Five-Layer Line Gives Processor More Flexibility, New Opportunities

Processor bumps it up from three-layers to boost quality, flexibility and enter new markets.

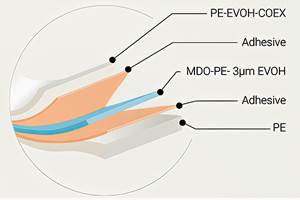

In blown film, material and equipment suppliers have been touting the benefits of five-layer structures over three layers in non-barrier applications for some time. In fact, it was a big theme at last October’s K 2013 show. At least one film producer has been listening.

BJK Flexible Packaging, Louisville, Ky., announced recently that it had installed its first five-layer blown film line in a new 30,000 ft² addition built specifically for that purpose. The company now has six blown film lines, with the other five of the three-layer variety. It plans on adding a second five-layer line this year, as well as another 30,000 ft² for production and warehousing.

The new line, which started running in November, will allow BJK to produce structures that will offer a better, more sophisticated alternative to three-layer films, according to Brian Krein, chairman and CEO. The 110-in.-wide line, furnished by Reifenhauser Inc., Wichita, Kan., is equipped with a 550-mm die and is capable of outputs to 1500 lb/hr. States Krein, “It’s our feeling that three-layer’s future for many film segments will move to five layers. These films allow more flexibility to extrude for specific applications.”

In business for more than 35 years, BJK is a major player in the poultry industry, providing films engineered to extend the shelf life of fresh chicken. A family-owned and operated company, it employs about 70 people and runs 24/7. “We knew the new line would be used to better serve our current customer base—for instance, to provide better films for the poultry industry to package fresh products in vertical form-and-fill bags,” says Jim Schandle, BJK president and COO. “Taking this technology to that industry and providing them with better products is huge for us. But we also plan to continue to diversify into other converting, laminating, and print markets.” Company executives would not be more specific about this diversification strategy, but did note that it is already running trials for new applications.

NOVEL FILM FLATTENER

On the equipment side, BJK officials say what swung its decision in Reifenhauser’s favor were that supplier’s Evolution Ultra Cool high-output air ring and its Ultra Flat film-flattening technology. The Ultra Flat is unique because, instead of being situated in front of the winder like other devices of its kind, it’s installed between the haul-off nip-roll assembly and turner-bar system, which Reifenhauser says is an ideal place for stretching and flattening because the film is still warm and more malleable.

BJK is the first North American film processor to use Ultra Flat Technology, states Steve DeSpain, president of Reifenhauser’s U.S. operation. “We feel strongly that Ultra Flat is a game-changing technology in blown film, and after visiting our plant in Troisdorf, Germany, for materials trials and seeing it for themselves, BJK felt that same way,” he says. “They said they wanted a differentiating technology to give them a competitive advantage, and this is it.”

Adds BJK’s Schandle, “The bottom line is that this technology will allow us to produce better quality films at higher speeds; and using five-layers gives us the ability to provide something new that the marketplace has not seen before."

Related Content

First Water Bottles With Ultrathin Glass Coating

Long used for sensitive juices and carbonated soft drinks, KHS Freshsafe PET Plasmax vapor-deposited glass coating is now providing freshness and flavor protection for PET mineral water bottles.

Read MoreMultilayer Solutions to Challenges in Blow Molding with PCR

For extrusion blow molders, challenges of price and availability of postconsumer recycled resins can be addressed with a variety of multilayer technologies, which also offer solutions to issues with color, processability, mechanical properties and chemical migration in PCR materials.

Read MoreHow to Extrusion Blow Mold PHA/PLA Blends

You need to pay attention to the inherent characteristics of biopolymers PHA/PLA materials when setting process parameters to realize better and more consistent outcomes.

Read MoreRecycling Terminology Can Be a Minefield, So We Should Tread Lightly

Loose propagation of terms like “recyclable” and “compostable” has already brought down government regulations on labeling. The plastics and packaging industries should take that to heart with other recycle-related language. Like “monomaterial” for example.

Read MoreRead Next

Reifenhauser to Unwrap New Extruder, Other Innovations

New machine and novel approaches in blown/cast film, sheet, and wood composites touted.

Read MoreExxon to Film Processors: Go With Five Layers

For a company that did not exhibit at K 2013, ExxonMobil Chemical certainly was busy at October’s Dusseldorf trade show. Material from the Houston-based resin giant was running on a handful of film lines producing everything from five-layer collation-shrink blown film to five-layer hygiene film, three-layer lamination film, and 33-layer nano-cast stretch film.

Read More