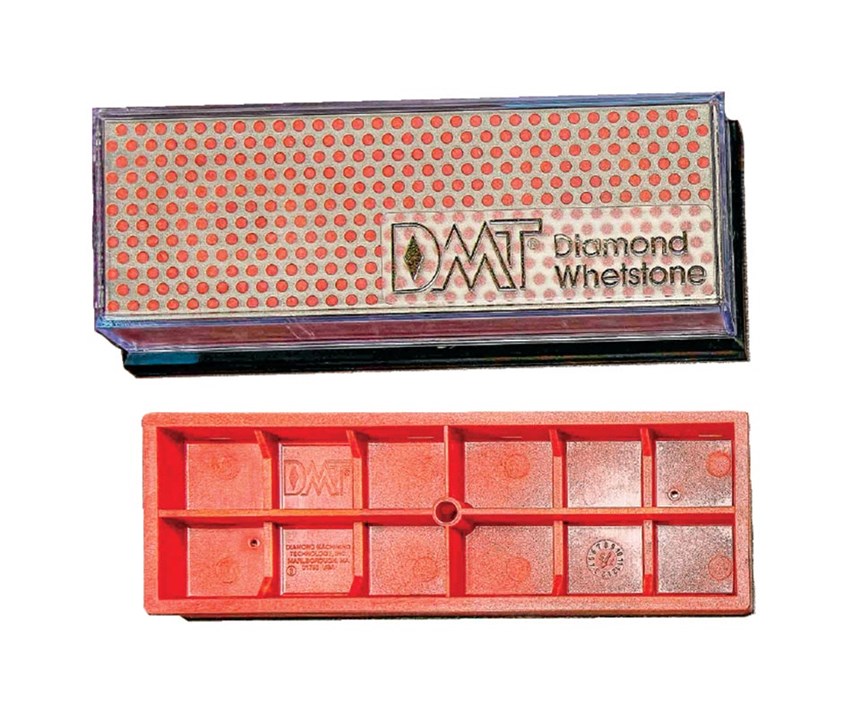

“If it’s got an edge, we’ll sharpen it.” That, in a nutshell, is the business model of Diamond Machining Technology (DMT), a division of Acme United Corp. The company considers itself the quality and technology leader in diamond sharpening tools for knives, scissors, woodworking implements, wire cutters, skis, ice skates, snowboards, and any other metal object that requires a sharp edge. Its sharpening “stones” are, in most cases, precise metal sheets of metal with electroplated nickel and diamond particles of various sizes. These metal sheets are insert molded onto polycarbonate bases.

In 1985, when injection molding replaced laminating of the metal grinding surfaces onto plastic, DMT gained a major increase in quality and productivity. In the past year, DMT honed its injection molding technology to a finer edge with the purchase of a new machine, robot and auxiliary equipment in a cell that embodies key elements of Industry 4.0.

The age of “Smart Factories,” or Industry 4.0, is still in its infancy. Many of the essential building blocks—standard communication interfaces between “smart machines”—are still being developed. At May’s NPE2018 show, numerous equipment vendors showed North American processors the steps being taken on what will no doubt be a long path forward. DMT has taken some of those steps itself, becoming a pioneer among U.S. processors—all the more remarkable for a shop with only three injection machines—and has experienced significant benefits in uptime, efficiency, troubleshooting, and faster product changeovers.

JOINING ‘TEAM EDGE’

DMT is a 40-year-old business that got a shot in the arm when it was purchased by Acme United Corp. in 2016. Based in Fairfield, Conn., Acme is a $140-million global company with over 400 employees. Among its diversified businesses are several brands of knives, scissors, shears, axes, and other cutting implements. DMT, therefore, was a logical addition to Acme’s “Team Edge” group of companies.

Located in a 28,000-ft2 plant in Marlborough, Mass., DMT employs 25 to 30 people in metal stamping, electroplating, and finishing the metal sharpening surfaces, as well as injection molding and packaging. It molds glass-filled polycarbonate for the ribbed backing of the metal sharpening plates, and black ABS for the holder of a double-sided sharpener. DMT also molds some products with talk-filled PP.

As explained by Mark Bettke, senior director of operations and manufacturing, flatness of the sharpening surface is a key quality spec, which is why DMT uses glass-filled PC for its hardness and stiffness. “Our flatness spec is ±0.001 in. over the entire surface, which can be up to 40 in.2 on a large, double-sided stone. Our sharpeners are the flattest in the world.”

“And to get that requires very consistent shot size, packing, and process temperatures,” adds Stan Watson, technical director and a 31-year veteran at DMT. With a high glass content and thick walls (about 0.140 in.) in the ribbed backing structure, we don’t make it easy for ourselves.”

