B&B Molders Sticks to Its Core— Core Values & Core Competencies

To compete in today’s market, you need good technology, but you also need to know what you stand for and what you’re good at.

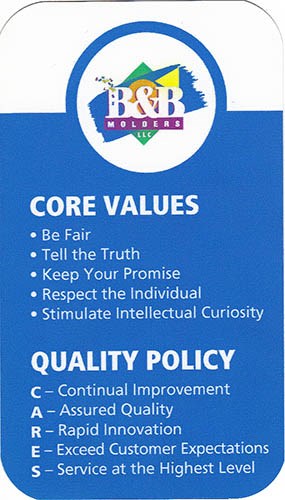

B&B has its core values printed on a business-card-sized slip of plastic:

• Be fair.

• Tell the truth.

• Keep your promise.

• Respect the individual.

• Stimulate intellectual curiosity.

The first two points are reflected in the company’s quality policy. “We compete on quality,” says production manager Ralph Dalton. “Our scrap rate is 0.75% of sales and heading lower. That’s world-class.” For comparison, he says that in the auto industry, scrap at 1.2% of sales is considered very good. The quality focus is reflected in the company’s custom-printed blue shipping boxes with the logo, “B&B Molders ISO Certified.”

B&B’s core values were put to the test during the recession of 2008-2009, when it lost 63% of its customers and 45-50% of its revenue. Salaried employees took a 20% pay cut. There were layoffs. “We had to cut expenses—eliminate everything that was not essential to actual operations,” Murphey recalls. For nine and a half months, he and his wife cleaned offices, mopped floors, cleaned toilets.

CORE COMPETENCIES

B&B prides itself on its product-development capabilities, one of the factors that distinguishes it from low-cost overseas competition. “We like engineered parts, and we like to develop the part for the customer up-front,” says Jim Krezel, operations manager. “A lot of people come in here with nothing more than a napkin sketch of their product idea.” And not just individual entrepreneurs—even mission-critical jobs for large defense contractors can start that way.

now, the upstairs level of the assembly area is devoted to a secret project that Krezel says will revolutionize one aspect of RV and motor-home design and add to consumers’ convenience.

Murphey is quick to point out another benefit: “Mold analysis helps us do a much better job of estimating cycle time so we can be more competitive in pricing a job!”

Another competitive advantage is B&B’s in-house toolroom. “Tooling is the heartbeat of what we do,” says Murphey, who notes that the firm started as a moldmaking shop in 1963, and only later got into molding at customers’ request.

The toolroom currently employs nine people and operates three CNC vertical milling machines, a wire EDM, a CNC/EDM sinker, two Bridgeport milling machines, four surface grinders, and a lathe. Another CNC machine may be coming in the next year. The company builds around 30% of its molds, a number that’s heading toward 50%. “Our goal is to build 70-80% of our tools,” says Rick Layher, toolroom manager, “because it gives us better control and we can build molds for 25-30% lower cost than buying them outside.” One reason, he explains, is that B&B does a lot of overnight machining on a lights-out basis,

and an outside vendor would charge for all that machine time. “We can compete with

China on an equal-quality basis,” Layher asserts.

Like other molders, B&B has had customers pressure it to buy low-cost Chinese molds. Recalls Murphey, “Once it got here, it cost a bundle to get the ‘cheap’ mold up and running—and that was after it was quarantined offshore on a ship because the crew came down with flu!” After that first disastrous experience, B&B found a local moldmaker that has its own mold shop in China. B&B tried out a mold from that source—built to U.S. standards—and the result was encouraging.

B&B gives its molds a lot of TLC. After a job, a mold is taken apart, cleaned, re-lubed, inspected for nicks and scratches, repaired if necessary, and labeled with a tag that says it’s ready to go the next time the job comes up. That’s important because B&B does four to five mold changes a shift, 12-16 in 24 hr, quite a lot for a shop with just 15 presses.

With its growing volume of business, B&B relies increasingly on automation to meet its productivity goals. All presses now have sprue pickers to free up the operators; and with hot-runner molds, the pickers can sometimes be used to pick parts instead of sprues. The firm’s largest machine carries the first three-axis beam robot in the plant, which arrived three months ago.

The assembly department uses several automated cells, which perform up to a dozen operations to assemble valves from up to eight components and add a pressure or vacuum test at the end.

