More Choices for Grinding, Shredding

Many granulators on display at the K 2007 show in Dusseldorf last October were big models—150 to 200 hp—to enable higher throughputs or reclaiming larger parts and chunks. For example, Rapid Granulator from Sweden brought out the 600 model, the largest in its “open-hearted” series, which allow fast access to all internal components. It has a 600-mm-diam. rotor, 100 mm more than the next largest size.

The modular design of this series allows optional configuration for injection molding, extrusion, blow molding, or recycling. A new option is different configurations at the rear of the cutter housing to provide a narrow space for grinding thick, rigid scrap or a wide space to grab and ingest bulky materials. Removable hardened side plates correspond to the two shapes. The 600 Series can be 900, 1200, or 1500 mm wide and comes with a choice of five rotors (vs. two before) with three, five, or seven blades. Another brand-new feature is the mineral-composite base that’s said to reduce noise and vibration. Rapid has two prototypes operating in Sweden, one grinding heavy sheet scrap, the other industrial reclaim.

Rapid also added to the “open-hearted” series the 400-60 HD (Heavy Duty) model and the 400-120, the widest model in this series, designed for extra-wide molded and thermoformed parts.

Wittmann GmbH in Austria recently built a specially reinforced version of its MCP 100 large central granulator for a French automotive molder. It grinds massive purgings weighing over 60 lb—even handling glass-filled materials—at 3000 lb/hr in round-the-clock operation. It has reinforced walls and enlarged bearings.

Wittmann also introduced the MAS series of beside-the-press grinders with four-sided stationary knives that don’t need replacing.

PET BOTTLE GRINDERS

Three new granulators target post-consumer PET bottles. Probably the most unusual is the CentriCut single-shaft model from Nuga AG in Switzerland (represented here by Weima). The unit has a horizontal screw conveyor, which brings materials like bottles to the middle of the granulator and releases them directly onto the rotor. The feed rate is very even, and there’s no possibility of bottles bouncing out.

Herbold Meckesheim GmbH in Germany also incorporates force-feeding in a new large granulator for PET bottles. Model 80160 (800-mm-diam. rotor and 1600 mm wide) is for outputs up to 11,000 lb/hr, making it the largest force-fed granulator in the world, Herbold says. The company built the first one last year for a German recycler. Herbold’s U.S. office, formerly called Resource Recycling Systems, is now named Herbold Meckesheim USA.

Cumberland Engineering introduced a granulator with a new rotor design for post-consumer PET bottles that has replaceable seats for blades. The seats, or threads for the bolts holding the rotor knives, are believed to be the only ones on the market. They let recyclers change damaged threads off-line with less downtime and without using sub-standard thread-repair techniques.

Cumberland also introduced a sound-insulated edge-trim granulator that handles dual trims up to 2 mm thick at up to 550 lb/hr. Guide rolls are covered with elastomer to prevent breaking thin, brittle trim.

Hosokawa Polymer Systems built an unusually “quiet” granulator with new sound-abating features. A door on the feed chute closes automatically to reduce noise and fly-back. Blowers and ducts are also sound insulated.

SCREENLESS GRINDER NEWS

Moditec in France (recently acquired by Rapid), a specialist in screenless granulators with hook-type rotor teeth, showed a new integrated metal detector to prevent damage to the granulator from tramp metal. A low-voltage circuit includes the housing and rotor. If metal gets between the rotor and housing, it completes the circuit and shuts the machine down.

SHREDDERS, PULVERIZERS

UNTHA Shredding Technology in Austria, inventor of the four-shaft shredder, opened a U.S. office in Newburyport, Mass., late last year. It announced a new shaft-sealing method on its one-, two-, and four-shaft shredders, so that material doesn’t get into bearings and gears.

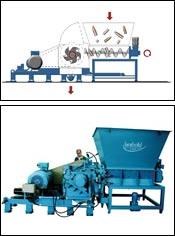

Weima Maschinenbau GmbH in Germany launched a high-torque, direct-drive system that uses four motors. This is believed to be the first use of this high-torque, four-motor direct drive on a single-shaft shredder. The Weima Direct Drive has been in operation for almost three years in Europe.

Also new from Weima is a protective rotor shell of a wear-resistant alloy. The replacable shell eliminates the need to replace the rotor in high-wear applications. Also new are rotor cutters with carbide inserts that last five times longer than D2 steel.

Pallmann Maschinenfabrik GmbH in Germany showed a new Eco Advanced version of its PKM pulverizers, available on all four models. The “ecological” version offers about 10% energy savings by using a slightly smaller motor for the same throughput.

Related Content

Scaling Up Sustainable Solutions for Fiber Reinforced Composite Materials

Oak Ridge National Laboratory's Sustainable Manufacturing Technologies Group helps industrial partners tackle the sustainability challenges presented by fiber-reinforced composite materials.

Read MoreInside the Florida Recycler Taking on NPE’s 100% Scrap Reuse Goal

Hundreds of tons of demonstration products will be created this week. Commercial Plastics Recycling is striving to recycle ALL of it.

Read MoreNew Facility Refreshes Post-Consumer PP by Washing Out Additives, Contaminants

PureCycle prepares to scale up its novel solvent recycling approach as new facility nears completion.

Read MorePurpose-Built System Enhances Capacity and Flexibility for Recycler

A Boston recycler invested in a turnkey shredding, granulation and elutriation system to expand its plastics reclaim business.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read More