New Machines & Processes For Macro to Micro Parts

In late April, Wittmann Battenfeld GmbH hosted around 1100 visitors at its headquarters plant in Kottingbrunn, Austria, for a comprehensive demonstration of its latest injection molding technologies.

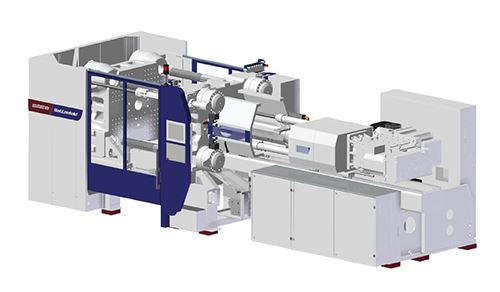

In late April, Wittmann Battenfeld GmbH hosted around 1100 visitors at its headquarters plant in Kottingbrunn, Austria, for a comprehensive demonstration of its latest injection molding technologies. The Competence Days event featured 17 machine exhibits spotlighting new developments in hydraulic, electric, and hybrid machines ranging from large tonnage to micro-molding. There were also new developments in Wittmann’s auxiliary equipment (see Keeping Up with Technology). Wittmann’s U.S. operations are based in Torrington, Conn. For upcoming expansion plans there, see Starting Up.

LARGE PRESSES DEBUT

The machine demonstrations took place in a brand-new building that adds 32,300 ft² dedicated to assembly of MacroPower large machines. That’s where the first two units of the company’s largest standard size—1600 metric tons—will be built this year (one of them will be displayed at the K 2013 show in Düsseldorf this Fall). The MacroPower 1600 completes the line as currently planned.

Shown for the first time at the open house was a 450-m.t. model of the new MacroPower E hybrid, a press designed as the most energy-efficient and cost-effective step up from the company’s EcoPower all-electric line, which tops off at 300 m.t. The new hybrid retains the MacroPower two-platen hydraulic clamp with a variable-volume pump driven by electric servo motor for maximum efficiency. That is paired with an electric screw drive and injection unit capable of speeds up to 450 mm/sec. Ejection is also electric servo powered. The press was demonstrated molding packaging with a 64-cavity mold.

Other news in the MacroPower line is the expansion of the firm’s Cellmould structural-foam technology with direct gas injection to barrel sizes up to 105 mm diam.

Although not shown at the event, company sources revealed that last year it built a special 1000-m.t. MacroPower system for a Norwegian molder to make 88-lb PP parts for an agricultural application. Since the parts exceeded the plasticating capacity of the machine, Wittmann Battenfeld added a transfer pot that could hold three times the barrel capacity. In operation, the transfer pot is filled three times with the maximum plastication capacity before being emptied by a plunger.

Wittmann Battenfeld has upgraded the payload capacity of its W832 robot for presses of 400 to 800 m.t. It now handles up to 55 lb, a 20% increase, and an optional configuration can take up to 77 lb.

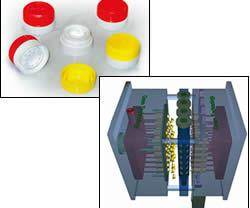

MICRO-MOLDING NEWS

At the opposite end of the size range, Wittmann Battenfeld announced a new process capability for its all-electric MicroPower micro-injection machines of 5 and 15 tons. This Hi-Q Shaping process is a high-precision injection-compression technique adapted for tiny parts such as lenses with even tinier micro-features. Microfluidic “lab-on-a-chip” devices and parts with nanostructured surfaces are also potential applications. What distinguishes Hi-Q Shaping from standard injection-compression is the continuous regulation of the process in order to achieve constant pressure on the part as it shrinks. The process is adapted to the PVT curve of the material.

Hi-Q shaping involves continuous monitoring of cavity pressure and cavity wall temperature in order to continuously adjust the compression process. The actual compression stroke is 0.4 to 0.6 mm, depending on the mold. Hi-Q Shaping is said to achieve much lower stresses in the material as well as shorter cycles than are possible with variotherm (heat/cool) processes. The process was demonstrated molding a PC lens with Fresnel ridges for a cell phone.

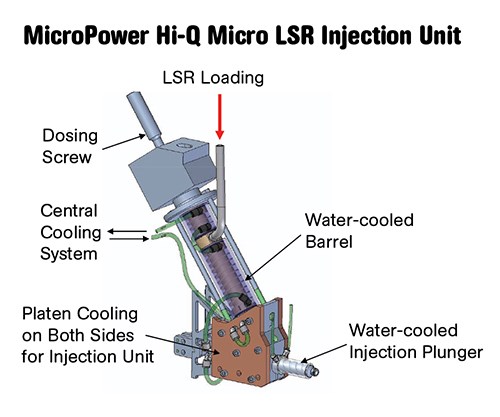

Wittmann Battenfeld also unveiled a version called Hi-Q LSR for liquid silicone rubber micro parts. It requires a special injection unit with a water-cooled barrel for the dosing screw and a water-cooled injection plunger. Small (1-liter) LSR cartridges can be mounted inside the machine cabinet, maintaining a self-contained clean-room system. Hi-Q LSR was demonstrated on a 5-ton MicroPower system molding 0.75-mg medical implants in two cavities. The modular MicroPower system can be converted between thermoplastic and LSR in about 2 hr.

