Metallocene VLDPE Is a Tough New Contender for Flexible Packaging

A new metallocene catalyzed, very-low-density polyethlyene (mVLDPE) from ExxonMobil Chemical Co., Houston, reportedly offers the excellent toughness associated with mLLDPE plus lower heat-seal temperatures and other advantages over conventional Ziegler-Natta VLDPEs or ULDPEs for flexible packaging.

Produced with Exxpol catalyst technology in a gas-phase process plant at Mont Belvieu, Texas, new Exceed 1012CA has a density of 0.912 g/cc and MI of 1.0. It is aimed at monolayer and multi-layer flexible packaging for meat and dairy products, snacks, prepared convenience foods, and frozen foods. Other potential uses include industrial packaging such as heavy-duty sacks and impact modification of other resins.

Sealing, impact, opticals

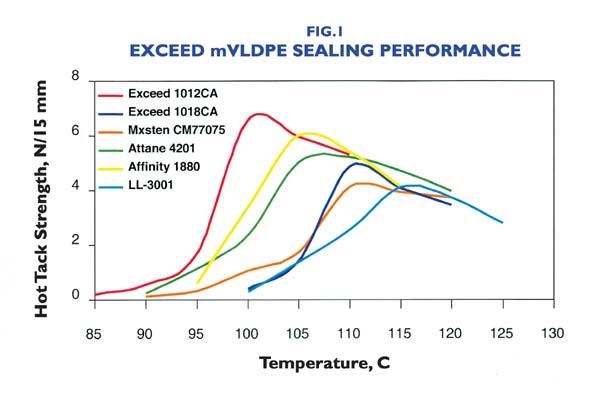

In monolayer blown films, Exceed 1012CA mVLDPE has been shown to outshine monolayer conventional LLDPE and ULDPE, as well as mLLDPE and plastomers in sealing performance (see graph on next page). The comparison includes LL3001, a 1-MI, 0.918-g/cc hexene LLDPE from ExxonMobil; Exceed 1018C, a 1-MI, 0.918-g/cc mLLDPE from ExxonMobil; Mxsten CM77075, a 0.5 MI, 0.9065-g/cc enhanced hexene LLDPE from Eastman; Attane 4201, a 1-MI, 0.912-g/cc ULDPE from Dow Plastics; and Affinity 1880, a 1-MI, 0.910-g/cc metallocene plastomer from Dow.

Tests show that Exceed 1012CA mVLDPE has both the lowest seal-initiation temperature and the broadest hot-tack window, along with excellent hot-tack strength. With mVLDPE, fabricators/converters can use substantially lower film sealing temperatures (down to 185 F), which results in faster sealing line speeds.

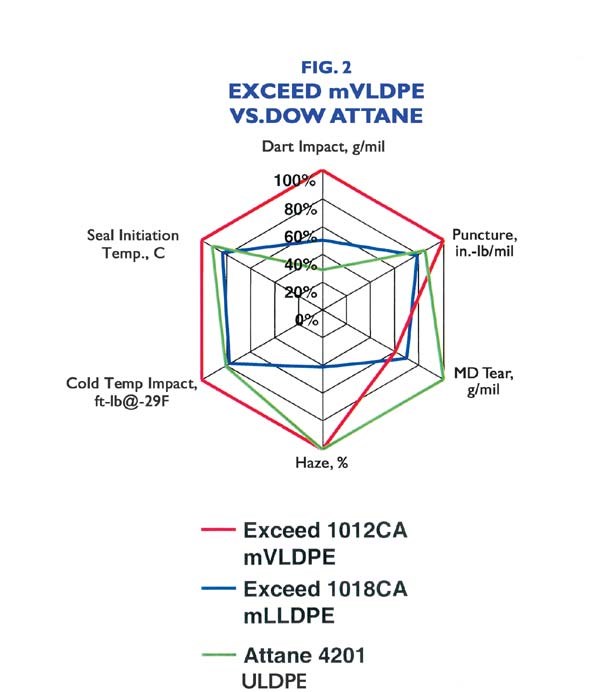

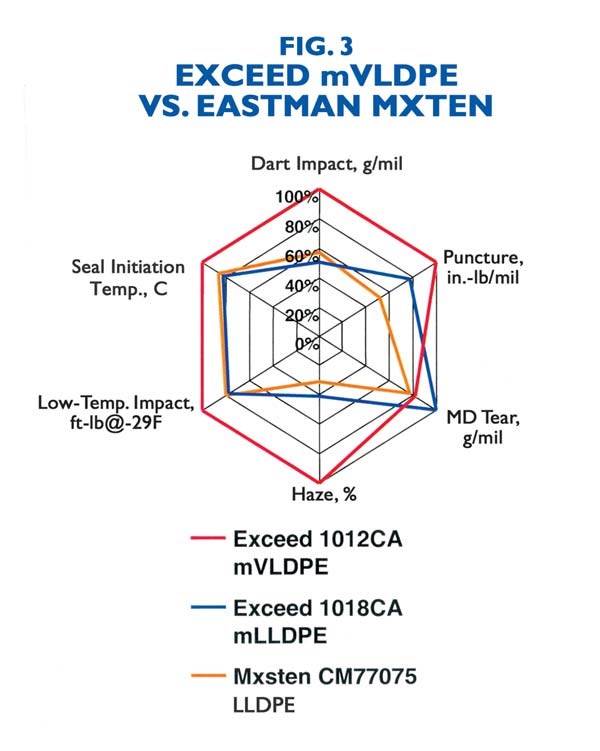

The new grade also boasts dart impact three times that of conventional VLDPE, along with exceptional puncture resistance (see graphs below). As a result, film produced with it can be significantly downgauged, providing an economical alternative for poultry and meat packaging applications, according to ExxonMobil. Exceed 1012CA also boasts better low-temperature impact performance for frozen-food packaging.

In addition, the excellent haze and gloss properties of Exceed 1012CA are advantages for retail displays and barcode scanning of packages. These properties can be improved substantially with the addition of only 5% to 10% LDPE. A comparison of Exceed 1012CA and Attane 4201 showed that though the ULDPE by itself has lower haze and higher gloss, adding 10% of either of two ExxonMobil LDPEs (7.5 and 0.75 MI) produced higher clarity and gloss with Exceed 1012CA than with Attane 4201.

The two "spider" graphs on the previous page compare Exceed 1012CA with Attane 4201 and Mxsten CM77075. The mVLDPE is shown to surpass the Attane grade in dart impact, puncture resistance, low-temperature toughness, and seal-initiation temperature. It also outperforms the Mxsten grade in all of those same properties, as well as haze value.

Related Content

-

Prices for PE, PS, PVC, PET Trending Flat; PP to Drop

Despite price increase nominations going into second quarter, it appeared there was potential for generally flat pricing with the exception of a major downward correction for PP.

-

Prices of All Five Commodity Plastics On the Way Up

Despite earlier anticipated rollover in prices for most of the volume commodity resins, prices were generally on the way up for all going into the third month of first quarter.

-

First Quarter Looks Mostly Flat for Resin Prices

Temporary upward blips don't indicate any sustained movement in the near term.