Time, distance and life experience often conspire to alter perceptions once thought immutable. When he left Erie, Pa., in 1995 after graduating high school and headed to Chicago and Northwestern University, Philip Katen believed his exit from his home ciy was final, leaving behind the lake and his father’s moldmaking and injection molding business—save visits—for good.

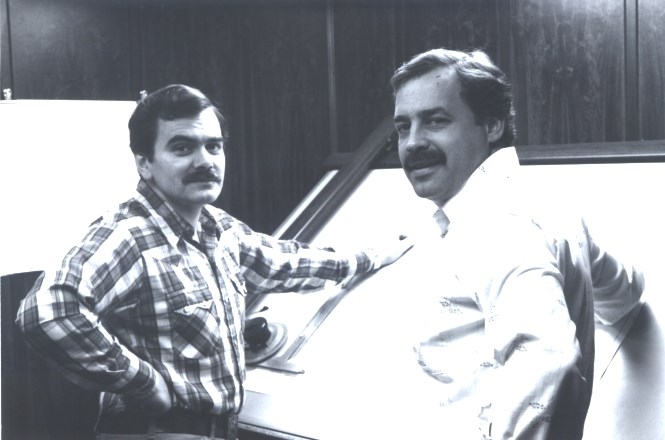

That same summer, Plastikos, the injection molding operation cofounded in 1989 by his father, Timothy Katen, along with Gary McConnell, Bill Fogleboch and David Mead, moved into a brand-new facility sized to accommodate up to eight machines. That company began life in a rented business incubator in Erie with just a single injection machine. Plastikos was Katen and Mead’s second collaboration. Their first launched in November 1978 with the founding of moldmaker Micro Mold in a rented garage before they built their own facility in 1984.

“What a unique and extremely rare opportunity it is for anybody to be able to work for your family company—to play a direct, impactful role.”

While Philip Katen earned a double major in industrial engineering and economics from Northwestern over the next four years, Plastikos continued to grow, more than doubling its space to accommodate 16 machines. In August 1999, Katen took a consultant job with Deloitte upon graduating from Northwestern, working within its Strategy and Operations practice. In 2003, as part of the firm’s Scholars program, Katen enrolled in Duke University’s Fuqua School of Business, where he set about earning his MBA.

Micro Mold started life in 1978 in a rented garage in Erie, Pa.

That’s when Katen’s coursework and consulting job led him to see Micro Mold and Plastikos in a new light. Not as the shops where he and his brother had swept floors, cleaned machines, inspected and packed parts, and cut the grass in high school or on breaks from college, but as the kind of dynamic and exciting business opportunity that he helped clients build at Deloitte.

“Business school, more than anything, brought out a bit of that entrepreneurial spirit in me,” Katen says, “and I saw the opportunity that the companies had, and what a unique and extremely rare opportunity it is for anybody to be able to work for your family company—to play a direct, impactful role.” Katen and his father began to lay out a path for him to come back to Erie and Plastikos. Throughout that time, the company continued to expand, adding space for a third time and growing to 27 injection molding machines.

Long before business school had opened his eyes to the career opportunity he had at home, Katen says his father defined a route Philip and his brother Ryan could take if they ever wanted to join the family business, including education at a college or trade school coupled with relevant job experience.

“After school, my dad made it clear to my brother and me that you had to work somewhere else for at least a couple of years in order to gain the experience of working for another company, other managers and bosses,” Katen says, “and also in a field that would yield valuable experiences and insights that would be applicable back at the company.” After completing his MBA and commitment to Deloitte, Katen moved back to Erie in January 2007, starting full-time work at Plastikos on Feb. 1, 2007.

Katen’s brother Ryan took a very similar path. Four years younger than Philip, Ryan attended Purdue University in West Lafayette, Ind., earning an undergraduate and then a masters degree in industrial engineering. Upon graduation, Ryan immediately went to work for medical-device manufacturer Boston Scientific in upstate New York. After a few years of hands-on manufacturing experience there, he also came back home to rejoin the family companies in late 2006, just before Philip returned to Erie.

At this time the company began its shift into more medical molding, starting with non-cleanroom and whiteroom work of Class I and Class II medical-device components, while building towards cleanroom operations, including the addition of a small 300-ft2 certified ISO-7 cleanroom on the main molding floor in 2009-2010. Thats same year, Tim Katen and David Mead retired, more than three decades after starting Micro Mold in that rented garage in 1978. The elder Katen remains involved to this day, sitting on the company’s board and consulting with his sons on a regular basis.

Cleanroom Commitment

The push to increase medical business came to a head in 2014, when Plastikos initiated a major 17,000-ft2 expansion, that included a 10,000-ft2 ISO-7 cleanroom with 10 injection machines, as well as a dedicated quality lab, toolroom, mold storage, office and meeting space spread across two floors. At that time, Plastikos’ molding machine fleet grew to 37 total presses—27 whiteroom machines plus the 10 in the cleanroom.

