Molder Expands Plant, But That’s Just the Beginning

Wescon cuts ribbon on a new addition and adds presses as part of a strategic plan to double its business.

In today’s ultra-competitive environment, processors that aren’t moving forward run the risk of being left behind. Just ask Wescon Plastics, Wichita, Kan. The 43-year-old custom injection molder recently completed a $3.5-million plant expansion that not only upgraded the plant infrastructure, but also expanded the facility to enable further growth. An additional $2 million was invested in new molding machines, automation, and ERP. In late October, the expansion was formalized with an open house and ribbon-cutting ceremony that was attended by key customers, suppliers, and local government officials.

Wescon specializes in molding a wide range of materials, from HDPE and PP to engineering resins such as nylon and PEEK. Privately held by Nova Capital Management, Wescon molds tight-tolerance parts for industries such as oil and gas, transportation, electrical, batteries, lawn equipment, and HVAC. It runs 33 machines ranging from 30 to 610 tons and employs 130. Wescon runs three shifts 24:5 in its 90,000+ ft² plant, which was expanded by about 8500 ft². Its newly purchased injection machines include a 30- and 500-ton press from Engel, and a 250- and two 500-ton machines from Toyo (represented by Maruka USA).

Wescon’s molding activities are supported by a range of secondary operations such as hot stamping, pad printing, assembly, and both ultrasonic and hot-plate welding. It is also a user of Autodesk Moldflow analysis software for tool and process/part design. Wescon also has a tooling facility in-house with full design and prototype capabilities. Primarily, it builds and manages tooling projects for production. The firm also boasts long-term relationships with domestic and overseas moldmakers that are utilized depending on customer requirements.

“The equipment, facilities, and utilities expansions and enhancements will provide Wescon Plastics with the means to double our business,” states Jan Acker, who became Wescon’s CEO in September. Acker adds that the firm has a strategic plan to accomplish this objective. “As we move forward in our implementation of this plan over the next several years, we will be adding jobs in manufacturing, engineering, and management.”

Added Mat Mount, the molder’s CFO, “Our investment in the most advanced technology today is a commitment to our customers and the industry as a whole.”

According to Acker, the plant expansion will allow Wescon to better serve existing customers as well as to grow and enhance its capabilities. Up to 15 to 20 new machines can be integrated as growth dictates, and the power and water infrastructure was substantially upgraded.

Ernie Gerlach, who has worked in sales at Wescon for 22 years, puts it this way: “The $5 million investment allows us to compete with other top-of-the-line molders in a significantly improved facility with updated equipment.”

Officials from Enersys, Johnson Controls, and Wescon Controls were among the customers attending the open house. Noted Dan Bohn, Enersys sr. procurement manager, plastics, “It is a special privilege to be part of the open-house events and to see the results of 18 months of hard work, sweat equity, and dedication as you kept production running ‘business as usual’ even through all of the renovations, improvements, new presses, etc.”

In addition to 22-year veteran Gerlach, at the open house Wescon also recognized Eva Harrison, a machine attendant who has worked for the company for 36 years; and Shirley Garcia, who has worked in shipping for 38 years.

Related Content

Plasmatreat's Technology is Transforming Manufacturing with Innovation and Sustainability

NPE2024: Advancements and forward-thinking initiatives in plastics manufacturing will be highlighted.

Read MoreLow-Smoke, Non-Halogen Polyolefinic Compound for Armored Cables

Avient’s latest addition to its ECCOH portfolio is designed to prevent environmental stress cracking in low- and medium-voltage cable sheathing.

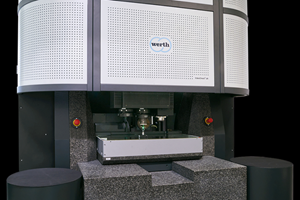

Read MoreUpgraded CT Scanning and Multi-Sensor Coordinate Measuring Machines

Werth’s TomoScope S Plus 240 systems boast more than double the measuring volume as their predecessor with almost the same size.

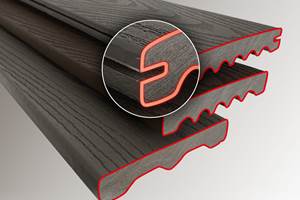

Read MoreInline Inspection System for Wood Plastic Composites

Pixargus’ ProfilControl 7 DX WoodPlasticComposites measure all dimensions and geometrics, including deep grooves.

Read MoreRead Next

Beyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More