Air Ring Add-On Brings Output to New Level

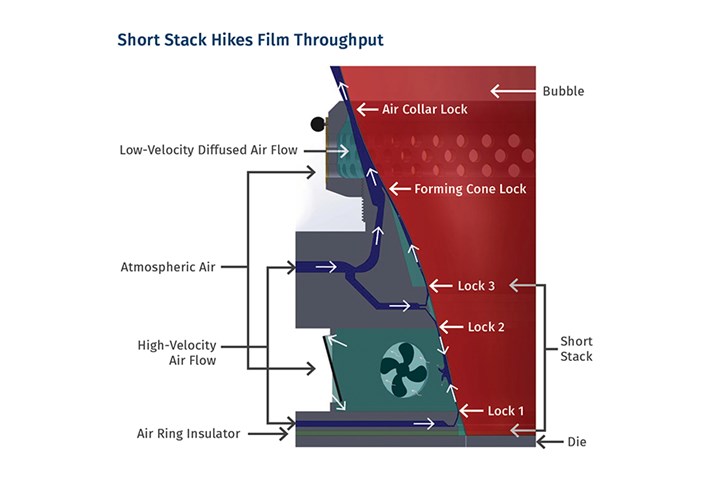

The Short Stack from Addex sits between the air ring and die and provides high-velocity air flow to boost output and lock in the bubble.

Pancakes aren’t the only thing that come in short stacks. Now blown film cooling systems do as well. New film-cooling technology from Addex is said to boost output by more than 25% vs. the company’s recently designed Intensive Cooling Down-on-the-Die (DoD) system, which has been shown to bump throughput by 10-15% over conventional designs.

Addex’s Short Stack will be officially unveiled at K 2022, Oct. 19-26 in Düsseldorf, Germany. The Short Stack is positioned directly under the air ring and sits flat on the die. Compared with so-called “raised-up” cooling rings, operators don’t have to worry about moving the Short Stack up or down, since its height is not adjustable. This simplifies operation. Says Bob Cree, Addex president, “The height-adjustable systems tend to be tough to start up; the bubble has to be pulled out and around oversized IBC hardware, which is required to push the tube outward into the air ring. Plus, they can be touchy to operate.” Cree, who co-invented the device along with Bill Randolph, Addex’s R&D manager, says the Short Stack facilitates startup by naturally pulling the bubble into an oversized air ring. The Short Stack can be run with or without conventional IBC hardware.

The Short Stack is fully integrated into the air ring. It uses air from the air ring directly, so no additional blowers or hoses are needed, and it is retrofittable to any blown film line. It removes the traditional lower-lip low-velocity air flow and instead provides three new high-velocity air flows and associated lock points to improve bubble stability. This reportedly allows for higher output rates and easier processing of lower-melt-strength materials.

Addex brought Intensive Cooling technology to blown film at K 2016 with a “blue box” system that featured a series of same sized stackable cooling elements that were also situated between the die and air ring. This was an extension of film-cooling technology Cree first experienced while working as a group leader in R&D for Mobil in the 1980s. Called the Herrington Stack (after its developer, Jack Herrington), the unit helped Mobil produce “billions of pounds of products,” recalls Cree, who worked for Mobil in Macedon, N.Y., for five years as a group leader in R&D before co-founding Addex in 1990.

The Addex short stack sits sealed to the die right under the air ring and is said to boost output by more than 25%. Images: Addex

The earliest application of the Intensive Cooling concept was a purely vertical design with two to four cooling elements. “The ‘blue box’ was a totally passive system, provided with a vacuum chamber enclosure that held the bubble out,” Cree explains. “The bubble stalked straight up through the system and into the same size air ring. Bubble stability and output gains were impressive, but soon it was realized that in a real plant environment the system was not particularly operator-friendly—not to mention that with multiple cooling elements, most lines ripe for retrofit could not handle the massive output gains that the system could deliver.”

