Profile Extruder Sees the Light

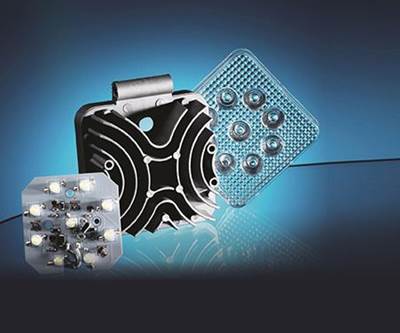

Rotuba exited the sheet business to focus on custom profiles for LED light fixtures. It now ranks as North America’s leading profile extruder in this burgeoning market.

The LED market is expanding rapidly as lighting OEMs respond to the ever-increasing push for energy efficiency. All you need to confirm that trend is walk into your home-goods store to buy light bulbs. Materials suppliers, meantime, are busy developing new grades for processors involved in this business (see June’s cover story).

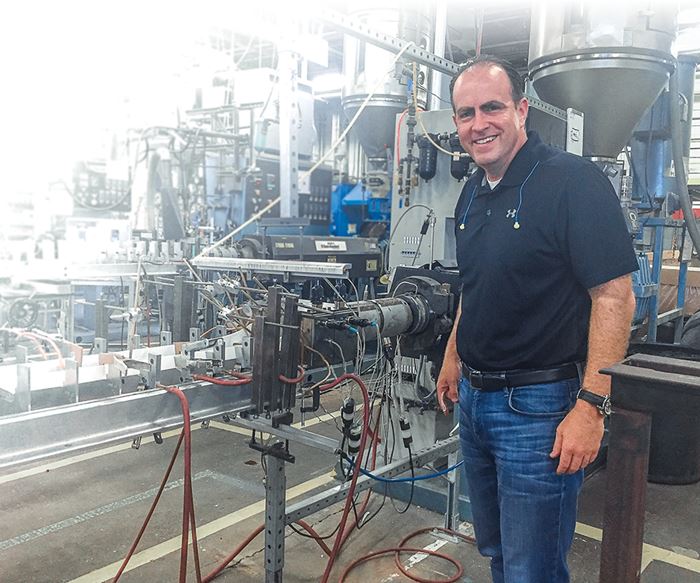

This growth notwithstanding, LED lighting is considered a somewhat new and still-developing industry. But Adam Bell saw trends developing ahead of the pack and reconfigured his company to capitalize on it. Perhaps he has an LED-illuminated crystal ball?

If he does, it was not in evidence when Plastics Technology recently toured Bell’s company, The Rotuba Extruders Inc., Linden, N.J. What was abundantly clear was that he saw the LED lighting business shifting from acrylic and polycarbonate sheet to smaller customized profiles, and moved out of sheet to focus entirely on profiles as a result.

Earlier this year, Rotuba sold its sheet extrusion business to Plaskolite, Columbus, Ohio, freeing up manufacturing space at its 150,000 ft² New Jersey plant and adding additional profile extrusion capacity with new lines from Davis-Standard, Pawcatuck, Conn.