“Nine years ago, I said I wanted to develop a scientific approach to molding at B&B,” recalls Murphey. “We had a lot of nay-sayers at first. People said, ‘We already make perfectly good parts.’ But there was no real molding expert here, just guys who could shoot parts but didn’t really understand the process.

“We had a lot of older equipment then. There was too much turmoil and excuse after excuse about why we couldn’t make parts. I was frustrated.

Scientific Molding at his previous employer.”

“But the real trick is being with the trainees on the floor and at the machine,” says Bubanovich. “You have to hang out with them while they learn Scientific Molding until it becomes automatic for them. It takes a couple of years before they are comfortable with it. The way I sell people on the idea that it’s all worthwhile is that Scientific Molding is about ‘grief relief.’ It saves you a lot of grief.”

What does Scientific Molding mean in practical terms? “It means that when the job goes in the press two weeks from now, it will run the same way,” says Krezel. “It helps you start up quicker, run faster cycles—with less scrap—and troubleshoot faster. When something changes, you know how to find out where and why.”

For each new job, Phase I is to take initial samples using short shots to determine the proper transition point from filling to pack and hold. Careful examination of parts in the QC lab helps determine what process settings produce the best dimensional stability. Then comes Phase II,

or “Safe Launch,” in which a low-volume production run is initiated to make sure the process is capable of maintaining consistent quality.

“Nowadays we tend to run off numbers instead of gut feel,” adds Bubanovich. “We’re a more data-driven organization. We look at injection pressures and ask, ‘Why is it different?’ It took five years to get everybody there and get the data recorded and get people looking at the data.”

Bubanovich says a new training program will be required once B&B installs a real-time production and process monitoring system from IQMS. Soon, all the company’s injection presses will be tied into the central monitoring system to record uptime, downtime amounts and causes, cycle times, scrap rates and reasons. Operators will be able to enter barcode scans for each box of product filled. Such data are manually recorded now, but the automated system will free up operators’ time and prevent errors, says Dalton.

INVESTING IN TECHNOLOGY

B&B Molders is also investing in processing hardware to improve productivity, product quality, and quality of the work environment. The latter is an important focus for the company, notes Krezel. He points to the last three machine purchases—all-electric and hybrid presses

from Nissei and Sodick Plustech. He expects to keep going in that direction for the sake of quietness, cleanliness, and energy efficiency. Their precise repeatability, he adds, allows B&B to run faster cycles while maintaining part quality.

Most of the scrap granulating takes place in a special room to keep noise and dust out of the work area. And to prevent material cross-material contamination, there’s even a separate room for cleaning the granulators.

Krezel and Murphey are especially proud of a $450,000 Resin Works central drying and conveying system from Conair, installed one year ago. The system has three dryers, each supplying a row of 10 drying hoppers with individual temperature and airflow control.

For especially critical jobs, such as a clear polycarbonate lens, B&B still uses individual portable dryers at the machine to avoid even the tiniest bit of crosscontamination, which shows up easily in clear parts.

Accompanying the drying system is a Conair central material distribution system with a manifold for dry-air conveying of up to 40 materials to the plant’s 15 machines. The manifold uses flexible hoses for each machine destination that are coupled manually to material source ports. The couplings are linked electronically to the main controller, which will not allow a material other than the one specified for the job to be conveyed to a machine.

Related Content

Design Your Tools for Moldability ... and Maintenance

In the initial design phase, when considering the structure and elements of the tool, are you designing them to be maintenance friendly? Canon Virginia has used this approach and preventive maintenance to make tool replacement a thing of the past. You can, too. Here’s how.

Read MoreWhat You Need to Know About Leader Pins and Bushings

There’s a lot more to these humble but essential mold components than you might suspect. Following the author’s tips could save much time, money and frustration.

Read MoreHow to Start a Hot-Runner Mold That Has No Tip Insulators

Here's a method to assist with efficient dark-to-light color changes on hot-runner systems that are hot-tipped.

Read MoreBack to Basics on Mold Venting (Part 1)

Here’s what you need to know to improve the quality of your parts and to protect your molds.

Read MoreRead Next

Savvy Processors Reveal Best Practices on Drying

The processors speak: Here’s how some smart molders and extruders tackle the vexing problem of resin drying.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read More