External Gas Molding Squeezes Out Sinks

External gas injection is finally getting molders’ attention as a means to improve part surface quality. Two different approaches are available for licensing. Here’s a look at the processes, the potential benefits, and the commercial players.

Injection molding a part with Class-A surface finish and ribs or bosses has proven an elusive goal for molders, despite their best efforts with conventional injection or internal gas-assist technology. Yet demand is rising for sink-free surfaces over ribs and bosses in products for a wide variety of industries. Demand is particularly keen in thin-wall applications such as cell phones, automotive body side moldings, car interior panels, and computer monitors. Besides thin-wall parts, suppliers say external gas molding has its greatest potential in large, flat parts such as cover panels, housings, fascias, and grilles.

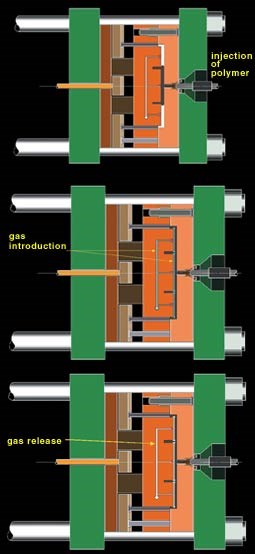

Two alternative process technologies designed to remedy molded surface imperfections have been available since the early 1990s. One approach applies a gas to one exterior surface of the part after the mold has been filled about 98-99% with melt. The gas enters the mold from the core side and presses the critical appearance surface against the opposite mold face. Another method is a gas counterpressure method, in which a gas (air) is used to prepressurize the mold before melt is injected to ensure continuous pressure of melt against the mold before the cavity fills. Both approaches act to hold the material to the mold surface while the melt cools. “They affect the material in a way similar to compression molding,” says Juergen Ehritt, process engineering and development manager at Battenfeld.

Three external gas injection techniques are being promoted by five firms in the U.S.: the Airmould Contour process from Battenfeld of America; external gas molding technology developed by Asahi Kasei Corp. in Japan and licensed to Incoe and also Cinpres Gas Injection (CGI) Inc.; and the IntelliMold process, a gas counterpressure method offered by Textron Automotive through its IntelliMold Systems Div.

Although adoption of external gas technology has been slow in coming, suppliers report growing interest by molders—interest that is impossible to verify because of customer secrecy. “We have a dozen applications that are active and commercial right now, but all are proprietary,” says John Blundy, v.p. of business development at Incoe.

Textron says it has three commercial IntelliMold gas counterpressure applications at its own Trim division in Troy, Mich. That operation now has 24 presses equipped for IntelliMold—most of them over 1000 tons— and plans to have a minimum of 100 systems installed on its machines by the end of this year, says Jerry Mosingo, executive v.p. of manufacturing. More than a dozen licenses for the process were issued to other firms before Textron bought the technology last year, along with its original developer, M&C Advanced Processes of Ann Arbor, Mich.

CGI’s External Gas Assist process has a number of commercial applications in Europe and Asia, and at least one North American molder is looking into it for an automotive application, reports Terry Pearson, chairman and director. CGI was created in August from the merger of two U.K. companies—Cinpres, a supplier of internal gas-assist technology, and Gas Injection Ltd., an early promoter of Asahi’s external gas method. Pearson says Asahi Kasei has issued 30 licenses for the technology since the mid-’90s. “Several applications are being developed for automotive parts where sink marks cannot be eliminated by any other means,” Pearson says.

Battenfeld’s Ehritt says its external gas process is used commercially in North America, but the details are proprietary to the customer.

Breaking through

Internal supporting structures of a part are typically thicker than the external part wall and therefore cool more slowly. This difference in cooling creates internal stresses within the part that can show up on the part surface as sink marks, blemishes, indentations, shiny spots, and warpage. “When the structural section [rib or boss] cools, it pulls the material around it due to normal volumetric shrinkage, attracting material that is on the surface of the part,” Incoe’s Blundy explains.

