Important Factors and Approaches to Estimating Residence Time in Injection Molding

Residence time can have a dramatic impact on part quality and production efficiency but determining its value can be tricky. Use these methods and formulas to accurately measure residence time and enable it to inform everything from scheduling jobs to optimizing a process.

Residence time can be impacted by increasing or decreasing the amount of material the machine processes per hour or if the injection unit specifications have changed, which is common when moving molds among machines. The residence time is defined as the time a resin pellet is physically in the barrel and exposed to shearing or heating via conduction. Changing any time-related machine parameter — cooling time, packing time, holding time, mold open/close times, mold protection time, part ejection time and the addition or removal of a robot — will change the residence time.

This information is crucial, as it will be used to schedule molds for specific machines, determine the optimal placement for thermally sensitive materials to minimize residence time, or assist a custom molder in purchasing a new machine and specifying the appropriate barrel size for a variety of materials and part weights.

As a plastics engineer, I often find that some of the simplest questions in our field can be the most challenging to answer. One such question is determining how many shots of plastic are present in the barrel and calculating the corresponding residence time. A commonly accepted target for residence time in the industry is between 2 to 5 minutes. However, this rule of thumb may not be applicable when working with high-temperature engineering thermoplastics, such as PEEK or thermally sensitive materials like PBT or PVC. Additionally, when PP and PE are applied in packaging applications, deviations from this guideline may also occur.

Throughout my career, I have observed that residence times for packaging applications utilizing RS machines can at times fall below 1.5 minutes. This duration is typically inadequate for effectively elevating semicrystalline plastics to their optimal processing temperatures. In certain instances, increasing the barrel temperatures by 100°F to 200°F has been employed to enhance heat transfer through conduction, compensating for insufficient shear generated by the screw configuration. Although solutions such as implementing barrier screws; utilizing screws with higher L/D ratios and increased compression ratios; or acquiring machines specifically engineered for packaging applications may address these challenges, they often present impracticalities regarding cost and machine capacity constraints.

I have also seen residence times as high as 15 minutes for thermally sensitive materials running in semiautomatic mode. In this case, no matter how much we attempted to lower the actual plastic temperature, we had to intermittently purge the barrel to remove degraded material.

The most straight forward method to assess residence time for an existing running application is to note the maximum machine shot size, actual shot size and cycle time, and with those figures calculate the residence time using the following equation:

In determining your actual shot size, the cushion and amount of postdecompression should be removed to determine the actual amount of plastic displaced. For example, on a machine that has a maximum shot size of 12 inches with 1.5 inches of plastic being displaced that’s running in a 15-second cycle time, the residence time would be 2 minutes.

However, if we consider that true residence time is defined as the time a pellet is physically in the barrel, the above calculation omits the amount of plastic that is being conveyed down the length of the screw within the metering, compression and feed zones as illustrated in Figure 1.

When determining residence time, molders should consider the different zones of a general-purpose screw. Source: Orbital Consulting

Determining this involves pulling back the hopper or shot loader and noting when pellets are last seen between the screw flights in the feed zone and then allowing the machine to continue to cycle. (Important: DO NOT look down the feed throat but rather use a mirror and apply full PPE to avoid being burned by any hot plastic that could be discharged from the feed throat).

For example, you count five complete shots in automatic mode over a 30-second cycle with a 2-inch shot of actual displaced plastic, but on the sixth shot, the screw only recovered to a calculated 1.5 inches of actual displaced plastic, you can then calculate: 1.5 ÷ 2.0 = 0.75 inch, or three-quarters of a shot. In this case, you would add three-quarters of a shot to the fifth shot, resulting in a total of 5.75 shots. The residence time can then be calculated by multiplying the total number of shots with the cycle time: 5.75 shots × 30 seconds equals a residence time of 172.5 seconds (or 2.9 minutes).

Another method would be to add a colored pellet of the same material or a pellet from a batch of color concentrate into the machine and note the moment pellets are last seen between the screw flights in the feed zone by moving the hopper or shot loader back over the feed throat and noting when parts are first molded with color. Of course, if you are running black material, this could be an issue.

John Bozzelli discussed this method in an article titled, “A Simpler Way to Calculate Shot Size vs. Barrel Capacity,” first published in February 2017 and updated in June 2022. He puts forward other limiting factors, such as using the above method for an existing application in production and actually calculating the residence time for a machine purchase.

Bozzelli also points out a common error in calculating the barrel capacity — confusing melt density with specific gravity. The barrel is commonly specified in ounces or grams of general-purpose PS or at times PE. A common misconception is that parts can be produced with any material at the specified barrel capacity. We must convert the barrel size to accurately reflect the material that we are molding, whether it be more or less dense than GPPS, by using melt density versus specific gravity. This will result in the following equation:

For example, we are interested in running PC with an L/D ratio of 22:1 and a 60-ounce barrel, where the melt density of GPPS is 0.97 g/cm3 and 1.02 g/cm3 for PC. This would yield a barrel capacity of approximately 63.1 ounces of PC.

Conversely, if a less dense material is molded — such as PP with a melt density of 0.75 g/cm3 — this yields a barrel capable of processing approximately 46.4 ounces of PP.

