Plastics Processing Activity Near Flat in February

The month proved to not be all dark, cold, and gloomy after all, at least when it comes to processing activity.

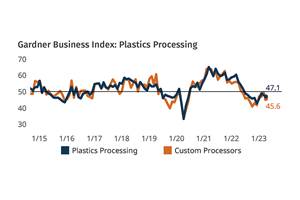

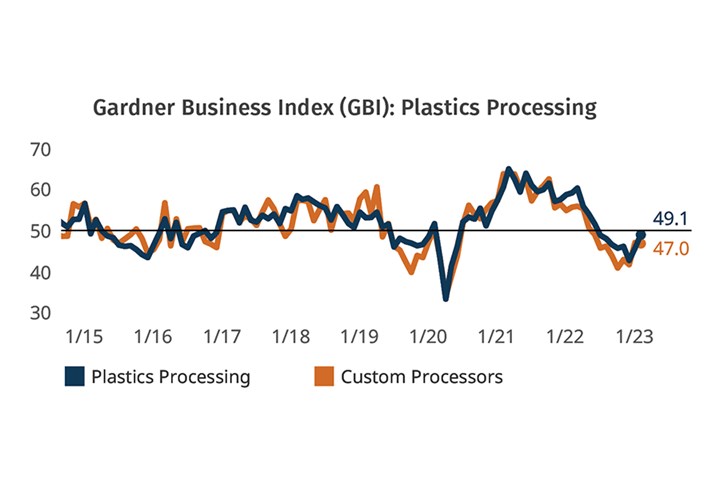

While contracting for the eighth month straight, the rate of contraction of plastics processing activity slowed in February, continuing a trend that began in January. The Gardner Business Index for Plastics Processing closed February up four points, to 49.1, landing close to July’s index that launched the eight-month contractionary period. The index is based on survey responses from subscribers to Plastics Technology. Indices above 50 signal growth; below 50, contraction.

FIG 1 Plastics processing activity contracted again in February for both custom processing and total processing, but the latter inched closer to flat.

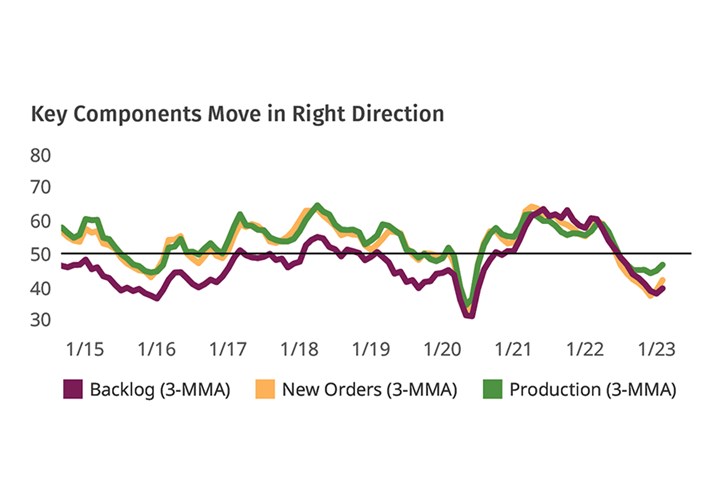

The GBI sub-index for new orders appeared to be leading the way — still contracting, but at a slower rate in February. As expected, production activity and backlogs followed suit. February export and employment activity stayed about the same as last month, both still contracting, with employment inching ever-so-close to flat, where it has hovered for five months. There was no pressure on supplier deliveries in February, reinforcing that any uptick in plastics activity is not going to stress the system. In fact, supplier deliveries that have been lengthening at a slowed rate for months threatened to shorten in February.

FIG 2 Drivers of plastics processing activity contracted at slower rates in February.

If the past 12-month supplier deliveries trend continues into March, there will be a shortening of supplier delivery times for the first time in three years. The supplier deliveries trend also suggests supply-chain issues that artificially lengthened supplier deliveries for months have resolved or have otherwise lost their impact. The GBI Plastics Processing Index and component activity are encouraging, but far from “on fire,” so cautious optimism is recommended. Overall business activity for custom processing stayed about the same, contracting to a greater degree than total plastics processing in February.

EDITOR’S NOTE: Finding reliable and relevant data to help guide your business is always important, but especially so during challenging economic times. For this reason, the GBI Plastics Processing Index serves as a great tool for making data-driven decisions. Thank you to everyone who has previously completed GBI surveys. Your participation helped increased response in 2021-2022, making the GBI better than ever because of your involvement. Thank you for your time and efforts and for trusting us to provide you with the latest industry and business insights both in the past and in the future.

If you are a North American plastics processor and would like to participate in this research, click here to begin the process by subscribing free to Plastics Technology magazine.

ABOUT THE AUTHOR: Jan Schafer is director of market research for Gardner Business Media, parent company of both Plastics Technology magazine and Gardner Intelligence. She has led research and analysis in several industries for over 30 years. She has a BA in psychology from Purdue University and MBA from Indiana University. She credits Procter & Gamble for 15 years of the best business education. Contact: (513) 527-8952; jschafer@gardnerweb.com.

Related Content

Plastics Processing Continued Contraction in April

Despite some index components accelerating and others leveling off, April spelled contraction for overall plastics processing activity.

Read MoreNPE2024 and the Economy: What PLASTICS' Pineda Has to Say

PLASTICS Chief Economist Perc Pineda shares his thoughts on the economic conditions that will shape the industry.

Read MorePlastics Processing Index Remains Virtually Unchanged

Future business indicators rose again this month, but other inputs changed only slightly.

Read MorePlastics Index Shows Fourth Consecutive Monthly Gain

December reading hints at slowing contraction as plastics industry outlook improves

Read MoreRead Next

Beyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read More