Novel Fuel Systems Power Blow Molder’s Growth

Nano technology gives The Plastics Group a leg up on developing fuel systems for non-automotive applications

In an economy that still isn’t firing on all cylinders, you’re doing something right when you increase sales by roughly 30% from one year to the next. In the case of The Plastics Group (TPG), there are quite a few somethings contributing to this success, not the least of which is novel technology that gives TPG a leg up on developing fuel systems for non-automotive applications.

Not to be confused with a similarly named compounder in the Northeast, TPG (theplasticsgroup.net) is a Willowbrook, Ill.-based blow molder whose roots reach back to 1963. With plastics still in relative infancy, TPG was then focused on converting existing metal and wood products to blow molded applications. Through the use and development of new materials and process expertise, the Willowbrook operation established itself as a premier Midwest blow molder. In short order, it expanded into providing the automotive, large truck, office furniture, and portable sanitation equipment industries with a variety of products.

In the late 1990s, the company’s strategy was to provide highly engineered products and value-added services from advantageous geographic manufacturing locations, recalls Rich Ellis, vp of sales for TPG’s custom business unit. In 1997, the firm bought Borse Industries, a custom blow molder also located in Willowbrook. Borse was merged with Pawnee Rotational Molding, a custom rotomolder in Maple Plain, Minn., acquired a few years earlier.

This strategy continued in 1998 with the purchase of Wedco Molded Products, a custom and proprietary blow and rotational molding company in Boucherville, Que., and Fremont Plastics Products, a custom blow molder in Fremont, Ohio.

The approach started to shift a few years ago. The Quebec operation was relocated to TPG’s U.S. facilities in 2006. The next year, the rotational molding operation was sold, allowing TPG to focus all of its resources on its core competency of blow molding.

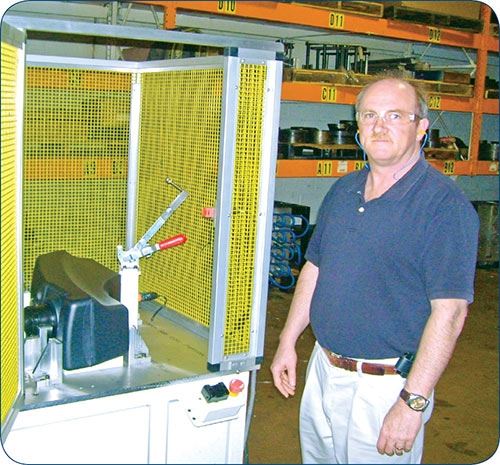

Today,TPG operates out of two facilities: a 170,000-ft² plant Willowbrook that employs more than 150 people; and a 200,000-ft² plant in Fremont that employs more than 250. Combined, TPG runs about 50 accumulator-head machines with shot sizes from 1 oz to 100 lb. Nine machines are capable of more than 50-lb shots. Most of the machines are Hartig’s, which are now part of the Davis-Standard family. TPG primarily runs HDPE, but also works extensively with ABS and PP, sometimes filled with glass, talc, or calcium carbonate.

TPG has both consumer and custom operations. The former consists primarily of jerry cans and drain pans that carry the Wedco name for products sold in Canada; and Briggs & Stratton for cans sold in the U.S. The custom business is divided into four subsegments: fuel systems, structural systems, seating systems, and fluid-management systems.

One of TPG’s major successes was launched about 10 years ago, when it worked with a major bedding manufacturer and retailer on a blow molded mattress foundation that replaced a series of vinyl extruded parts parts with metal brackets and fastners that tended to rattle. “This part is made of HDPE and requires no fasteners,” Ellis states. “It’s structurally sound and has male and female joints that are molded in.

“Regardless of the project, we try to incorporate as many features into the product during the molding process itself,” Ellis adds. “Our objective is to create value, and a system for our customers that will allow them to reduce their number of components and suppliers so they can get product to market faster and reduce the amount of floor space they devote to assembly.

“What sets us apart is our unique machine capabilities, both in the number of machines we have and the size range. That, plus the depth and breadth of our technical experience and our vast capabilities, including ISO registered quality systems, program management, product design, tooling design (actual moldmaking is outsourced), secondary systems design, automation, and more.

Ellis continues: “We operate on a ‘one-stop shopping’ premise, so if post-molding operations are required, we do it. This includes robotic finishing, drilling, assembly, and labeling. We have significant secondary, assembly, and pack-out operations. We maintain a significant amount of warehouse space, so we’ll carry inventory for our customers when necessary.”

