Thermoformers running non-servo-eject trim presses will have access to a first-of-its kind automation solution thanks to new technology introduced recently by BMG. Its Mantis Robotic Trim Press Handler was developed by NAS Nalle Automation Systems, a BMG company, and is billed as the industry’s first robotic system that reliably handles the flow of parts ejected from any non-servo trim press, including those made by BMG competitors. The fully automated system reportedly can reduce labor requirements by up to 75%, and the modular robotic design allows for tool changeovers in under an hour. Mantis has been running since March at an undisclosed Midwest thermoformer on a line making PP lids.

Before this innovation, parts ejected from non-servo trim presses had to be manually separated and counted, a labor-intensive, error-prone and inconsistent process that limits the automation of downstream packaging functions. NAS solved this problem with its patent-pending Trim Press Receiver (TPR), which uses a unique separating mechanism to count and contain stacks of product, followed by a raking mechanism to take the product into the receiver for transfer by the robot.

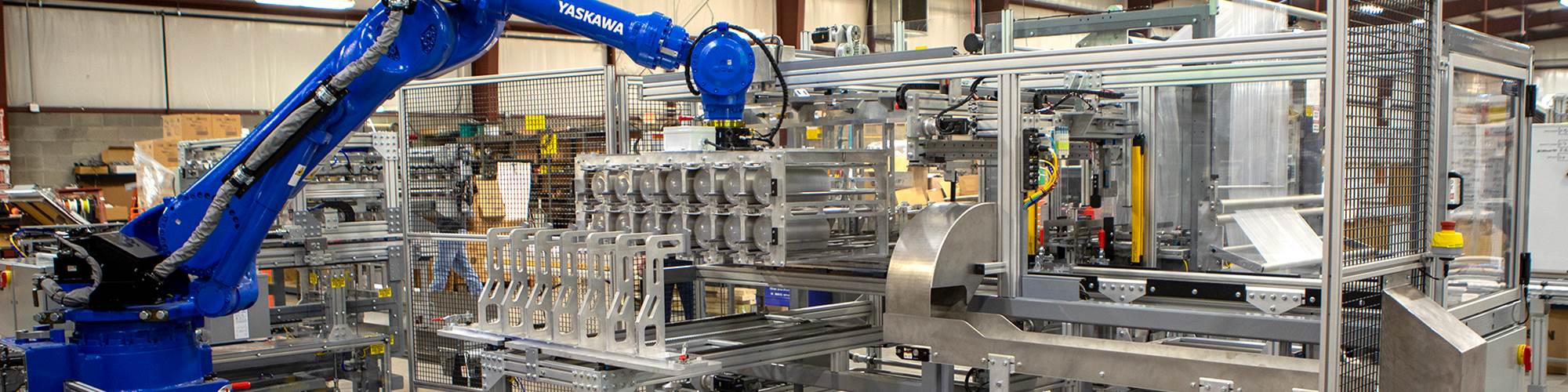

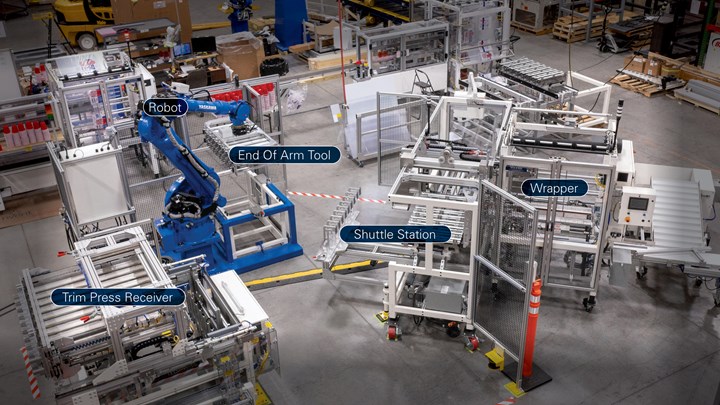

Photo shows various components of the new Mantis Robotic Trim Press Handler. (Photos: BMG)

Kurt Huelsman, president of NAS, calls the TPR the “core of the line.” As he explains, “Being able to cut into the ‘deck of cards’ of multiple lanes of product, separate them, and then contain them as they are pulled off the trim press while it is still running does not sound hard. But no one has ever done it effectively before. Mantis can handle products that have been relegated to non-servo eject because they are hard to handle, such as lids, which don’t nest well. Without the TPR, we have a nice robotic handler. With it, we have a non-servo-eject system that can handle products previously unable to be automated. The future of thermoforming is for automation to be built in, not simply an option or accessory.”