Internal gas assist has been used to solve sink problems by making the ribs even thicker and then partially hollowing them out with gas. Drawbacks of this approach are said to include the likelihood of higher material usage, higher packing pressures, and longer cooling times—with still no guarantee of sink removal.

These concerns have opened the door to external gas injection. Besides solving surface-quality problems, which may also eliminate downstream painting, external gas techniques can yield a variety of process benefits. One is the reduction or elimination of pack and hold phases of the cycle. “At least 50% of the clamp tonnage is needed for the packing phase,” notes Battenfeld’s Ehritt. Packing is accomplished by the gas pressure, so clamp tonnage requirements may drop by 30% or more. Lower clamp forces may mean extended mold life, adds Pearson.

External gas molding is a low-pressure process, requiring only up to 2000 psi of pressure to squeeze out sink marks, even in thin-wall applications. An internal gas process may require two to three times that amount (approx. 1000 to 3700 psi), and conventional injection molding uses even higher pressure (approx. 4400 to 10,000 psi) without necessarily solving the problem, says Pearson.

External gas also can assist with part ejection from the core, minimizing or eliminating ejector marks. It can allow thinner part walls for lower material usage. Lower clamp pressures and elimination of overpacking help produce stress-free parts. Thinner walls and improved material contact with the mold can also lead to faster cooling and shorter overall cycle times.

“The use of an external gas system gives the molder an opportunity to use lower-cost, higher-shrink materials such as PP,” says CGI’s Pearson.

Other methods’ limitations

Suppliers of external gas techniques are intimately acquainted with internal gas-assist molding. Incoe has sold mold components for successful gas-assist jobs, and both Battenfeld and CGI market both internal and external gas processes. So their views of the limitations of internal gas assist are presumably unbiased.

“With internal gas molding, gas follows the path of least resistance, and therein lie potential problems,” says Incoe’s Blundy. “If the mold is hotter or cooler in one section, it can cause the gas channel to spread or branch into smaller channels, creating a fingering effect.” Fingering is not the only gas-assist phenomenon that can disrupt surface quality, adds CGI’s Pearson. Any hesitation in the flow of gas through the part can produce visible lines on the surface, similar to blemishes caused by hesitation in melt filling. Internal gas assist can also leave a “shadow” mark on the part at the point of gas injection, where the gas pressure is highest. As gas pressure drops farther away from the gas inlet, indentations or weld lines can result. Internal gas molding also requires an entry and exit hole that remain as a blemish on the part. (One internal gas system, from Hettinga Equipment, keeps the gas in the part after molding.)

Pearson adds that it is a challenge to get internal gas to flow down into a rib. “If you have a lot of parallel ribs, it is virtually impossible to get the gas to flow uniformly down each rib.” Family tools with dissimilar cavities can also present problems of satisfactory gas penetration with internal gas assist, he notes.

Internal gas injection also requires special gas-delivery nozzles and venting devices, as well as spillover valves for the melt displaced by the gas. These items are eliminated or re-engineered into the mold with external gas.

External gas molding holds process advantages over conventional injection molding, as well. “Conventional molding tries to solve the problem of sink by high-pressure pack and hold. To offset shrinkage, conventional molders inject more material in the cavity for packing, but that creates stress within the part, and may not fully solve the issue of sink,” says Pearson. In some cases, molders will sustain the pack and hold time to prevent sink, at the expense of added cycle time.

To illustrate the advantages of external gas, Incoe molded a 100-in.2 scanner cover of ABS/PC alloy using a conventional process with and without packing, as well as its External Gas Molding (EGM) process. Cycle time was the same in all cases. The part made without packing weighed 246.5 g, required 41 tons of clamp force, and had sink marks. The part produced with the packing phase weighed 261.5 g, required 125 tons of clamping, and still had sinks. The EGM part weighed 246.5 g, needed only 41 tons of pressure, and was sink-free, Blundy reports.

No panacea

External gas technology is not a panacea for all molders, suppliers caution. “There are many molding jobs where a degree of stress in a part is acceptable and doesn’t have adverse effects on the product,” says Pearson.

