Novel LLDPEs Enable Films that Are 'Ahead of Their Time'

ExxonMobil’s new Exceed XP 7 series boasts remarkable mechanical performance combined with low density and fractional melt index.

Levels of performance “never seen before” are claimed for a series of hexene LLDPE film resins that ExxonMobil unveiled last fall. Produced with a proprietary metallocene catalyst, Exceed XP 7021 and 7052 are said to deliver remarkable mechanical performance with a combination of low density and fractional melt index that enable the production of innovative new film structures not previously possible. This potential covers a range ofapplications, including moisture-barrier construction, stretch-hood, collation shrink and greenhouse films.

The combination of attributes that reportedly have not been previously available in a single resin include high levels of elasticity and holding force, puncture energy, and dart impact resistance. (All images: ExxonMobil)

The combination of attributes that reportedly have not been previously available in a single resin includes high levels of elasticity and holding force, puncture energy (up to 2.3 J/mil) and dart impact resistance (up to 900 g for a 25.4-micron film). ExxonMobil also says that XP 7021 and XP 7052 offer a combination of fractional MI and low density (0.911- 0.912 g/cm³) that has also not been commercially available before, resulting in enhanced bubble stability and creating opportunities for increased output.

The company has been working closely with processors to develop new film formulations that many in the industry say are ahead of their time, according to Tom Miller, Exceed XP 7 PE product manager.

Among these collaborators is Tex-Trude, a 70-yr-old privately held company based in Channelview, Tex., where it runs three main divisions—for PE blown film, PVC profile extrusion and flexible vinyl compounding—out of one manufacturing plant.

Charlie Nettles III, Tex-Trude’s president, says the company is using Exceed XP 7 in new formulations for vapor-barrier construction films designed for use under concrete slabs, as well as stretch-hood packaging films. Based on the excellent results achieved with these products, Nettles anticipates that within a few months, Tex-Trude will use XP 7 in other film-packaging applications, such as lawn & garden, mulch and other chemicals.

Improved Vapor Barrier & Stretch Hood Films

Tex-Trude extrudes vapor-barrier films in thicknesses from 10 to 20 mils. Nettles noted that the material provides a huge improvement in dart-drop impact consistency—90+% compared with 50-60% achieved from previously used resins.

Tex-Trude has been adding new equipment and expects to enter new markets for its stretch-hood films that might not have been possible without the new resin.

Nettles also noted a significant improvement in bubble stability. As a result, Tex-Trude replaced a blend of fractional-melt LDPE and a metallocene hexene LLDPE with XP 7 blended as the main component with a butene LLDPE. This has led the firm to switch all of its Xtreme Vapor Barrier product line to the XP 7 formulation. Films in this product line far exceed the ASTM E1745 standards for water-vapor barriers and raise the bar for others in the market, Tex-Trude says. (See Jim Nettles and his team discuss new high-performance vapor-barrier films at https://short.ptonline.com/construct.)

Tex-Trude is using Exceed XP 7 to produce 10-mil to 20-mil monolyayer vapor-barrier construction films specifically designed for use under concrete slabs.

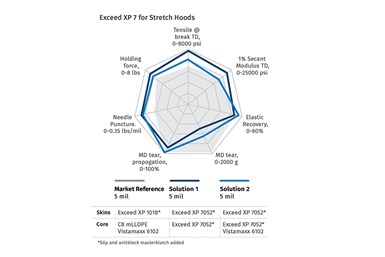

Tex-Trude is also developing three-layer, 2-mil to 6-mil stretch hood films in which XP 7 as the main component is blended with other high-performance metallocene hexene LLDPEs. These films provide the snap -back and strength required by this market. Preliminary results are excellent, according to Nettles, with further trials on the way. The company focuses its trials typically on producing mid-gauge films to determine performance prior to producing thinner or thicker films.

Performance achieved in these film trials include significant improvements in elasticity, dart impact strength, and puncture resistance from a tear perspective that prevents holes forming over corners of pallets during application and transportation. Less “tiger striping” also has been shown. (See the Tex-Trude team discuss new stretch-hood films at https://short.ptonline.com/stretchhood.)

Nettles says Tex-Trude has been adding new equipment and expects to enter new markets for its stretch-hood films that may not have been possible without the new resin.

“Films that exhibit MD and TD shrinkage at low temperatures, and can be processed on traditional blown film lines, are a rarity in the market.”

Under development at Tex-Trude are three-layer 2-mil to 6-mil stretch-hood films in which XP 7 is the main component.

Other Promising Applications

ExxonMobil has collaborations underway to develop formulations with Exceed XP 7 resins for other applications. According to Miller, these include:

• Collation shrink films that shrink at low temperatures and offer potential energy savings. XP 7 resins enable high shrink speeds at temperatures as low as 120 C/248 F. Such films can protect sensitive products from excessive heat. The removal of cardboard trays is possible in many applications, according to Miller. “Films that exhibit MD and TD shrinkage at low temperatures, and can be processed on traditional blown film lines, are a rarity in the market,” he adds.

• Primary packaging films with low seal-initiation temperatures for fast sealing. Films made with XP 7 can help seal packages at low temperatures without blocking issues. Processors can reduce antiblock levels to improve coefficient-of-friction control and optical properties for better brand promotion. These resins reportedly also enhance packaging toughness with best-in-class flex-crack resistance and extreme dart-impact and puncture resistance, while offering good optical properties.

Collation shrink film is another major application for Exceed XP7 resins, as are primary packaging films and greenhouse films.

Says Miller, “Flex-crack resistance is so high, tests undertaken by ExxonMobil resulted in an average of 1 hole/10,000 cycles. The combination of fractional MI and a 0.912 g/cm³ density helps prevent seal thinning without the addition of LDPE when compared with conventional sealing resins.”

• Greenhouse films with remarkable softness and clarity combined with extreme dart and puncture resistance. Greenhouse films that are tough, clear and soft can now be fabricated with XP 7, producing films with reduced risk of failure and premature breakage during installation and use.

“Films made with these new grades offer farmers the opportunity to enjoy longer and better growing conditions for potentially higher crop yields, helping to meet the growing population’s need for food,” says Miller.

Related Content

The Fundamentals of Polyethylene – Part 1: The Basics

You would think we’d know all there is to know about a material that was commercialized 80 years ago. Not so for polyethylene. Let’s start by brushing up on the basics.

Read MorePrices Up for PE, PP, PS, Flat for PVC, PET

Trajectory is generally flat-to-down for all commodity resins.

Read MorePrices Flat-to-Down for All Volume Resins

This month’s resin pricing report includes PT’s quarterly check-in on select engineering resins, including nylon 6 and 66.

Read MorePolyethylene Fundamentals – Part 4: Failed HDPE Case Study

Injection molders of small fuel tanks learned the hard way that a very small difference in density — 0.6% — could make a large difference in PE stress-crack resistance.

Read MoreRead Next

The Fundamentals of Polyethylene – Part 2: Density and Molecular Weight

PE properties can be adjusted either by changing the molecular weight or by altering the density. While this increases the possible combinations of properties, it also requires that the specification for the material be precise.

Read MoreHot Half-Dozen Applications Driving Developments in PE

Sustainability, consumer convenience, and evolving e-commerce packaging are driving new advances in polyethylene.

Read MoreThe Fundamentals of Polyethylene – Part 1: The Basics

You would think we’d know all there is to know about a material that was commercialized 80 years ago. Not so for polyethylene. Let’s start by brushing up on the basics.

Read More