Now LDS Electronic Circuitry Is Colorable

Laser direct structuring (LDS) is a powerful technology for adding electrical circuit paths to plastics electronic products such as mobile phone and notebook antennas or molded interconnect devices (MIDs). But up to now, LDS-ready plastics were limited to black.

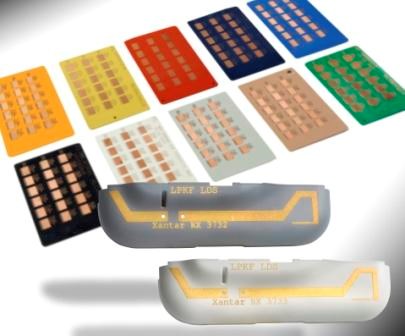

Laser direct structuring (LDS) is a powerful technology for adding electrical circuit paths to plastics electronic products such as mobile phone and notebook antennas or molded interconnect devices (MIDs). But up to now, LDS-ready plastics were limited to black. Now two suppliers have come up with customcolorable materials for LDS. SABIC Innovative Plastics, Pittsfield, Mass., was the first, with its LNP Thermocomp NX11302 (photo), a specialty PC/ABS for applications like LEDs and connectors. It was soon followed by two grades from Mitsubishi Engineering Plastics (MEP America, N.Y.C.). It brought out Xantar LDS 3723 PC/ABS for mobile-phone housings and other telecom devices, as well as Xantar LDS 3733 PC for antennas.

LDS is made possible by formulation technology from LPKF Laser & Electronics AG in Germany (U.S. office in Tualatin, Ore.). Its approach involves compounding a special additive into the plastic. Then, specialized lasers are used to scribe the circuit layout onto the plastic part. The laser light activates the additive (an organic metal complex) so that it will accept electroplated copper and also roughens the plastic surface to help the plating adhere.

Related Content

-

Cobot Takeout System for Shuttle Machines

NPE2024: Proco Machinery upgrades its Robopik bottle takeout system for shuttle blow molders with the addition of a collaborative robot.

-

Thin Wall Ultrasonic Bonding Technology for Automotive

NPE2024: Dukane’s new Ultrasonic Thin Wall welding system is well suited for welding applications of PP to PP TD25 painted parts.

-

Digital Signal Processor Power Supply for Ultrasonic Welders

NPE2024: Sonics launches Model DX800 for its DX Series OEM DSP Power Supply.