Because PP is less dense than GPPS, if a scheduler or someone providing quotes assumes that 60 ounces of PP can be processed, they’ll find the actual amount is only 46.4 ounces. This misconception leads to an inaccurate calculation of the barrel’s utilization percentage, which can affect the expected residence time. In some cases, this can result in the maximum machine shot size being inadequate to fill and pack the machine and mold combination, which results in short shots or the need for the molder to utilize intrusion to compensate.

As mentioned earlier, to achieve a more accurate residence time, it’s also important to account for the material being plasticized in the screw’s feed, compression and metering zones. A method I’ve been using comes from a guide published by Spirex, titled “Plasticating Essentials.” Originally authored by Paul and Illene Colby in 1979, the guide has been updated with additional information in versions released in 1985, 1992 and 2000.

Within this guide, they propose a barrel factor based on the work of Bernie A. Olmstead and Martin E. Davis in which a factor of 1.4 is used to calculate the residence time if the machine injection stroke is four diameters or more. If the machine screw stroke is three diameters, the multiplication factor is 2.0. This assumes the screw has a 20:1 L/D ratio with general purpose compression factors and flight depths.

Thus, Equation 1 is modified with a barrel factor of either 1.4 or 2.0 to yield Equation 3.

Barrel factors based on bore diameters. Source: Practical Injection Molding, Olmstead and Davis

As with Example 1, in calculating the residence time, we would either have 2 minutes x 1.4 or 2 minutes x 2.0 to yield a residence time of either 2.8 or 4.0 minutes, depending on the machine injection stroke and its screw diameter.

I have used a barrel factor of 1.4 throughout the bulk of my career with good results. What I did not consider is the source of these barrel factors. In reviewing Olmstead’s and Davis’ data in their book, “Practical Injection Molding,” they developed a barrel factor based on the bore diameter of the barrel which is cited below in Table 1.

In order to use this data, we must first calculate what is called Screw Inventory (SI) which considers a L/D ratio other than 20:1 and utilize a barrel factor from Figure 2. The equations are as follows for Screw Inventory and Residence Time:

Where:

Thus, for a machine with a 60-ounce barrel, bore diameter of 75 mm (1.30 factor from Figure 2), L/D ratio of 22:1 running 23 ounces of PC, at a cycle time of 30 seconds our screw inventory and residence time is as follows:

Comparing the screw inventory of 90.2 ounces versus the previous calculated screw inventory of 63.1 ounces of PC (see example 2), the barrel capacity is increased by 27.1 ounces of PC. An increase of nearly 43%, this will clearly affect the residence time for this example.

If one chooses to calculate the residence time based on the maximum machine shot size or to include the amount of plastic that is between the screw flights, multiple residence times can be calculated. In my humble opinion, Equations 4 & 5 put forward by Olmstead and Davis provide an alternate calculation considering a different L/D ratio along with the bore diameter of the barrel.

Additionally, using specific gravity to convert barrel capacities for different materials is often a mistaken approach that assumes the injection unit is rated in grams or ounces of GPPS and that rating applies to all materials molded on a machine.

ABOUT THE AUTHOR: Umbert Catignani is president of Orbital Plastics Consulting Inc., a consulting firm that has more than 100 years of combined experience in scientific injection molding, training, material selection, part design review, in-mold instrumentation, project management and equipment selection. Umberto is a past president of the Southern Section of SPE and has more than 29 years of hands-on injection molding experience. He has certified and trained hundreds of plastic professionals in the industry and has served as an expert witness. Past employers include IBM, General Motors, Delphi Automotive and Husky Injection Molding Systems. Catignani earned a master’s degree in polymer engineering from The University of Akron and a bachelor’s degree in materials engineering from the University of Cincinnati. Contact: 404-849-6714; umberto@orbitalplastics.com

Related Content

A Systematic Approach to Process Development

The path to a no-baby-sitting injection molding process is paved with data and can be found by following certain steps.

Read MoreBack to Basics on Mold Venting (Part 1)

Here’s what you need to know to improve the quality of your parts and to protect your molds.

Read MoreBack to Basics on Mold Venting (Part 2: Shape, Dimensions, Details)

Here’s how to get the most out of your stationary mold vents.

Read MoreUnderstanding Melting in Single-Screw Extruders

You can better visualize the melting process by “flipping” the observation point so the barrel appears to be turning clockwise around a stationary screw.

Read MoreRead Next

LS Mtron and Orbital Plastics Consulting Partner on Injection Molding Training

The machine supplier and plastics consultancy will provide hands-on courses taught by Orbital’s Umberto Catignani that take place at LS Mtron’s Technical Center near Chicago.

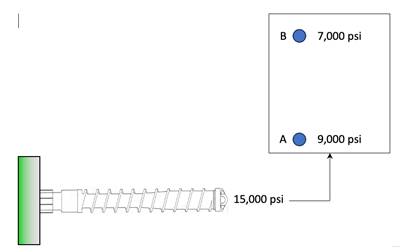

Read MoreUnderstanding the Effect of Pressure Losses on Injection Molded Parts

The compressibility of plastics as a class of materials means the pressure punched into the machine control and the pressure the melt experiences at the end of fill within the mold will be very different. What does this difference mean for process consistency and part quality?

Read MoreUse These 7 Parameters to Unravel the Melt Temperature Mystery

Despite its integral role in a stable process and consistent parts, true melt temperature in injection molding can be an enigma. Learning more about these seven parameters may help you solve the puzzle.

Read More