New Injection Machine Safety Standards in MI Could Have National Consequences

In a bid to have the state’s safety guidelines better reflect the national standard, the Michigan Occupational Safety and Health Administration (MIOSHA) has adopted new machine safety guidelines that have sparked more questions than answers for molders and machinery suppliers.

Effective Jan. 1, 2017 operators of horizontal injection molding machines in Michigan will be required to comply with full lockout/tagout (LO/TO) requirements if there is the potential for harmful exposure to hazardous energy sources during maintenance and servicing activities.

Previously, mold changes through either the front or rear gate of a horizontal injection molding machine were allowed as long as the machine had a functional mechanical safety plus two independent interlocks on the operator’s gate, as well as an emergency or other stop that would shut off the motors that activate the clamp.

MIOSHA has now changed the rule—Part 62 Plastic Molding Safety Standard R408.16234—so that it meets OSHA’s General Industry Safety Standard Part 85 “The Control of Hazardous Energy Sources”. Specifically, starting in the new year, molders are instructed to phase out procedures that allow for either the front or rear gates of a horizontal press to be locked in the open position during mold changes. MIOSHA has recognized that the Part 85 Lockout standard might not be possible on some machines without shutting down a press’s heating system.

MIOSHA has stated that there are exceptions to the LO/TO requirements. Specifically, these include maintaining or servicing presses if there is machine guarding that’s deemed capable of eliminating exposure to “hazardous energy.”

David Palmer, SPI’s director of industry affairs—equipment council, noted that MIOSHA deems routine mold or die changes to be maintenance and servicing activity. According to OSHA CPL 02-00-147, setting up is “any work performed to prepare a machine or equipment to perform its normal production operation.” Setting up is not considered utilization of a machine or equipment and is classified as servicing and/or maintenance, rather than normal production operations.

Minor services, in the eyes of MIOSHA, would include things like lubricating, cleaning or un-jamming equipment. Barrels and hot runner manifolds would also be considered a hazardous energy source requiring personal protective equipment and signage.

Machinery suppliers have pointed out to MIOSHA that during a tool change molders want to maintain heat and have access to a powered-up control, and the agency has recognized that, noting that “it would be allowable to use a separate energy isolating device that can be locked out during the die changing process for a motor, pump or other equipment…while leaving power on to the heating elements and computer controls.”

Industry Response

SPI: The Plastics Industry Trade Association held a meeting in Chicago on August 3 with members to discuss the rule change, with a follow up conference call on Nov. 17. In an email, Palmer noted that the association had been working directly with MIOSHA to reverse the changes to Part 62. It has also reached out to Michigan molders asking for information it could use to lobby on their behalf.

MIOSHA noted in an Oct. 3 email from the Michigan Department of Licensing and Regulatory Affairs that it had mailed letters to approximately 1000 companies in the state classified under the NAICS 326 code (Plastics and Rubber Manufacturing) giving notice of the change.

MIOSHA’s Consultation Education and Training (CET) Division also scheduled six information sessions to “ensure awareness of the updated standard and answer any questions employers may have.” Held from mid-October through December 7, these sessions took place in Canton, Kentwood, and Lansing, Mich. At the time the email was sent, the sessions on Oct. 18 and Nov. 1, held in Canton and Kentwood, respectively, where completely booked, while a Dec. 7 event in Lansing only had three seats left.

A question in the email announcing the sessions reflected how potentially sweeping the changes could be, asking:

“Could this change affect you? It might if you have horizontal plastic injection mold machines and perform mold changes.”

Related Content

Injection Compression Molding as Alternative to Thermoforming

Arburg will show its all-electric Allrounder 720 A press utilizing injection compression molding to create thin-wall IML cups from PP.

Read MoreCustom Injection Molder Plugs into All Electric Machines

Formerly a showroom for early-aughts-era Van Dorn hydraulics, the newest additions to Drummond Industries’ transforming fleet are all-electric Niigata injection molding machines.

Read MoreAll-Electric Injection Molding Machine Line Expands

Fakuma 2024: Engel unveils new e-mac 500 with “High” clamping drive and encapsulated toggle-lever mechanism.

Read MoreCompact Hybrid Injection Molding Machine Launched

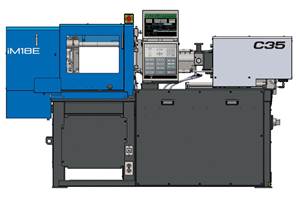

Sumitomo Heavy Industries Ltd. (SHI) has introduced the iM18E, promising the smallest footprint in 20-ton machines.

Read MoreRead Next

Beyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More