Frequently Asked Questions About Purging

Purging Tips: Part 3

This 'FAQ' sections answers common questions about how to choose and use purging agents.

Q: Why should we use a purging compound?

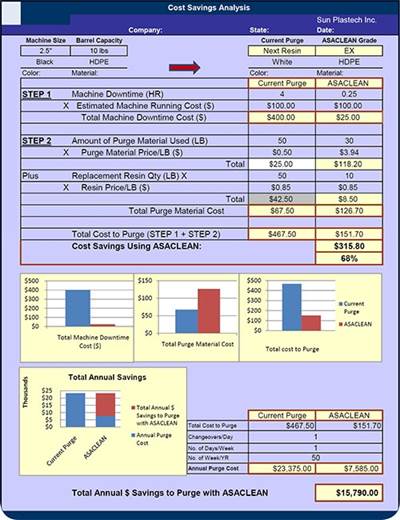

A: Antiquated methods such as flushing the machine with the next resin or using regrind are time-consuming, material-wasting, and just plain ineffective in removing color and carbon contamination. A high-performance purging compound such as Asaclean is designed not only to facilitate color and material changeovers, but to clean the machine as well.

Q: Why should we use purging compound when we have all this “free ” regrind ?

A: Regrind isn’t completely “free”—there are costs associated with using regrind. Aside from the energy cost for grinding, the greater cost lies in the ineffectiveness of regrind to purge and clean a machine. It is likely that a machine will have to be purged for a considerable amount of time with regrind, and then also purged several times subsequently during production. Clearly this offers no savings over using an effective commercial purging compound.

Q: We can ’t have any foreign debris or residue in our finished products . How can we ensure that my purging compound doesn’t leave an y residue behind?

A: It’s important to choose a purging compound that’s specifically designed to be a low-residue material, making it suitable for most purging applications. For especially residue-sensitive materials such as clear or soft materials, some purging compounds come in specialized grades to ensure even less residue being left behind. Lastly, following proper purging (especially purge displacement procedures) will ensure that the least amount of purging compound residue is left behind.

Q: We are conce rned about running abrasive materials through our machines . Are your glass-filled purging grades abrasive and could the y ca use any damage?

A: While this is a legitimate concern, all Asaclean grades are designed for maximum cleaning and minimal residue while being safe for the machines’ surfaces. Our glass-filled grades have high-scrubbing power yet are minimally abrasive. Because the residence time within the barrel is so short when purging with a glass-filled grade, there is virtually no wear and tear to the screw and barrel. The only cases in which glass-filled grades may not always be recommended is for purging hot runners or any equipment that may be highly polished or textured (such as extrusion dies), or have high-precision clearances (like extrusion gear pumps).

Q: In our experience with purging compound, it didn’t work sufficient ly for our needs.

A: There are various factors that could have led to a bad experience: Did you follow the purging procedures exactly as they were recommended? Sometimes a purging compound supplier may specially tailor their procedures to accommodate the purging scenario at hand.

•Did you used a sufficient quantity of the purge? Using even a little short of an adequate amount of purge can mean the difference between completely clean and almost clean.

•Was the purging compound you used appropriate for the application you tested it on? There are various types of purging compounds, including mechanical and chemical-type purges. Sometimes one type of purge may excel over the other, depending on the specific application. Even if one type or brand of purging compound didn’t meet your expectations, there is likely to be one out there that will. Virtually all purging compound suppliers offer free samples; it’s highly recommend that you sample different purges until you find the one that’s right for your needs.

•Perhaps a different grade or even a stronger grade of the purge you tested may be necessary. Always ask the supplier for alternative options.

Related Content

Purgex Purging Compounds Celebrates Founder's Induction to Plastics Hall of Fame and Holds Technical Seminars

NPE2024: Purgex team hosting technical seminars throughout the show with industry pros.

Read MoreReduce Downtime and Scrap in the Blown Film Industry

The blown film sector now benefits from a tailored solution developed by Chem-Trend to preserve integrity of the bubble.

Read MoreHow to Start a Hot-Runner Mold That Has No Tip Insulators

Here's a method to assist with efficient dark-to-light color changes on hot-runner systems that are hot-tipped.

Read MoreThe Power of Self-Emptying Technology for Extrusion Lines

Advanced purging compounds can save you time, frustration, and cost.

Read MoreRead Next

How to Use Commercial Purging Compounds in Extrusion

CPCs are considered most often for injection molding. However, they also can provide the same benefits to extrusion processors.

Read MoreTips and Techniques: Break the Taboo On Purging Hot Runners!

It’s safe to say that the concept of using a commercial purging compound (CPC) has largely been embraced by the plastics processing community.

Read More