Beaumont Tech Buys Material Characterization Business from Autodesk Moldflow

A trainer in mold analysis and supplier of simulation services acquires testing facilities used to obtain materials data needed for accurate simulation.

Beaumont Technologies Inc., Erie, Pa., has expanded its range of services by acquiring the material characterization business of Autodesk MoldFlow serving North America and Europe. The operations, laboratory equipment, and proprietary software will be transferred from Ithaca, N.Y., to a new facility in Erie.

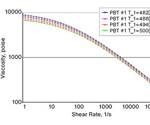

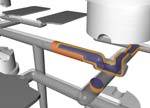

The material characterization services to be conducted by Beaumont are used to determine essential material properties for accurate molding analysis by Autodesk MoldFlow and other simulation software. The tests include both specialized proprietary Autodesk methods and more conventional material characterization techniques. Autodesk will maintain its materials testing and development lab in Australia to serve customers in Asia and other global markets, as well as for its own research.

“Beaumont’s American Injection Molding Institute is the preferred training partner in North America for our injection molding simulation customer,” says Greg Fallon, Autodesk’s v.p. for simulation. “With Beaumont handling the majority of our training and material characterization activities, Autodesk will focus on development and validation of new process solvers and characterization methodologies.”

Beaumont Technologies’ founder, president, and CEO John Beaumont, is professor emeritus at Pennsylvania State University in Erie and was formerly technical manager for MoldFlow’s U.S. operations in its early years. He invented the MeltFlipper and Therma-flo moldability analysis, a specialized form of material characterization.

Related Content

-

Design Your Tools for Moldability ... and Maintenance

In the initial design phase, when considering the structure and elements of the tool, are you designing them to be maintenance friendly? Canon Virginia has used this approach and preventive maintenance to make tool replacement a thing of the past. You can, too. Here’s how.

-

Back to Basics on Mold Venting (Part 2: Shape, Dimensions, Details)

Here’s how to get the most out of your stationary mold vents.

-

Hot Runners: Truths. Myths, Overlooked Areas: Part 2

Here’s a view from the trenches of a tooling manager who, over 30 years, has experienced the joys and pains of using virtually every type of hot runner on the market. Part 2.