Sources at CGI, Incoe, and Battenfeld also warn that external gas molding is limited to parts requiring a high-quality finish on only one side. External gas pressure can leave a wavy effect on the non-critical side of the part. “So a molder of clear parts may not want to use this process,” cautions Battenfeld’s Ehritt.

However, Textron technical-services manager Anthony Spalding says his firm is optimizing its process to minimize that effect. The firm has a made a blemish-free sample panel from clear ABS.

Some suppliers also say high-purity (at least 98%) nitrogen gas is the best for their process. Higher oxygen content in the pressurized gas can cause oxidation of some plastic melts. Using nitrogen adds equipment and/or operating costs. But Textron spokesmen say they have seen no problems with using compressed air in the IntelliMold counterpressure technique. Also, Incoe recently tested its EGM process with clean, dry shop compressed air and is encouraged by the initial results, Blundy reports.

Suppliers note that material and cycle-time savings will be partly offset by licensing fees, mold modifications, and additional equipment costs to run the process. Also, some sources concede that cycle-time reductions with external gas can be minimal. In order to be effective, there is typically a delay between cavity filling and introduction of the gas. “You must give the material a little time to set up, so that the gas has something to push against,” says Blundy. The time for the gas to enter, pack, and exit the tool is about the same as the pack and hold time of conventional injection.

Tooling modifications

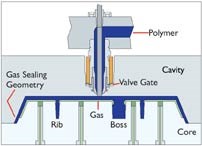

External gas injection typically requires a pressure sensor in the mold or in the gas-delivery lines, as well as a gas generator and control technology. The speed of gas injection is important, as well as the pressure. Mold modifications can add 5% to 20% to tool costs. The most critical aspect of tool modification is tight sealing of the mold to hold uniform gas pressure during molding. Critical areas for sealing are the parting lines, ejector pins, cores, and vent holes. In molds with moveable cores or other components, suppliers suggest adding a seal block to the outer part of the mold. Silicone rubber is the most commonly used seal material.

Part design also contributes to effective gas seals. “Part geometries near the parting line must be modified slightly to create the seal,” says Incoe’s Blundy. Often, a rib or boss in a part naturally cordons off the gas so that it acts on a local area between the ribs.

Evacuation of the gas also requires some mold modification. Textron connects the existing vents in a conventional mold by machining a single channel that acts as an air manifold. Other systems, like Incoe’s EGM, rely on a porous-metal insert in the mold that allows for the gas to enter and exit. “When the supply of gas is turned off, gas flow reverses back through the insert, following the path of least resistance,” says Blundy. In addition, special valve-gate technology may be needed to prevent the gas from escaping through hot-runner nozzles.

Three external gas methods

Battenfeld’s Airmould Contour process is an extension of its Airmould technique for internal gas assist. It uses a mobile gas-delivery unit with graphical touchscreen controls. “We don’t control the volume of gas into the part, we look at the pressure,” says Ehritt. The closed-loop gas-pressure control system introduces and maintains the gas pressure in the cavity on a time or melt-pressure trigger signal. Gas enters through a nozzle or needle that is designed to install flush with the inner cavity surface.

The process is installed on 500-ton and 4000-ton presses at the Auburn Hills, Mich., lab of Solvay Engineered Polymers. These presses are available to Battenfeld for customer demonstrations Licensing costs depend on the application.

Cinpres Gas Injection has licenses to two external gas technologies owned by Asahi. One is similar to that offered in North America by Incoe. The second covers external gas injection with the added packing function. “Even with external gas there may be some volumetric shrinkage. Packing helps minimize the shrinkage further,” says Pearson. He declined to say in what circumstances CGI would recommend one process over the other or to specify in detail how the two processes differ. Parts made on either process are indistinguishable from each other, according to Pearson.

CGI offers a nitrogen-injection system that delivers gas at pressures up to 1470 psi, controlled by sensors installed in the mold and machine.

CGI claims users of its process can reduce part wall thickness by as much as 50%, cycle times by up to 40%, and mold pressure by at least 25%.