The need for molding precision and consistency accounts for DMT’s preference for all-electric molding machines, going back to its second machine purchase 18 years ago. Besides being more precise, Watson credits electric machines with lower energy consumption and discharging less heat into the plant air.

After the acquisition, Acme United urged DMT to update its injection machines, which were then 16 and 31 years old. The first step was several months of research into machines and vendors by DMT personnel. “We visited four machine builders,” Watson recalls. “We looked into everything, including maintenance, parts and service. We also talked to our outside vendor of plastic parts about how it felt about its equipment.

“The more we researched, the more we became interested in Wittmann Battenfeld, because they could supply the whole system, with machine, robot, and auxiliary equipment.” DMT was impressed particularly by Wittmann’s expertise in robot end-of-arm tooling (EOAT) and its Wittmann 4.0 program for networking all its equipment together to share data and integrate the various controls. “We immediately saw the value of having all the equipment talk to each other—how could we pass that up?”

DMT personnel made multiple visits to Wittmann Battenfeld’s U.S. headquarters in Torrington, Conn. (wittman-group.com), including three days of training on use of the machine and robot. DMT visited another Wittmann customer to gain further insight, and Wittmann offered other customer contacts as well.

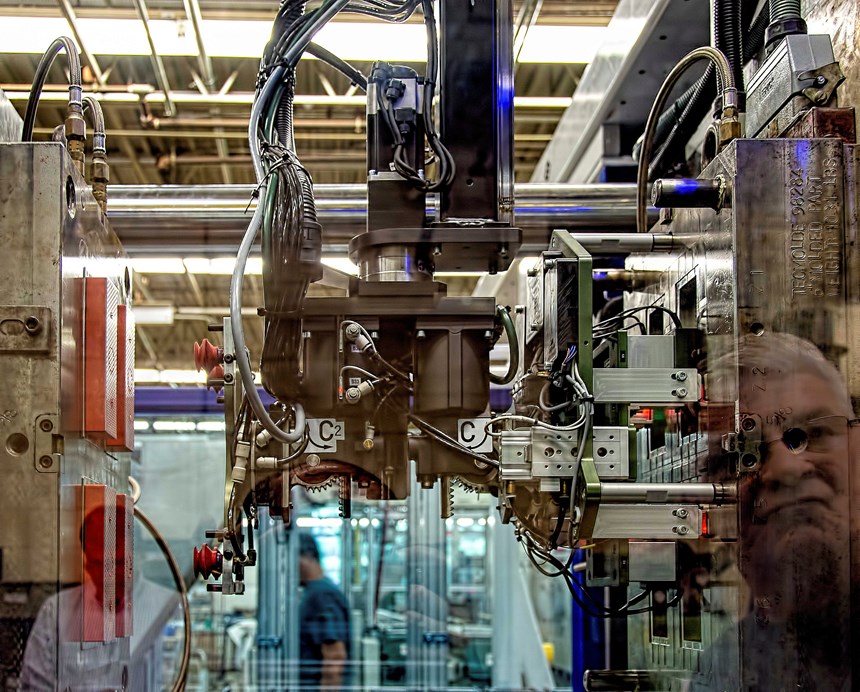

Finally, with the installation last August of an EcoPower 330-ton all-electric press, W-833 Cartesian robot, chiller, TCU, dryer, blender, and hopper loader, DMT became the first U.S. company to install a Wittmann 4.0 system using the company’s latest Unilog B8 injection machine control as the hub for integrating the cell components. Wittmann Battenfeld has over 30 U.S. customers using various elements of Wittmann 4.0, but DMT is the first with the very latest technology.

IMPLEMENTING 4.0

Like most molders to date, DMT has implemented just some parts of the overall Wittmann 4.0 ecosystem. One is the integration of data and settings for the robot, blender, and TCU with the Unilog B8 press control. Bob Parkhurst, DMT’s maintenance manager, likes the large B8 touchscreen, which Wittmann Battenfeld customized for his firm. It shows on one screen all barrel and hot-runner temperatures, cooling time, pack/hold settings, blender settings, and TCU temperatures.

Parkhurst likes that he can now see key process data on one screen and not have to walk round the cell to examine screens on the robot, blender, or TCU. (The central chiller and dryer, which supply all three injection presses, are not integrated with the Unilog B8 control.) He can also see data and modify settings on all the cell components from a computer in his office.

Also valuable is the ability to load the setups for the machine, robot, blender, and TCU together as one recipe when a mold is changed, which happens up to three times a week. That saves considerable time, Parkhurst says.

Overall, Watson adds, “The Wittmann 4.0 system makes me feel more secure. If something goes wrong, I’ll know it right away. For instance, if the TCU is running at 180 F instead of 220 F, the machine controller will flag that right away. In the past, we might have made a few hundred reject parts before we noticed that. Or if the TCU springs a leak and loses pressure, that flashes on the screen of the injection machine. Before, we wouldn’t have known it was happening until we saw the water on the floor.”

