Processing Takes a Dip in June

Plastics activity took a relatively big downturn in June, ending at a low for the year and lower than the same month a year ago.

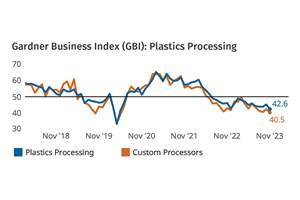

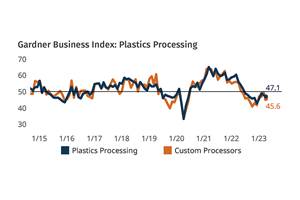

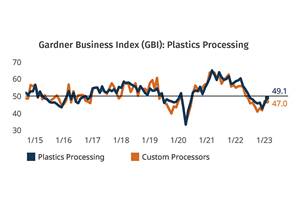

The Gardner Business Index (GBI): Plastics Processing (44.5) dropped 2.3 points in June relative to May’s 47.8. The index is based on survey responses from subscribers to Plastics Technology. Indices above 50 signal growth; below 50, contraction.

The story in plastics processing has been consistent with other manufacturing segments for the past few months, reinforcing the belief that the downturn is “real.”

It appears that accelerated contraction in new orders and backlog primarily drove accelerated contraction in June’s plastics index. Production also contracted, albeit to a lesser degree.

Contraction in exports and employment stayed relatively steady. Supplier deliveries lengthened at a minimally slower rate in June, marking the first time this year that direction changed. It is surprising that we did not see a slowing sooner in light of accelerated contraction in new orders for a couple months now. Sentiment about future business remained positive, but declining.

The index for custom processors dropped 1.1 points in June, following a 3.4 decline in May.

FIG 1 Plastics processing overall contracted appreciably in June, while custom processing activity also contracted at a faster clip.

New orders and backlogs, in particular, contracted at accelerated rates in June, driving drops in overall plastics indices.

About the Author

Jan Schafer

Jan Schafer is director of market research for Gardner Business Media, parent company of both Plastics Technology magazine and Gardner Intelligence. She has led research and analysis in several industries for over 30 years. She earned a bachelor’s degree in psychology from Purdue University and an MBA from Indiana University. She credits Procter & Gamble for 15 years of the best business education. Contact: 513-527-8952; jschafer@gardnerweb.com.

Related Content

Plastics Processing Activity Drops in November

The drop in plastics activity appears to be driven by a return to accelerated contraction for three closely connected components — new orders, production and backlog.

Read MorePlastics Processing Continued Contraction in April

Despite some index components accelerating and others leveling off, April spelled contraction for overall plastics processing activity.

Read MorePlastics Processing Activity Near Flat in February

The month proved to not be all dark, cold, and gloomy after all, at least when it comes to processing activity.

Read MoreProcessing Megatrends Drive New Product Developments at NPE2024

It’s all about sustainability and the circular economy, and it will be on display in Orlando across all the major processes. But there will be plenty to see in automation, AI and machine learning as well.

Read MoreRead Next

Making the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More