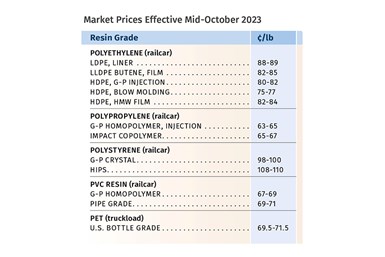

Prices Up for PE, PP, PS, Flat for PVC, PET

Trajectory is generally flat-to-down for all commodity resins.

Prices of the five commodity resins going into October were a mixed bag, owing to factors such as supply/demand issues, seemingly temporary spikes in some feedstocks due to primarily to unplanned production shutdowns and prebuying activity as protection to the hurricane season ending midmonth. In the case of PE and PP, unexpected outages in both feedstock and resin production resulted in some force majeure declarations. This apparently translated to drawdowns in suppliers’ PE and PP inventories which gave them the momentum to push through increases. Both PE and PP suppliers have increased operating rates primarily to serve the exports markets.

These are the views of purchasing consultants from Resin Technology Inc. (RTi), senior analysts from Houston-based PetroChemWire (PCW), CEO Michael Greenberg of The Plastics Exchange, and Scott Newell, executive v.p. polyolefins at distributor/compounder Spartan Polymers.

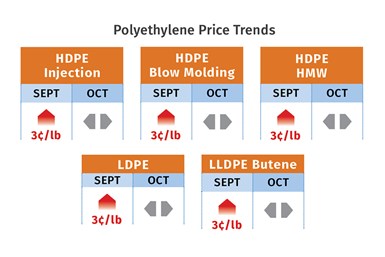

PE Prices Up, Then Flat

Polyethylene prices moved up another 3¢ in September, following the August increase, and suppliers had a similar price initiative for October, according to David Barry, PCW’s associate director for PE, PP, and PS, Robin Chesshier, RTi’s v.p. of PE, PS, and nylon 6 markets, and The Plastic Exchange’s CEO Michael Greenberg. Generally, these sources venture that prices in the October-November time frame are likely to be flat-to-down.

RTi’s Chesshier attributes the increases to a very strong exports market as international feedstock prices had risen and also to an uptick in domestic demand which appeared to be partially attributed to prebuying due to hurricane season. Reports The Plastic Exchange’s Greenberg, “The alternative export demand, which has been approaching 50% of all domestic PE, has helped producers secure consecutive 3¢/lb price increases in August and September. As prices rise, it has been pulling domestic buyers back to the market as they compete to restock their heavily drawn down inventories,” Greenberg reports .

All three sources also noted two ongoing force majeures but also that more significant new capacity was being brought on stream by Baystar, Nova and Shell. PCW’s Barry points out that suppliers have increased export prices by about 7¢/lb, this while there were reports of softer demand in international markets as well. This was forecast to continue into 2024.

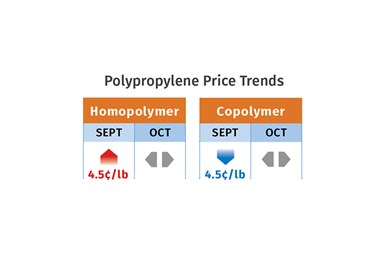

PP Prices Up for Now

Polypropylene prices moved up 4.5¢/lb in September in step with propylene monomer, primarily attributed to unplanned and planned monomer production issues, according to PCW’s Barry, Spartan Polymers’ Newell and The Plastic Exchange’s Greenberg. This after dropping 0.5¢/lb in August for a decline of 19.5¢/pound since first quarter. Prices were expected to be flat in October, but unclear going into this month and next, and pretty much dependent on the monomer’s price stability.

The issue is monomer inventory tightness which may last for another couple of months. Moreover, on-purpose propylene suppliers have PDH units scheduled for turnarounds in January, and are actively looking for propylene imports, according to PCW’s Barry, who describes the scenario as a pretty dynamic supply situation. This not an issue for PP where demand has continued to struggle, despite an uptick in demand in August that was largely attributed to prebuying activity, notes Spartan Polymers’ Newell.

