‘Light’ Grooves Offer Big Boosts in Film Processing

Close Up: Extrusion

Blown film is main target for technology billed as an option to smooth bore feedthroats in extrusion.

A new type of grooved-feed section has shown promise in solving a wide range of film extrusion problems while at the same time adding stability to the overall process and making more judicious use of energy.

Called Light Groove Feed (LGF) technology and developed by Gloucester Engineering Corp., Gloucester, Mass., it is promoted as an option to smooth-bore extruders. Gloucester has roughly 100 of them in the field, mostly at blown film processors. The technology has been applied to cast film and foam extrusion lines as well. LGF has been retrofitted to existing extruders in sizes from 30 to 150 mm. It requires no change to screw design or drive size. The technology is not intended to replace the intensively grooved feed sections common for processing HMW-HDPE film.

“Smooth-bore extruders have always been viewed as versatile, cost-effective machines requiring little maintenance,” notes Bill Hellmuth, Gloucester’s product group director for blown film. “They generate a moderate amount of torque and pressure, and as a result generate less wear than intensively grooved-feed machines. But all extruders rely on differential friction between the screw and barrel to provide forward conveyance. With today’s machining techniques, the surface finish inside a feed throat may be the same as on the surface of the screw. Consequently the differential friction may be completely reliant on a properly set temperature profile. Even with a dedicated temperature-control unit, this is not reliable and can result in poor throughput stability.”

LGF technology features a series of shallow axial grooves that provide a light rotational resistance, thereby increasing the mechanical friction between the screw and barrel compared with smooth-bore machines, explains Dr. Mike Andrews, Gloucester’s director of process technology.

The groove depths are proprietary. They are designed only to promote forward conveyance of the pellets as the screw rotates, Andrews explains. This reportedly reduces the screw “bridging” problem that is fairly typical with high-slip resins and additives. The technology also reportedly creates a more consistent feed rate with varying pellet sizes. This is important with extruders of 50-mm or smaller diam., Andrews states.

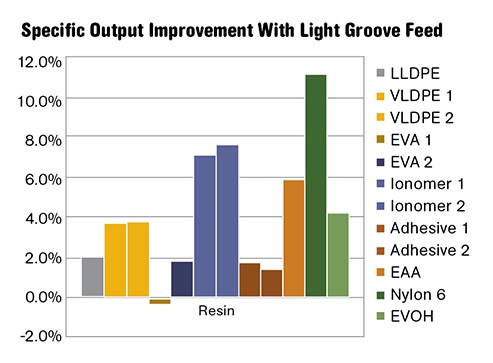

This design adds less than 10-12% to torque requirements and needs no special cooling and no changes to a standard smooth-bore screw design. Tests reportedly have shown that equipping an extruder with LGF instead of a smooth-bore feed section can increase specific rate by 2% to 11% across a wide range of resins, can improve specific energy 6% to 10%, and reduces rate/pressure fluctuations by 30% to 50%.

“Without a consistent frictional difference between the barrel and screw, a processor can experience variable extruder feed rate or even total loss of forward conveyance,” Andrews notes. “Blown film extrusion problems such as changing frost-line height and layflat width can lead to web wrinkling. In extreme cases, portions of an entire film layer can be missing. Feed rate can be limited in the feed throat by the effects of pellet geometry, hardness, or coefficient of friction, as well as presence of reclaimed pellets or trim, liquid tackifier, or additive levels.”

LAB TRIALS SHOW BENEFITS

At the request of a blown film processor that was considering an LGF retrofit, Gloucester recently tested the device side by side with a smooth-bore machine of the same size. (50 mm, 30:1 with identical barrier mixing screws). A wide range of materials was tested.

