said to improve hot and cold fogging performance of PE and EVA food-packaging films. Armofog 151-XE35 concentrate contains 35% of the new antifog additive.

Sukano is now offering new masterbatches for RPET, including an optical brightner, a melt-strength enhancer, impact modifiers, slip/antiblock, foaming agent, and special color masterbatches.

Styrolution, Aurora, Ill., introduced Styrolux 3G 46, a clear styrene block copolymer (SBC) as an impact modifier that maintains transparency in extruded sheet and film and thermoformed food packaging.

Wacker Chemie (U.S. office in Adrian, Mich.) launched its second Genioplast processing aid, a highly concentrated silicone additive (70% by wt.) on a silica carrier, in pellet form. Genioplast Pellet P is designed for food-contact applications.

Related Content

Multilayer Solutions to Challenges in Blow Molding with PCR

For extrusion blow molders, challenges of price and availability of postconsumer recycled resins can be addressed with a variety of multilayer technologies, which also offer solutions to issues with color, processability, mechanical properties and chemical migration in PCR materials.

Read MorePHA Compound Molded into “World’s First” Biodegradable Bottle Closures

Beyond Plastic and partners have created a certified biodegradable PHA compound that can be injection molded into 38-mm closures in a sub 6-second cycle from a multicavity hot runner tool.

Read More‘Monomaterial’ Trend in Packaging and Beyond Will Only Thrive

In terms of sustainability measures, monomaterial structures are already making good headway and will evolve even further.

Read MoreProcessing Megatrends Drive New Product Developments at NPE2024

It’s all about sustainability and the circular economy, and it will be on display in Orlando across all the major processes. But there will be plenty to see in automation, AI and machine learning as well.

Read MoreRead Next

K 2013 Preview: Materials & Additives

The K 2013 show will present a broad range of engineered plastics materials, including thermoplastic composites, as well as additives. Automotive and electronic applications will be the main targets, as well as medical, packaging, lighting, and construction.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read More