Plastikos has 27 whiteroom and 10 cleanroom molding machines, while Plastikos Medical has another 10 cleanroom molding machines.

Seeking even more medical customers, the company launched Plastikos Medical, designing and building a new, standalone 25,000-ft2 facility and business with a 12,000-ft2 ISO-7 cleanroom molding floor that could accommodate up to 10 machines. This business officially began production right after Labor Day 2019 under Ryan’s leadership, with five cleanroom molding machines. Five additional machines were added from late 2019 through November 2020, with the ninth and 10th presses—all Arburg’s—scheduled to start up in mid-December. Rob Cooney, manufacturing manager at Plastikos, who joined the company in 2002 after graduating from Penn State’s Plastics Engineering program, is the third partner in that business along with the Katen brothers. All three went to the same high school in Erie, with Cooney between Philip in Ryan in age.

In business just a little over one year, Plastikos Medical is already finalizing a Phase II expansion plan, with architectural and engineering design on a 24,000-ft2 addition slated to be completed last month. The new space will accommodate up to an additional 15 ISO-7 cleanroom molding machines that will be added over the next three to five years. Groundbreaking is anticipated for the spring of 2021, and completion a year later.

Staying a Step Ahead

While its customers only require ISO-8-certified cleanrooms, all of Plastikos’ cleanrooms are certified to the higher ISO-7 level, and Philip Katen says they’re often operating closer to an ISO-6 level. “The benefit there is you’ve got a much cleaner environment, much more pristine air, with significantly less particulate, and thus a dramatically lower risk of contamination to the molded components and the finished end device—which our customers in the medical device space love, because that’s just a lower component of risk in their overall risk analysis and supply chain.”

Plastikos Medical’s cleanroom molding floor operates in a lights-out fashion for two of its three shifts.

In addition to regular standard ISO-13485 medical-device certification, Plastikos Medical is also certified for two biocontamination-related sub-standards with independent lab verification. It’s another step that goes beyond what customers require but also tries to anticipate future needs. The same philosophy informs Plastikos’ expansions.

“The strategic plan is to always stay at least one or one-and-a-half steps ahead of our customers, their growth and their demands, so that we’re supporting them every step along the way and never leave them high and dry or in a pinch,” Katen says. “So keeping that production capacity ahead of where they need to be today and then continuing to grow into that reserve capacity is in direct support of our customers’ growth.”

Lights-Out Operation

While Plastikos Medical plays an outsized role in the group of companies’ growth, it has an undersized impact on its payroll. Micro Mold and Plastikos have 23 and 155 full-time employees, respectively, while the newest unit has just seven full-time workers, with some support from the main molding site as needed. A largely lights-out operation, Plastikos Medical has staff on hand for only one of three shifts, so no one is there for 14 hr or more per day, with weekend operations completely unmanned.

“If nobody is there for hours on end, the risk of any kind of contamination within the cleanroom during those ‘lights-out’ production hours is effectively zero.”

To achieve this, Katen says the company takes automation “to another level.” In addition to all the machines featuring Arburg’s integrated three-axis multi-lift robots with custom end-of-arm-tools, Plastikos Medical also deploys RJG’s cavity-pressure sensors and eDart quality-monitoring systems, plus integrated process-monitoring software, custom automated boxing/packaging systems, and automated material-handling systems that the firm developed over the years, among other Industry 4.0 technologies.

In 2019, Plastikos expanded with the addition of Plastikos Medical; that unit will break ground on another expansion in the Spring of 2021.

At the end of the day, the lack of people also means a lack of dirt and dust. “Lights-out increases quality assurance, including dramatically reducing the risk of contamination by not having people there, since people are your number one vector for particulate contamination,” Katen says. ‘’If nobody is there for hours on end, the risk of any kind of contamination within the cleanroom during those lights-out production hours is effectively zero.”

Finished Basement

People and contaminants aren’t the only thing that’s scarce on the production floor. Something you’ll never see in Plastikos and Plastikos Medical’s molding rooms is auxiliary equipment. From the beginning, both facilities were designed to keep utilities, material handling and resin drying off the main floor, residing instead below the presses in a basement area. At Plastikos, utilities are all located in a tunnel running directly below the machines, with ceilings high enough to stand comfortably.

In the 2014 expansion that included the larger ISO-7 cleanroom, the company took the concept further, upgrading from a utility tunnel to a full basement underneath the new molding floor, featuring 8- to 9-ft ceilings. At the brand-new medical facility, the basement has been made even larger, extending its height to 10 ft from floor to roof deck, with even more material lines, colorant lines, regrind feeds, equipment and utilities.

“That strategy enables us to add more press capacity to the same building footprint, which benefits our customers first and foremost,” Katen says. “Taking the equipment off the molding floor and putting it in the basement also yields a much cleaner—and, you could argue, safer—work environment on the molding floor. You don’t have those additional components or additional pieces of equipment that could potentially contaminate the cleanroom space.”