“The future of thermoforming is for automation to be built in, not simply an option or accessory.”

He adds, “Consistent and reliable separation of product on a continuously flowing, non-servo-eject trim press was the key to the development of Mantis. The design of the receiver, coupled with NAS’s robotic automation capabilities, brings a safe, productive and cost-effective solution to a historically very manual process.”

How it Works

As Jon Smalling, director of automation for NAS, explains, the TPR is butted up against the trim press. Raking and separating mechanisms within the TPR collect parts, which are presented to a six-axis robot equipped with product-matching, quick-change end-of-arm tooling (EOAT). The robot automatically transfers product to a Shuttle Station, which, after kicking out mis-trim or off-spec parts, integrates with downstream packaging functions that include wrapping, boxing, case packing, sealing and palletizing. Incorporating the robot allows the Mantis system to be very compact and configurable, making installation possible where floor space is limited or obstructed, BMG says.

Here, the Mantis robot transfers lids from the TPR to the shuttle.

BMG bills Mantis as configurable and adaptable. Explains Huelsman, “First of all, we can work with non-servo eject and servo trim presses from any supplier; the TPR interface designed for a BMG trim press would be different than for other brands. So there will be features to the TPR that will be unique to the particular trim press in terms of fixturing, attachments, etc. Adds Smalling, “The TPR takes up about the same space as operator interaction, if not less. Remember, a typical thermoforming plant has to allot space for three to five humans for pulling, separating and counting stacks of product. Our robot and shuttle station are completely reconfigurable. We’ve designed a system that can ‘dance around’ any existing footprint.”

Introduction of Mantis comes at a time when processors of all kinds are looking for automation solutions to improve efficiencies and mitigate ongoing worker shortages. Notes Bob Gordert, BMG’s v.p. sales for the Americas. “On the post-trim side, a very large percentage of our customers are requiring downstream automation to justify new thermoforming equipment in order to achieve their ROI and to mitigate exposure to workforce shortages.”

Close-up of Mantis robot with quick-change toll transferring lids that had been separated and stacked in TPR.

“We are excited about the first installation of the Mantis Robotic Trim Press Handler from NAS,” says Paul Phillips, BMG’s v.p. marketing. “The system will help thermoformers keep their lines running despite the labor shortages they are facing. The Mantis offers quick product changeovers and full product containment from the Trim Press to the bagger, all within a compact footprint with minimal human interaction. We fully expect the Mantis to provide themoformers with more uptime and reliable trim-press handling that grows with their business.”

“Our robot and shuttle station are completely reconfigurable. We’ve designed a system that can ‘dance around’ any existing footprint.”

Gordert says the partnership with its beta customer made sense because this particular thermoformer was committed to testing the TPR, its connection to the trim press (a non-BMG machine), and its ability to strip, rake and contain the product all the way through the robot tool. The installation went “smoothly, with minimal issues.” Huelsman says Mantis was up and running within two to three days and running around the clock within five days.

Optional features offered with the Mantis include remote monitoring for preventive maintenance, predictive maintenance, cycle-time analysis and other functions.

Mantis EOAT feeding lids to shuttle station.

The BMG Group is made up of Brown, Lyle, GN, Freeman (a supplier of thermoform tooling), NAS, and aXatronics. The latter is a certified Motoman Robotics strategic partner that focuses on creating high-level mechatronics process-engineered solutions for challenging processes in manufacturing. NAS, a 25-yr-old company, was acquired by BMG in 2016.

Related Content

Ingenuity Is Part of This Former’s Name, and in Its DNA

Plastic Ingenuity started in a garage in 1972 and through a commitment to developing best-in-class products stands today as one of the largest custom thermoformers in the world.

Read MoreMaking Gains in the Drain Game

AWD blends extrusion and thermoforming technologies with plenty of home-brewed equipment and processes to keep water away from where it isn’t supposed to be.

Read MoreThermoformed Container Keeps Battery Cells Safe

Despite last-minute design changes and other unexpected roadblocks, thermoformer TriEnda works with a key supplier on innovative reusable shipping container.

Read MoreAutomation in Thermoforming on the Rise

Equipment suppliers’ latest innovations exemplify this trend driven by factors such as labor shortages, higher-speed thermoformers and tighter quality control.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read More