Cobots Help Molder Find ‘Right Balance’ Between People and Automation

Short-run, quick-turn custom molder uses collaborative robots selectively to make people more productive.

Donnelly Custom Manufacturing is a short-run, high-mix custom molder that performs more than 40 mold changes a day on its 37 injection machines to serve customers’ low-to-mid-volume needs (see previous articles in March ’15 and Sept. ’12). One of its key challenges is learning where and how to automate jobs that may run only a few hours.

As explained by president Ron Kirscht, this ongoing learning curve is prompted by a string of record sales years—$36.2 million in 2018—which keeps Donnelly’s Alexandria, Minn., plant hopping, even with the addition of two new presses last year. “We need to be agile while leveraging our short-run expertise to manage effectively and save time in critical processes, both setups and production runs.”

For more than a decade, Donnelly has been adding robotics, so that all its machines above 140 tons have Cartesian-style parts removers, which free up employees for more value-added tasks at the press, like welding, decorating, and machining. In the last five years, Donnelly has also explored the new field of collaborative robots, or cobots. It began by installing two Baxter cobots from the former Rethink Robotics (now out of business; its technology was acquired by Hahn Group of Germany). Donnelly employs them in simple pick-and-place tasks, such as packing or clipping sprues. “Packing boxes takes the equivalent of half an operator’s time,” says Kirscht. “The Baxter can do it and keep count without need for weighing the boxes.”

GOING COLLABORATIVE

Last year, Donnelly explored what further potential cobots could offer in more sophisticated sequential operations. The firm bought its first UR5 cobot from Universal Robots. Says Jerry Bienias, Donnelly’s v.p. of operations, “We were able to visit CNC machining shops in our area that use several UR cobots. We could see that they are more capable than the Baxter in speed, precision, and ease of programming.”

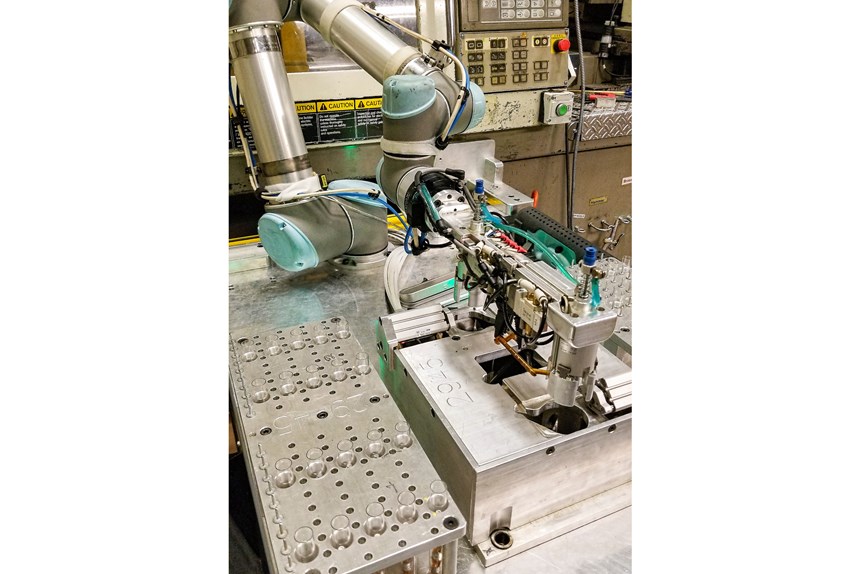

Donnelly put the UR5 to work loading two tiny inserts into a two-cavity mold, and then removing the parts, clipping the gates, and dropping the parts into tubes in a box, five parts per tube. This is accomplished within a 40-sec cycle with the aid of end-of-arm tooling (EOAT) developed by Donnelly to enable the cobot to accomplish all these operations with one EOAT. As a result, a cell that formerly required one and a half operators now requires only half an operator’s time. (See it in action at http://short.ptonline.com/Donnelly.)

Bienias says Donnelly will probably stick with UR cobots for future purchases. The Baxter cobot (which is no longer on the market) was not up to the task of insert loading, due to arm shake, he notes, adding, “We still love the Baxter. It was our launching pad into a new world of collaborative robotics.”

Though one merit of cobots is supposedly their ability to operate safely around people, there are limitations to that principle. Donnelly has hard guarding around the area of the EOAT that handles the parts being molded because they have sharp edges that could cause injury through accidental contact.

Cobots are also touted for their ease of programming, using a “lead-through teach” method. Bienias notes that accurate setup of the UR5 is essential for insert loading. One factor is the mold, oil heated to 380 F, which expands as it heats up. The UR5 cobot, mounted on wheels, is bolted to the press, and special setup EOAT that closely matches the production version is used to “teach the robot where the mold is in space,” by means of locating pegs on the mold, Bienias explains. In 5 to 10 min, the cobot is oriented sufficiently to place the inserts within a couple of mils.

Though Donnelly is quite happy with its evolving utilization of cobots, Kirscht points out that “people continue to perform the majority of critical manufacturing tasks here. Automation helps us better understand the nature of the tasks performed by humans so that we can identify opportunities to strike the right balance between people and automation.”

Related Content

New Facility Refreshes Post-Consumer PP by Washing Out Additives, Contaminants

PureCycle prepares to scale up its novel solvent recycling approach as new facility nears completion.

Read MoreSystem Offers 'Lights Out' Mold-Channel Cleaning & Diagnostics

New system automatically cleans mold-cooling lines—including conformal channels—removing rust and calcium, among other deposits, while simultaneously testing for leaks, measuring flow rate and applying rust inhibitor.

Read MoreExtrusion Technology Extended to Injection, Enabling Up to 100% Regrind Usage

Twin-barrel (shot-pot) press can handle more regrind, offers other benefits to molders.

Read MoreNew Blown-Film Cooling Technologies Set to Debut at NPE2024

Cooling specialist Addex to roll out new auto-profiling air ring for rotating dies, and new single-plenum air ring.

Read MoreRead Next

Making the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read More