This encouraged Addex to simplify the technology in 2017 with its Down-on-the-Die design, so named because it sat sealed atop the die, similar to a conventional dual-flow air ring. Unlike dual-flow designs, however, the DoD replaced diffused and low-velocity air flow from the lower lip, common in today's dual-flow air rings, with high-velocity air flow. Cree says the DoD proved more operator-friendly than its blue box predecessor as well as other conventional dual-flow air rings. What’s more, the high-velocity air stream added an additional stabilization point that locks in the bubble down low, allowing the blowers to be cranked up to increase output.

“Gone are the low-efficiency, low-velocity and very diffused air flows found at the bottom of dual- and triple-lip designs of today,” says Cree. Sealing the DoD air ring to the top surface of the die—absolutely no air gap—was another unique feature, he adds, and is important because it means that positive stabilization and high-intensity cooling can begin earlier in the process, literally just above the die lip, allowing hard-to-run films to run at higher speeds. Cree adds, “By adding cooling to the bubble down low, melt strength is immediately increased, which allows air flow to be increased at the main lip, dramatically increasing output rate without sacrificing bubble stability. This is what makes Intensive Cooling fundamentally different from other dual-flow air-ring designs—the aerodynamics are totally unique.”

Says Cree, “The increased stability of the process typically allows companies to use their old extruders up to their maximum capability, which for a majority of the retrofit applications was almost perfectly matched to the 10-15% output gains typical of these DoD systems. As an added bonus, it was soon discovered that this additional new lock point provided what some customers have termed ‘incredible’ stability that made it possible to run really low-melt-strength materials, which opened up entirely new markets for them, such as for certain barrier applications. In these applications stability is everything and the additional lock point that Intensive Cooling provides gives that capability.”

The Short Stack, which is in Beta phase in multiple plants, features three new stabilization points that guarantee bubble stability, two more than DoD, which means few, if any, adjustments are needed, even with material changes. More significantly, it means a less skilled operator can successfully run the line. Addex reports that the Short Stack is proving successful over a broad gamut of processes: larger blowup ratios and thin materials; smaller blowup ratios and thick materials; high-melt-strength and very low-melt-strength materials. Addex guarantees a 20-30% output increase for retrofits. Says Randolph, “It’s simple to use and no adjustments are needed over a wide range of processes, including low-melt-strength materials that typically are the bane of raised-up cooling systems, which just can’t process these resins.”

Cree further explains, “Due to the fundamentally different aerodynamics associated with Intensive Cooling, these systems create entirely new high-velocity lock points for added cooling and bubble stability, and also significantly strengthen the existing lock at the tip of the forming cone. Depending on melt strength, this added stability allows us to put even more air on the process, which yields even more output and stability.”

DoD designs are still available. Addex terms that technology an “entry level” into Intensive Cooling, with the Short Stack representing a further step up.

Related Content

What to Know About Your Materials When Choosing a Feeder

Feeder performance is crucial to operating extrusion and compounding lines. And consistent, reliable feeding depends in large part on selecting a feeder compatible with the materials and additives you intend to process. Follow these tips to analyze your feeder requirements.

Read MoreHow Screw Design Can Boost Output of Single-Screw Extruders

Optimizing screw design for a lower discharge temperature has been shown to significantly increase output rate.

Read MoreTroubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read MoreHow to Select the Right Tooling for Pipe Extrusion

In pipe extrusion, selecting or building a complementary set of tooling often poses challenges due to a range of qualitative factors. Here’s some guidance to help you out.

Read MoreRead Next

Stackable Bubble-Cooling Rings Offer Huge Output Gains

Next-generation bubble-cooling system is said to boost throughputs by as much as 60% in blown film.

Read MoreFilm Extrusion: Towers of Power & Sustainability

At K 2019, developments in blown film highlighted recyclable film structures for new applications and technology aimed at making product changes more efficient.

Read MoreAir-Ring Upgrade Pumps Up the Output

Film processor Dallas Plastics boosts throughput by as much as 40% by retrofitting a new air ring—without the need for IBC.

Read More