Custom Molding Still Recovering

Custom injection molders continued their recovery from the Great Recession of 2008-2009 in the second half of 2010, though at a slower rate than in the first half.

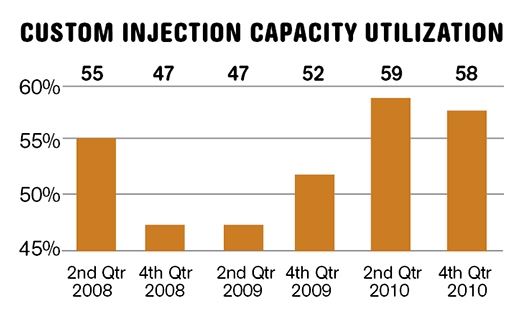

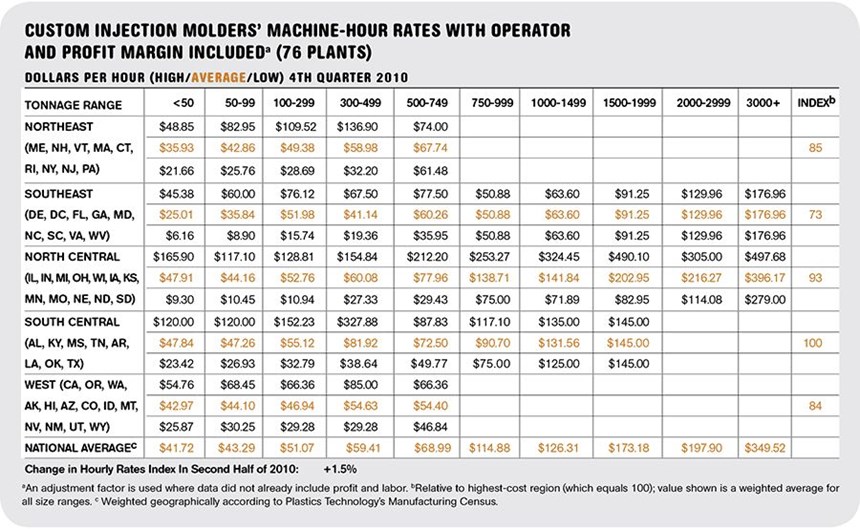

Custom injection molders continued their recovery from the Great Recession of 2008-2009 in the second half of 2010, though at a slower rate than in the first half. Survey responses from 76 plants showed that machine capacity utilization in December of last year was 1.4 points lower than in June, but still well above ’08-’09 levels. By this measure, molders in the Northeast were busiest and those in the West least busy—the same as in the first half of 2010.

Just over 22% of respondents increased capacity utilization in the second half, while almost 40% saw lower utilization and 37% stayed the same. In the first half, the proportions were around 60/20/20.

Our Hourly Rates Index rose 1.5% in the second half, about the same as in the first half. Some of the biggest rate increases were in big machines, perhaps reflecting the resurgence of the auto industry.

Reports from 40 mold shops indicated a 0.9% rise in new tooling orders for the fourth quarter, well down from the surge in the second quarter.

OPTIMISM STILL HIGH

Almost 65% of respondents surveyed in January expected business conditions to improve in the near term, while only 8% expected worsening conditions, and 25% foresaw no change.

Related Content

-

Back to Basics on Mold Venting (Part 2: Shape, Dimensions, Details)

Here’s how to get the most out of your stationary mold vents.

-

Back to Basics on Mold Venting (Part 1)

Here’s what you need to know to improve the quality of your parts and to protect your molds.

-

Optimizing Pack & Hold Times for Hot-Runner & Valve-Gated Molds

Using scientific procedures will help you put an end to all that time-consuming trial and error. Part 1 of 2.