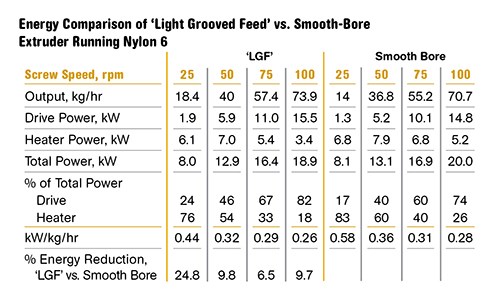

Each extruder was equipped with five heat/cool zones and one water-cooled feed-throat zone. All tests were run with feed zones at 100 F, and with a ramped barrel-temperature profile (i.e., lowest temperature at feed zone, highest at discharge end). All comparisons were conducted at 25, 50, 75, and 100 rpm, and the conditions were stabilized for a minimum of 20 min at each rpm.

The results showed that nylon 6, ionomers, and EAA had the biggest improvement in specific rate (see chart right) and torque; EVA, nylon 6, adhesive, and LLDPE saw the most reduction in rate variation; and VLDPE, EVA, and LLDPE saw the greatest reduction in pressure variation.

During testing of nylon 6, specific energy was compared between LGF and smooth-bore technology. The results (see table p. 14) show a reduction in kWhr/kg of 6.5% to 9.8% in the normal rpm range. Also compared were the drive power and heater power proportions of total power used. Although the LGF extruder uses less overall energy per kilogram of resin processed, its proportion of drive power is higher than the smooth-bore, indicating better conveying efficiency.

COMMERCIAL SUCCESSES

In the field, Gloucester installed LGF on a three-layer blown film line with two 75-mm and 90-mm, 30:1 extruders, both with smooth-bore feed sections. The line was designed to run various packaging films based on HDPE, LLDPE, ionomer, and recycled material.

During commissioning of the line there were issues related to bubble stability, including the occasional complete loss of extruder output, particularly when running MMW-HDPE. After the initial startup, the instability got worse over time. The type of resin, grade of resin, addition of color, and feed-throat temperature all contributed to the overall instability.

Here, LGF demonstrated an improvement in output stability leading to overall better bubble stability, reduced width variation, reduced gauge variation, and fewer film wrinkles. It also provided a much larger processing window, increased specific output, and improved energy efficiency.

The second field trial involved a five-layer blown agricultural stretch-film line with one 130-mm, two 90-mm, and two 75-mm smooth-bore extruders, all with 30:1 L/D. This processor was encountering a problem in running 18% EVA copolymer with UV-stabilizer masterbatch. Injection of liquid PIB was limited to 3.1% by weight, though at least 5% PIB was required, due to poor mixing of the EVA with PIB.

There were also excessive variations in layflat, and output fluctuation of ±1.4%. These problems occurred also when the line ran LLDPE. After the LGF retrofit, this line experienced a wider processing window for the blend of 18% VA, PIB, and UV stabilizer. The feed rate was much more consistent.

“Our tests in the lab and experience with retrofits show that LGF improves output stability—leading to better bubble stability—reduces variations in width and gauge, and cuts down on film wrinkles,” Andrews states. “The technology has also been proven to widen the processing window, increase specific output, and improve energy efficiency.”

Andrews also sees possible fits for the technology in tubing and profiles because those processes typically require tight tolerances.

Related Content

What to Know About Your Materials When Choosing a Feeder

Feeder performance is crucial to operating extrusion and compounding lines. And consistent, reliable feeding depends in large part on selecting a feeder compatible with the materials and additives you intend to process. Follow these tips to analyze your feeder requirements.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read MoreHow to Select the Right Cooling Stack for Sheet

First, remember there is no universal cooling-roll stack. And be sure to take into account the specific heat of the polymer you are processing.

Read MoreMedical Tubing: Use Simulation to Troubleshoot, Optimize Processing & Dies

Extrusion simulations can be useful in anticipating issues and running “what-if” scenarios to size extruders and design dies for extrusion projects. It should be used at early stages of any project to avoid trial and error and remaking tooling.

Read MoreRead Next

Making the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More