PP spot prices were flat to higher, despite an unexciting demand outlook for fourth quarter, according to Barry and The Plastic Exchange’s Greenberg who reported, “Polypropylene trading stayed healthy to close out September; demand picked up while monomer prices rallied as buyers sought to procure additional material ahead of a potential October increase. The supply/demand dynamic for PP is better balanced, especially as producers have begun to tap the export market with more fervor.” Meanwhile, Barry reports that Braskem confirmed the extended idling of one of the two PP trains at its Marcus Hook, Pennsylvania, facility, representing about 450 million pound/year.

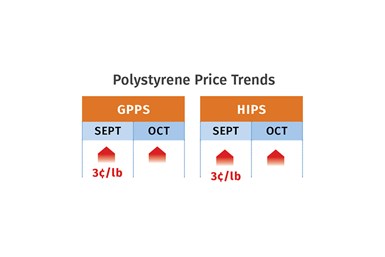

PS Prices Spike, Then Drop?

Polystyrene prices rose by 3¢/pound in September, having risen by 3¢/lb in August, after dropping a total of 9¢/lb the two previous months, according to PCW’s Barry and RTi’s Chesshier. Moreover, PS prices in October were forecast to increase 8¢/lb, reflecting increases of a 7¢/lb in October benzene contracts that settled at $4/gallon and a 1¢/lb hike in ethylene. According to Barry, the implied styrene cost based on a 70% benzene, 30% ethylene spot formula jumped up 9.8¢/lb within a four-week period going into October.

Noting that there was a short-squeeze of domestic benzene supply, Barry says, “I think it will be a tough sell for suppliers to get all 8¢/lb, as the majority of PS market operates on feedstock cost formulation. There is not much activity in the secondary market and imports are down 24% from September 2022 year-to-date.” Similarly, Chesshier ventures that PS prices this month and December will see a gradual decline as benzene is currently overvalued.

PVC Prices Flat

PVC prices were a rollover in September, despite suppliers aiming for a 4¢/pound increase which they hoped would at least partially be implemented that month, following the August 2¢/pound increase, according to Paul Pavlov, RTi’s v.p. of PP and PVC and PCW’s senior editor Donna Todd. The latter reported that an industry pundit who forecast a partial 1¢/lb increase for September, changed the forecast to flat. It appears that suppliers aimed to remedy the situation with Westlake, Shintech and Formosa restating their increase to a 2¢/lb for October. OxyVinyls was missing, but expected to follow suit.

Pavlov notes that the supply situation improved significantly between second and third quarter, with days of supplier inventories now at 14-to-16 days, and domestic demand not as strong as expected. Also, more new capacity was being brought on stream by Formosa though a debottleneck. “We’re exporting more PVC this year than in 2022,” Pavlov says.

PET Prices Flat, Then Down

PET prices rolled over in September (based on raw material formulation contracts), having moved up in August by 3¢/lb, and prices may have possibly peaked this year, according to Mark Kallman RTi’s v.p. of PVC, PET and engineering resins. Moreover, he sees the potential for a 1¢ to 2¢/lb, give or take for October-November. “This remains a well-supplied market with substantial competitive priced imports. So far, imports account for a $250 million/lb versus $40 million/lb that primarily go to Canada.”

In addition, recent major industry news involves the pausing of construction to the 2.6-million lb/yr PET plant in Corpus Christi, Texas, with partners Alpek, Indorama and FENC (Far Eastern New Century). It was originally scheduled to start up in 2025. Construction costs, interest rates and labor shortages are factors.

Related Content

Fundamentals of Polyethylene – Part 3: Field Failures

Polyethylene parts can fail when an inappropriate density is selected. Let’s look at some examples and examine what happened and why.

Read MoreCommodity Resin Prices Flat to Lower

Major price correction looms for PP, and lower prices are projected for PE, PS, PVC and PET.

Read MoreFirst Quarter Looks Mostly Flat for Resin Prices

Temporary upward blips don't indicate any sustained movement in the near term.

Read MoreFundamentals of Polyethylene – Part 6: PE Performance

Don’t assume you know everything there is to know about PE because it’s been around so long. Here is yet another example of how the performance of PE is influenced by molecular weight and density.

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read More