HIGH-SPEED ELECTRIC MOLDING

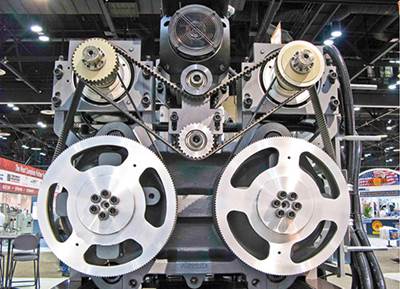

Moving a bit up the size scale, Wittmann Battenfeld introduced its EcoPower Xpress system as part of its continuing development of ever faster all-electric molding machines. Demonstrated on a 180-m.t. press, it utilizes a special injection unit with a rack and pinion instead of ballscrews. It is said to be capable of 450 mm/sec injection, competitive with an hydraulic accumulator.

Such high-speed molding requires an equally speedy robot, so this demonstration afforded an opportunity to show off the company’s new booster axis for side-entry robots. Called “All-Wheel Drive,” it utilizes two synchronized servo motors to achieve mold-open times of only 0.3 sec. Two small motors are said to be more economical than one larger one and they have faster acceleration and cause less wear on the indexing belt. This development was demonstrated on the a new model W937 2-drive robot.

MORE PROCESS INNOVATIONS

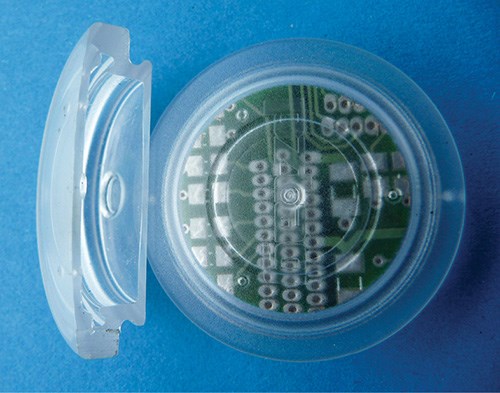

Another novelty at the open house was a process for in-mold internal welding (IMIW). It provides a means of encapsulating sensitive electronics such as RFID chips while protecting them from damage from heat or pressure during molding. IMIW was developed by Barkley Plastics, a British molder and moldmaker.

As demonstrated on an EcoPower 110-m.t. press, the process involves molding two halves of the encapsulating shell on opposite mold faces. When the mold opens, the mold plate slides to the side and a robot inserts the electronics in one shell half. When the mold closes, the two shell halves are brought together and the same material (polycarbonate in this case) is injected between the shell halves, providing a water- and gas-tight seal. When the mold opens, the same robot removes the finished part.

As compared with other processes, such as JSW’s Die-Slide molding, there are no external ridges or welding beads joining the two parts, providing a cosmetic seal and requiring no downstream finishing.

On an EcoPower 180-m.t. machine, Wittmann Battenfeld showed off increasing sophistication in in-mold labeling (IML). PLA bioresin bank cards were molded in four cavities with paper labels on both sides of each card. The process required injection of the PLA through one of the labels.

Another crowd-pleasing demonstration utilized the firm’s HM ServoPower hydraulic press with servo-electric pump drive and Airmould gas-injection system. The feat was molding a hockey stick of glass-filled PP in an oversized mold with a gas channel 1300-mm long.

Related Content

Internal Gas Pressure Molding Offers Sustainability Benefits

Wittmann Battenfeld says its upgraded Airmould 4.0 technology, which features a more compact footprint, saves material and cycle time — thereby also cutting energy use.

Read MoreCompletely Connected Molding

NPE2024: Medical, inmold labeling, core-back molding and Industry 4.0 technologies on display at Shibaura’s booth.

Read MoreFakuma 2023: Wittmann Battenfeld Expands All-Electric Line, Direct-Current Capabilities

Wittmann Battenfeld will introduce the new EcoPower B8X injection molding machine line and show direct current as an energy source for a concept machine that will power its own robot.

Read MoreRead Next

NPE: New Machines Exhibit Sophisticated Molding Demos

More speed, more power, more precision, and more automated functions accomplished in and out of the mold. That’s exactly what injection machinery suppliers were offering at NPE2012.

Read MoreIn-Mold Assembly: The New Frontier for Multi-Shot Molding

The drive to eliminate secondary operations is pushing multi-shot injection molding a step farther—toward assembling separate components in the tool via snap-fits, welding, and co-molding of incompatible materials.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read More