Is Your Extrusion Line Due for a Controls Upgrade?

Most processors understand the warning signs that indicate when it’s time to replace items subject to mechanical wear. But they don’t have the same instincts regarding machine control. Here’s some guidance.

Line 4 is making good product, although it has been down lately for unscheduled maintenance. At this time, operations personnel may wonder if it’s a good time for a controls upgrade. Unscheduled maintenance on any line indicates there is a problem, but the severity of the problem cannot be fully understood until one understands the root cause. In doing so, you will learn not only the severity of the problem but also the risk of reoccurrence.

A good preventive maintenance program can result in the mechanical life of machinery lasting as long as 40 to 50 years. Almost all extrusion processors understand the warning signs that indicate when it’s time to replace items subject to mechanical wear: barrels, screws, bearings and more. Unfortunately, evaluation of machine control is not always as straightforward as you might assume, and simple repairs frequently box manufacturers into a corner.

An easy way to determine whether a control upgrade should be considered would be to ask yourself this question: “Is eBay one of my suppliers?” When controls experts ask this question of extrusion personnel, many look at each other, smile and chuckle, then say, “You bet they are!” What they are really saying is the control products in their electrical panel are no longer available from the manufacturer, forcing them to find products that are left over from someone else’s upgrade to keep their line running.

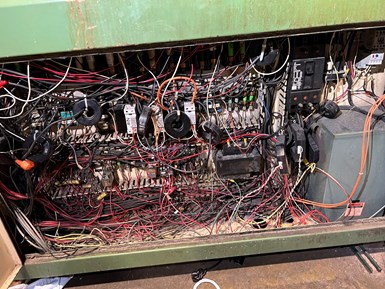

When you open your control panel, is this what you see? Controls experts call it a rat’s nest and it’s a pretty clear indicator your extrusion line is due for an upgrade. Photo Credits: Integrated Controls Technology

What is interesting is that most processors don’t act on the issue but accept it as solving the problem because they do not understand the root cause. If the management responsible for production truly understood that this approach to obsolescence will eventually lead to long-term downtime, they would be up all night worrying about losing customers in the future and the assumed liability associated with faulty equipment in regard to worker safety.

Evaluation of machine control is not always as straightforward as you might assume, and simple repairs frequently box manufacturers into a corner.

Another type of high-risk obsolescence involves the use of a proprietary communication network in machine control. This outdated topology is typical in control systems that are more than 20 years old. These designs include the Allen-Bradley Data Highway and Remote I/O or “Blue Hose” and the Parker SSD “Link” system. Proprietary communication networks are usually connected to obsolete and unsupported products that cannot be upgraded without upgrading the entire control system. This limits the options when a failure does happen and is a recipe for extended downtime.

No Band-Aid Solutions

Some maintenance staffs have attempted to remove the risks by installing single-loop temperature and discrete controls, virtually going backward in technology to keep the line running, as opposed to improving the line. Although, this approach may get the line running, it is not an engineered solution designed around UL or safety standards which are commonly used in more recent control designs and is simply “kicking the can down the road.”

Aside from control component failure, it is also possible that a mechanical failure can be an indication you are in need of an upgrade. For instance, a broken or locked screw may be the result of an operator starting an extruder with a cold heater zone. This can happen with an inexperienced operator who is not fully aware of the consequence, even though it may have been explained to them during training. It is better to prevent such an occurrence with a newer control system than training them on what “not” to do.

A nonoperator-related mechanical failure that can result in machine damage is a runaway heat condition. This is a common problem with older control systems and some newer simplistic systems using individual temperature controllers. This problem is not easily spotted by an operator until something bad happens or significant scrap occurs. Newer systems, designed by specialists in the field of extrusion, alert the operator and have a safe system shutdown prior to any damage occurring.

Operating an extrusion line with outdated or jerry-rigged controls can impact both safety and profitability.

The need to upgrade may not be based upon failure-related downtime alone; there are other factors that can be indicators that you need an upgrade. It is no surprise that it is getting more difficult to find skilled workers to operate machinery. Dr. Kirk Cantor of Pennsylvania College of Technology recently stated “20% of scrap is due to how well people do their jobs.” As unskilled workers continue to enter and exit the workforce, the more likely this is to occur on older equipment.

Time to Adapt Machine to Worker

The issue is related to the changing workforce and the retirement of the Baby Boomers. For years, we have adapted the worker to the machine. While this has been a successful method in the past, we must now start adapting the machine to the worker to reduce the possibility of scrap due to operator error. For this reason, the operator interface needs to be easy-to-use and understand in order to reduce scrap from errors and shorten the time required to train new operators.

Most maintenance personnel agree that the majority of time spent in unscheduled maintenance is in the determination of what went wrong. Much of it is attributed to a lack of documentation and machine diagnostic capabilities. It is easy to spot machines that are the primary culprits of such problems just by looking inside the enclosure. If the wires are out of the wireways and are a tangled mess that resembles a “rat’s nest,” it is because the maintenance technician needed to trace wires by hand to help determine the source of the problem.

“Some 20% of scrap is due to how well people do their jobs.”

Once the problem is identified and corrected, the next task is at-hand, and the work left behind in disarray results in a longer downtime for the next failure. On some occasions, I have even observed components not securely attached to the panel or disconnects that are not attached to the mechanism on the enclosure, creating safety hazards that could lead to injury and liability. Again, all solid evidence an upgrade is needed.

Finally, although not fully comprehensive, there is the reason for embracing the technological advancement known as Industry 4.0. Systems of yesterday told you when it was too late, because something has already gone wrong or the system has already failed. The future is “predictive maintenance” or notification prior to a catastrophic event. Systems using “guidance” can help you predict potential failure or scrap by identifying the pending concern before it becomes an issue.

This guidance assists the maintenance team in supporting the equipment and maximizing machine uptime, driving higher efficiency and throughput over time. While this may seem a small advantage, consider the dependency many drivers now rely on with the development of blind spot notification, guidance on the backup camera with proximity sensors or even self-parking and driving capabilities. Do you really want to drive your older car now?

ABOUT THE AUTHOR: Scott Barlow is the CEO of Integrated Control Technologies, which specializes in aftermarket drive and control upgrades for extruders. He has written a white paper that was published by the Society of Plastic Engineers on The Energy Differences of DC and AC Drives and Motors on Extruders.” Barlow has spoken at many technical conferences and has performed over 500 energy studies on extruders. Contact: 972-906-7445; sbarlow@integratedcontroltech.com; integratedcontroltech.com

Related Content

Single vs. Twin-Screw Extruders: Why Mixing is Different

There have been many attempts to provide twin-screw-like mixing in singles, but except at very limited outputs none have been adequate. The odds of future success are long due to the inherent differences in the equipment types.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read MoreWhat to Know About Your Materials When Choosing a Feeder

Feeder performance is crucial to operating extrusion and compounding lines. And consistent, reliable feeding depends in large part on selecting a feeder compatible with the materials and additives you intend to process. Follow these tips to analyze your feeder requirements.

Read MoreThe Importance of Barrel Heat and Melt Temperature

Barrel temperature may impact melting in the case of very small extruders running very slowly. Otherwise, melting is mainly the result of shear heating of the polymer.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read More