Extrusion & Injection Molding in One Automated Process

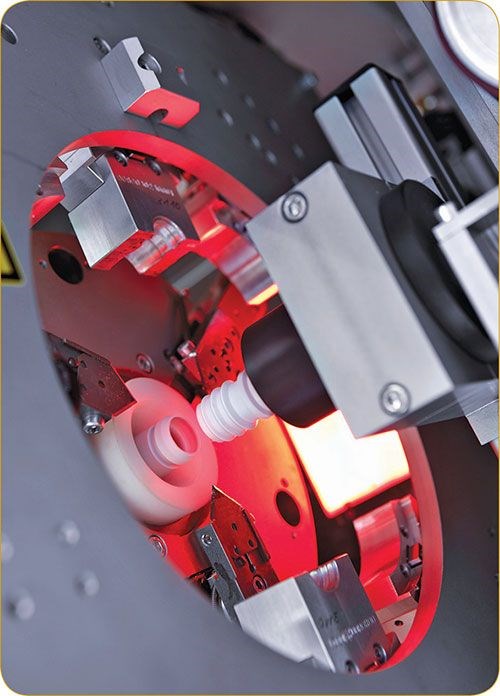

Close Up: Injection Molding

A large German manufacturer of hoses, cable ducts, and other extruded automotive components recently expanded its activities into the white-goods appliance sector.

A large German manufacturer of hoses, cable ducts, and other extruded automotive components recently expanded its activities into the white-goods appliance sector. Its largest project to date involves extruding corrugated hoses and molding fittings (with an inserted O-ring) onto both ends. The need was for high-volume production of high-quality but inexpensive hoses for Germany’s largest dishwasher manufacturer. “The ideal system is one where the plastic granulate is filled in at one end and ready-to-ship hoses come out at the other,” says Roland Meissner, division manager of Air & Fluid Systems at Schlemmer GmbH in Hassfurt. “This ensures consistently high quality around the clock. And compared with two-stage production, it saves the costs for intermediate storage.”

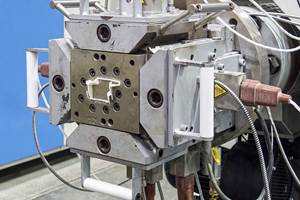

Achieving the ideal required combining extrusion and injection molding into a flexible, automated production cell. “Our first criterion when selecting a suitable supplier was a turnkey system, as we wanted everything from a single source,” says Meissner. Schlemmer found that source in Arburg GmbH (U.S. office in Newington, Conn., arburg.us). Arburg acted as general contractor and also supplied a 100-metric-ton Allrounder vertical-clamp insert-molding press. Other project partners were Straberger for the injection mold, FPT Robotik for automation, Ohrmann for O-ring placement, and Furness Controls for leak testing. The entire system was commissioned in only eight months.

HOW IT WORKS

A number of challenges had to be overcome. “The extruded PP hose material cannot be handled when cold, as so-called stress whitening occurs,” explains Schlemmer process technician Hubert Rausch. “However, the warm material shrinks by several centimeters during the production process, which must be compensated for by the three robotic systems during handling.” Moreover, about a dozen significant dimensions must be maintained on the hose body.

Schlemmer devised a technique using three blades to cut the hose to a precision of 0.1 mm. Off-spec parts are detected automatically by a photoelectric barrier. Good parts are picked up by a four-axis robotic system from Kuka Robotics (U.S. office in Clinton Township, Mich., kuka-robotics.com) and transferred to an O-ring placement station. This takes care of the most difficult task: precise positioning of six flexible hoses, each 2.25 meters long, for O-ring insertion.

Two synchronized FPT linear robots then grip the front and rear of the hoses. The linear robots handle 12 parts in a single operation. They remove six hoses with the molded-on TPE fittings and insert six new ones. The finished hoses are set down to cool in an intermediate station.

At the same time, the Allrounder press (Schlemmer’s first vertical machine) injects six fittings in a cycle time of about 30 sec. “Despite the progressive shrinkage, a perfect join must be created between the hose body and fitting, without any over- or under-injection,” notes Rausch. “In this respect, Arburg and the mold manufacturer have contributed a lot of expertise. We’re currently working on speeding up extrusion while also further reducing the injection molding cycle time.”

The linear robots then transfer the cooled hoses to the next station for leak testing. Rejects are again removed and the other hoses are bundled into batches of 50. Six hoses pass through the entire cell in about 35 sec.

This system has been in production since early this year. To make this complex system easier to use, the robots use the same Selogica user interface as the Arburg injection machine. The two linear robots have a single controller, which is networked with the four-axis robot.

Related Content

Tight-Tolerance Molder Dips Toe in Extrusion Waters

Midwest Precision Molding brings extrusion capacity in-house to assist a customer that was having a sourcing issue with its existing overseas suppliers.

Read MoreMedical Tubing: Use Simulation to Troubleshoot, Optimize Processing & Dies

Extrusion simulations can be useful in anticipating issues and running “what-if” scenarios to size extruders and design dies for extrusion projects. It should be used at early stages of any project to avoid trial and error and remaking tooling.

Read MoreCrosshead Die for Elastomers Adjusts Easily

NPE2024: Mechanically actuated gum space adjustment requires only ordinary socket wrench.

Read MoreIs Your Die Flow Changing Despite Following All the Correct Formulas?

Maybe the problem is that you're starting up with a dry die. Here are tips to solve this issue.

Read MoreRead Next

For PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More