Watson and Parkhurst also appreciate the ability to have the TCU automatically suck the water out of the mold as part of a shutdown for a mold change. “That way, we don’t forget to empty the water from the mold and have a mess on the floor when we unplug the cooling hoses,” Watson explains.

Another element of Wittmann 4.0 is remote service capability. “We can let Wittmann Battenfeld remotely access our machine and find what is causing a problem, instead of waiting for a technician to come visit us,” says Watson. “They can diagnose the issue in minutes rather than us losing a day.”

Parkhurst notes that this came in handy twice already. In one case, the machine was programmed to stop for a regular maintenance cycle. “We didn’t know it was due, so we weren’t sure why the machine had stopped. But Wittmann Battenfeld was able to find the cause immediately. After performing the maintenance, were quickly back up and running.”

In another case, Parkhurst recalls, a safety switch caused the machine to stop. Again, Wittmann service personnel were able to look at the controller remotely and find the problem in a minute. “We made an adjustment to get the machine operating again, and we were back up in less than an hour. Wittmann sent us a replacement part, which arrived the next day.”

Bettke says DMT’s maintenance staff is starting to use Wittmann Battenfeld’s QuickLook app on their mobile phones, which provides another level of connectivity and convenience by showing cycle time, number of parts produced, machine status, alarms, and more.

ROBOTS WORK FASTER & SMARTER

Wittmann Battenfeld’s ability to supply complete systems has proven especially valuable to DMT in the case of robots. “We get better support there than from other vendors. When we came to Wittmann, they were very keen to shave off cycle time with more efficient robot programming and more capable EOAT,” says Watson.

He notes, for example, that in the past, loading two inserts for a double-sided sharpener into each side of the mold and removing a finished part required multiple robot entries and exits from the mold area. Wittmann Battenfeld designed three-headed EOAT that places both inserts and removes the finished part in one in/out cycle. The net result was reducing the mold-open time from 85 sec to just 10 sec.

Watson cites other cases where the new Wittmann robot and EOAT drastically reduced mold-open time:

- From 83 sec to 14 sec;

- From 58 sec to 12 sec;

- From 51 sec to 10 sec;

- From 39 sec to 8 sec.

Apart from the time savings, there are other benefits: “We use all hot-runner molds,” Watson notes. “Too long a mold-open time leads to nozzle drool. If we lower the nozzle temperature to prevent drool, we get other problems, like nonfills or freeze-off.”

The new robot grabs the metal sharpener inserts magnetically, then deposits them in a docking station and then re-grabs them with more critical alignment.

The robot uses sensors to ensure that it has grabbed each insert, and only one insert at a time, rather than two that may have stuck together. The robot’s electric eye also checks for precise insert positioning in the mold and halts the machine if it detects an error. “We have a tolerance of only 0.0005 in. on a side for positioning the insert,” Parkhurst says. DMT’s molds have one, two, four, or eight cavities.

The robot places the finished parts on a conveyor or in totes. It keeps count of the number of parts per box. If desired, the robot can be switched to “QC mode,” whereby it places parts in a QC bin for checking.

Watson likes another aspect of the robot programming, using Wittmann’s R8.3 Teachbox: “We can block out certain areas—tiebars, mold, conveyors, guards—where the robot is not allowed to enter. In the past, if we made a mistake in programming a robot, we could get a crash, which was very unpleasant.”

Bettke says DMT is thinking about replacing its first injection machine, the 1985 Nissei, with a Wittmann Battenfeld vertical press, which will have its own Wittmann 4.0 integrated cell. According to Watson, the 4.0 system is “fairly intuitive” and easy to use, once you understand the basic principle.

Related Content

Smart Granulator Control Integrates Size-Reduction Systems, Enables Predictive and Knife Maintenance

NPE 2024: Conair’s New SG Control is available for its Viper Granulators

Read MoreWhat to Look for in High-Speed Automation for Pipette Production

Automation is a must-have for molders of pipettes. Make sure your supplier provides assurances of throughput and output, manpower utilization, floor space consumption and payback period.

Read MoreAutomation in Thermoforming on the Rise

Equipment suppliers’ latest innovations exemplify this trend driven by factors such as labor shortages, higher-speed thermoformers and tighter quality control.

Read MoreBeyond the Work Center: Using MES for Data-Driven Decisions Across Manufacturing Operations

Move past “is the job running” and “will it finish on time,” and apply MES to inform workflows ranging from accounting, inventory control, planning, material logistics, quality assurance, engineering and shipping.

Read MoreRead Next

Making the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More