Picky Partners

Plastikos’ rise over the years, like any business, is fueled by winning new business, but the manner in which the company takes on new customers is as strategic as anything it does. Before Plastikos agrees to work with a new customer, it first considers its existing ones.

“We’re very selective, arguably as selective as our customers are,” Katen says. “So even at dinners with new prospective customers, I’ll share with them that we’re also strategically evaluating you, analyzing to make sure the prospective business opportunity is a good fit, as much as we know that you’re evaluating and critiquing us.”

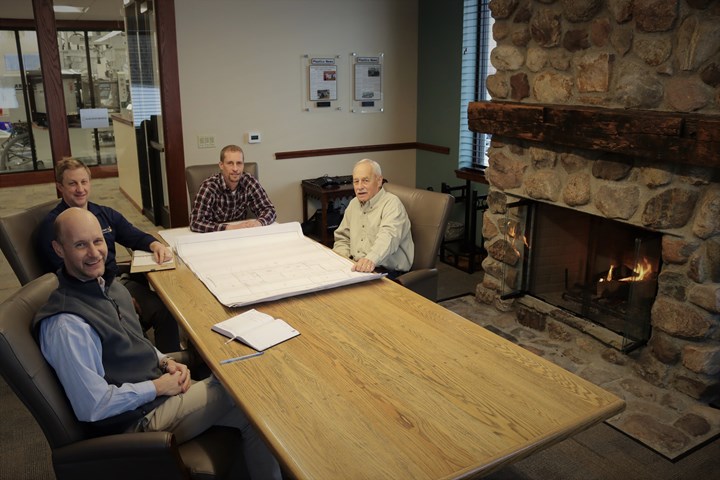

Left to right: Philip Katen, Rob Cooney, Ryan Katen and Tim Katen in the company’s conference room with the cleanroom visible in the background.

That level of scrutiny is seen as a responsibility that Plastikos has to its existing customers, particularly long-term ones, according to Katen. If an ill-fitting project added in haste goes sideways, everyone feels the impact. “We know that it takes a lot of work, a lot of talent, a lot of know-how and expertise to serve our existing customers,” Katen says, “and if we were to bring in the ‘wrong’ new customer—one that for whatever reason didn’t ‘fit’ well—then very quickly that can take away key limited resources—precious resources—and consume a disproportionate amount of that engineering talent, technical talent, tooling talent that’s in short supply and key to our collective success with our customers.”

That exacting evaluation extends to the parts Plastikos is asked to mold. “We’re very selective in terms of what the parts look like, what kind of devices do they go into: Is it a good fit in size, geometry, and material? Does it complement our expertise, know-how and experience, or not? And in some cases, if it’s something new, but not way out in left field, then definitely we’re quite interested to learn more and evaluate internally if we think it’s a viable project that may expand our knowledge and capabilities.”

A Second Chance

Entering its fourth decade with a second generation at the helm, Plastikos exists today despite a brush with extinction during the painful recession of the early 1980s, when Katen’s father told him “a stiff breeze” could have wiped out the fledgling company. “He’s relayed the story that the bank really should have foreclosed on Micro Mold in those early years, but gave them one more chance and believed in them,” Katen says. “Ultimately, their accountant, their banker and insurance agent went to bat for Tim and Dave, and they were given that extra chance and just enough time. They were able to find a way against the odds to pull it out and turn it around.” More than 40 years later, as the company grows and enriches Erie, the optimism of those early allies seems prescient.

Micro Mold’s founders, Dave Mead (left) and Tim Katen in 1978.

Related Content

Custom Molder Pivots When States Squelch Thriving Single-Use Bottle Business

Currier Plastics had a major stake in small hotel amenity bottles until state legislators banned them. Here’s how Currier adapted to that challenge.

Read MorePlastic Compounding Market to Outpace Metal & Alloy Market Growth

Study shows the plastic compounding process is being used to boost electrical properties and UV resistance while custom compounding is increasingly being used to achieve high-performance in plastic-based goods.

Read MoreUse Cavity Pressure Measurement to Simplify GMP-Compliant Medical Molding

Cavity-pressure monitoring describes precisely what’s taking place inside the mold, providing a transparent view of the conditions under which a part is created and ensuring conformance with GMP and ISO 13485 in medical injection molding.

Read MoreCompact Solution for Two-Component Molding

Zahoransky’s new internal mold handling technology foregoes the time, space and money required for core-back, rotary table or index plate technologies for 2K molding.

Read MoreRead Next

Training Pays Off in Productivity

A skilled and efficient workforce provides a decisive edge against competition and improves the bottom line.

Read MoreMMT Recognizes Moldmaking Innovators at Amerimold

Honored mold manufacturers demonstrate excellence in overall innovation, efficiency, quality and commitment.

Read MoreDigital Manufacturing: Two Medical Molders Embrace Industry 4.0

‘Digitalization’ and ‘connectivity’ are loaded terms—shorthand for a whole new way of doing business. It can’t be accomplished in one go. But two Midwest molders in the sensitive medical field are already feeling the benefits of their initial steps in that direction.

Read More