NANO-TECH PROVIDES AN EDGE

TPG is also a major player in seating components for a variety of industries, providing seat backs, pans and shells. Large structural panels are another of TPG’s strategic market segment, notably panels for portable toilets. But perhaps the biggest reason for a healthy bump in sales from this year to last can be traced to TPG’s expertise in non-automotive fuel systems. Clearly, when you make more than 6.4 million fuel tanks and systems in a year you have developed a certain degree of expertise in the area.

TPG has made fuel tanks and systems for non-automotive applications for 20+ years. Its line of gas cans helped the molder develop the know how to design cost-efficient fuel tanks and systems that are certified by UL, CSA, EPA, USCG, and CARB.

“We started seeing an uptick in order volume from both existing and new customers for fuel-systems beginning last year,” notes Ellis. Those orders were in preparation for new emissions regulations that TPG had a solution for covering small off-highway engines that kicked in this January. The new rules call for about 35% lower hydrocarbon emissions from small engines.

The fuel systems affected by the regulations are used in a wide range of non-automotive applications, including ATVs, snowmobiles, riding and push lawnmowers, generators, power washers, and snow blowers.

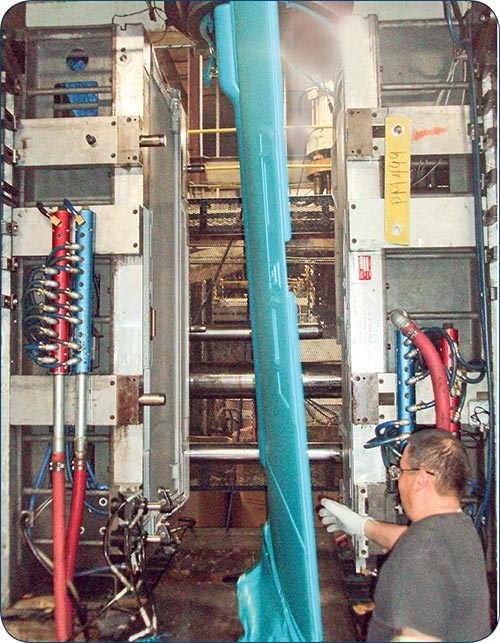

TPG’s solution is a single-layer tank processed using a proprietary nano-fortified HDPE furnished by an unidentifed supplier that offers barrier properties comparable to multi-layer structures and better than post-mold fluorination at lower cost.

TPG began working on this technology more than 10 years ago. The molder employed a number of engineers that had experienced the same environmental regulatory shift while working in the automotive fuel tank industry and had seen firsthand the evolution from monolayer to chemical barrier treatment (fluoroination and sulfonation) to multi-layer solutions.

TPG determined early in the process that the chemical barrier methods did not provide a long-term barrier solution, due mainly to the high cost. And it decided that the investment required for multi-layer technology could not be justified for the variety of tank sizes and lower volume production runs that the off-highway fuel tanks business required.

The search for an alternative began with nylon additives, and then a chance meeting at a technical seminar led to the discovery of a university in Israel that was working on a nano-clay additive that could provide hydrocarbon barrier properties to HDPE. The final solution was a nano-clay formulation, along with a lot of processing development. “It took us a lot of time and money to find the right material blend and develop the process window and ability to test for the barrier presence, but compared to the millions we would have spent on replacing all our machines, it has proven to be a great decision,” recalls Ellis.

The material is made for TPG on an exclusive basis, and Ellis did not delve into the particulars. Moreover, TPG has extrusion capacity at its Fremont facility where it can produce formulations for specific customer applications.

TPG is owned by members of its management team and private equity investors. While private equity conjures up images of cost-cutting and relentless bottom-line management in the minds of many, Ellis is quick to note that his ownership has a long-term view of things. “We were ready for the new emissions standards before most of our competition because, even during the recession, we continued with our R&D efforts,” he says. “So when our customers were ready to move forward, we were more than ready to provide them a solution.”

Related Content

First Water Bottles With Ultrathin Glass Coating

Long used for sensitive juices and carbonated soft drinks, KHS Freshsafe PET Plasmax vapor-deposited glass coating is now providing freshness and flavor protection for PET mineral water bottles.

Read MoreProcessing Megatrends Drive New Product Developments at NPE2024

It’s all about sustainability and the circular economy, and it will be on display in Orlando across all the major processes. But there will be plenty to see in automation, AI and machine learning as well.

Read MoreGet Color Changes Right In Extrusion Blow Molding

Follow these best practices to minimize loss of time, material and labor during color changes in molding containers from bottles to jerrycans. The authors explore what this means for each step of the process, from raw-material infeed to handling and reprocessing tails and trim.

Read MoreHow Inline Vision Inspection Can Minimize Scrap in Molding

Once viewed by injection and blow molders as a necessary evil, machine vision technology today can continuously monitor and improve production while reducing costs.

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read More