The process can be licensed by the mold or by the press. The fee is typically from $5000 to $20,000, depending on the size of the mold and the equipment needed. The fee lasts for the life of the mold, and there are no ongoing royalties. CGI also provides a service to modify molds for external gas molding.

Incoe’s EGM process applies nitrogen at up to 1500 psi to the molten plastic in the cavity through the core side of the mold. Gas enters through a porous-metal insert, gas pin, or poppet. The gas controller requires a signal from the press to release the gas at or near the end of fill. That signal can be generated according to time or screw position.

Incoe charges a one-time fee of $5000 to $15,000 per mold for the use of EGM technology, based on the total projected area of the part. Incoe charges an additional $7500 to $9000 for gas-control equipment, although molders can use gas controllers from other suppliers. Incoe can demonstrate EGM at its lab on 125- and 425-ton presses.

Gas counterpressure

Textron’s IntelliMold external gas process differs from the others in two respects. First, it pre-charges the mold cavity with air before melt is introduced. Second, it continuously measures and controls the internal melt pressure as the cavity fills, with the goal of achieving uniform part density. The concept behind this technology is that in conventional injection molding, the melt initially encounters low pressure on entering the mold and then very high pressure at the end of fill. This is especially true when high packing pressures are used in an attempt to fight sinks. The difference in density between the first and last material to solidify is itself the source of sinks, stresses, and warpage, Textron says.

“We charge the mold with 200-psi shop air, which helps to control the flow front of the material and achieves uniform density from the beginning to the end of part fill,” explains Textron’s Spalding. “The counterpressure packs the part as we fill, so we do not need to overpack the mold or stress the material.”

The pressurized air acts as a constant force that pushes material uniformly against the walls of the cavity. “This achieves better dimensional stability and reduced warping, sinks, knit lines, and shrinkage,” Spalding says.

In addition, the force of the gas holds the appearance side of the part in contact with the mold-cavity surface longer by preventing it from shrinking away. This, along with the elimination of pack and hold, can trim cycle times by 25%, Textron claims.

The IntelliMold system uses two pressure transducers, one in the nozzle, and the other in the cavity at or near the farthest point of fill. As the melt enters the mold, the compressed air is forced back out the vents from which it entered. The cavity transducer senses the pressure of the gas initially, and then the melt pressure when the cavity is almost filled. A controller receives pressure data from the two sensors every 2 millisec and processes those data with proprietary algorithms to arrive at a nominal value for the melt pressure in the cavity. The controller adjusts the speed of the injection ram to maintain the setpoint value for in-mold melt pressure. That setpoint is selected by trial and error or previous experience with the process.

Setting up the IntelliMold process does not use a conventional injection-speed or pressure profile. There is no speed profile, and the pressure profile is essentially flat. This approach is said to make the injection process “transparent,” or immune, to variations in oil viscosity, mold and ambient temperatures, and material viscosity.

Textron conducts IntelliMold trials on four machines at its lab—Van Dorn 230- and 350-tonners, a 500-ton Engel, and an 880-ton HPM press. Textron licenses the technology on a per-machine basis. Cost is determined on a sliding scale based on press size. Installation and training are included in the license fee. Engel and Van Dorn Demag are licensed to offer the IntelliMold process on their machines.

Textron also offers two variations of its IntelliMold process: Xtralite for molding foamed products and Xtrasoft, a process for molding dual-durometer, hard/soft parts with a single barrel. Textron recently launched a website dedicated to the process, www.intellimold.com.

Related Content

Internal Gas Pressure Molding Offers Sustainability Benefits

Wittmann Battenfeld says its upgraded Airmould 4.0 technology, which features a more compact footprint, saves material and cycle time — thereby also cutting energy use.

Read MoreFakuma 2023: Wittmann Battenfeld Expands All-Electric Line, Direct-Current Capabilities

Wittmann Battenfeld will introduce the new EcoPower B8X injection molding machine line and show direct current as an energy source for a concept machine that will power its own robot.

Read MoreCompletely Connected Molding

NPE2024: Medical, inmold labeling, core-back molding and Industry 4.0 technologies on display at Shibaura’s booth.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read More