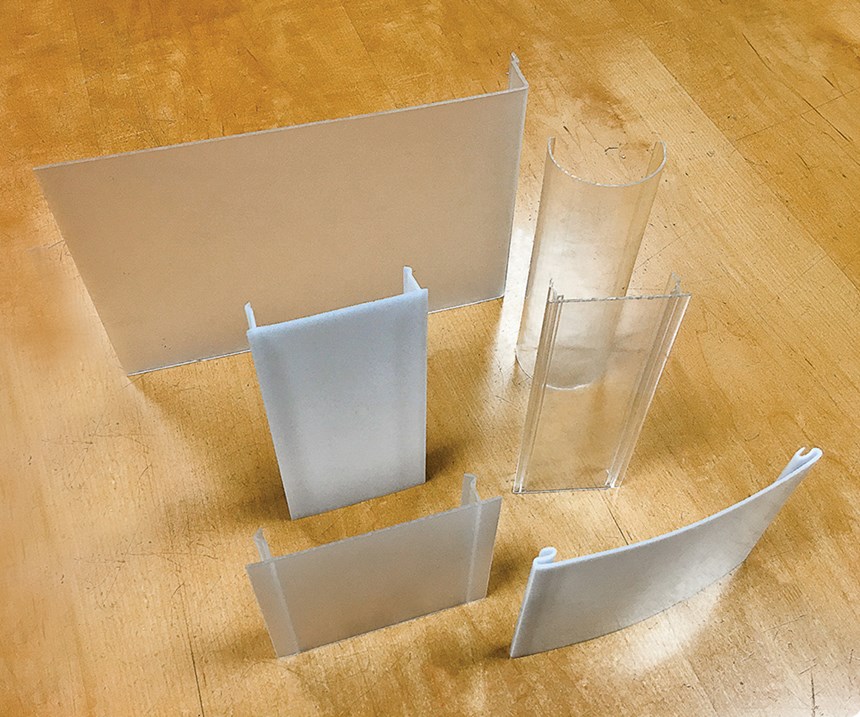

With this new focus, Rotuba can now produce more than 150 new custom profile designs annually for LEDs. Its various optical designs include microprisms, directional lenticular ribs, and custom designs to achieve optimal performance. Custom designs and material formulations often eliminate the need for overlays and secondary treatments, Bell explains.

Still, getting out of the sheet business was no easy decision, as Rotuba maintains it was the first company to extrude prismatic lighting sheets and profiles in PS and acrylic. But as Bell points out,

“With the growth of LED fixtures in the lighting industry, this deal allowed us to focus on growing the custom extruded profile segment of our business. The ability to design, build, and manufacture new extruded profile applications within days, in varying material formulations and polymers, is critical to our success in meeting the rapid changes in LED technology.”

Not that risk-taking is anything new for the Bell family, originally named Bielski. The 2008 movie Defiance was based on Nechama Tec’s 1993 book Defiance: The Bielski Partisans. The book told the story of a group led by Polish Jewish brothers—the Bielskis—who escaped Nazi-occupied Eastern Europe and fled into the Belarussian forests, where they joined Russian resistance fighters and built a village in order to protect themselves and about 1000 Jewish non-combatants.

Rotuba was founded in 1945 in Brooklyn by Bell’s grandfather, Walter Bell (Bielski), a brother of the WWII partisans, to make plastic rods, tubes, and bars. The firm moved to Linden in 1965. In 1973 Adam Bell’s father Albert assumed day-to-day responsibilities as president. Adam Bell himself started in sales for Rotuba in 1995 and took over as president and CEO in 2003.

Custom profiles are one leg of Rotuba’s three-legged business stool. In 1955, Rotuba started producing cellulose acetate (CA). Today, Rotuba is the largest independent custom compounder of CA in the world, running material from Eastman Innovation Lab, part of Eastman Chemical Co.., Kingsport, Tenn., for applications like screwdriver handles and eyeglass frames. It also is a custom-scent compounder of CA, cellulose acetate propionate (CAP) and cellulose acetate butyrate (CAB). In Linden, it has a twin-screw compounding line from Coperion Corp., Ramsey, N.J., dedicated to this product line. It’s equipped with state-of-the-art pelletizing equipment designed to eliminate dust and fines, which makes drying less problematic for its customers.

And a few miles from Linden in Garwood, N.J., the company has a wholly-owned subsidiary, Pen Company of America (formerly Rotary Pen), which it purchased in 2011. Pen Company injection molds components for pens and other writing instruments. Rotuba says Pen Company is the only company still manufacturing pens in the U.S.

VERTICALLY INTEGRATED

In Linden, the custom profile business operates about 250 days/yr on a 24-5 schedule. Rotuba has 18 extrusion lines, with two more on the way from Davis-Standard . Extruders range from 2 to 3.5 in. diam. Since 2005, the firm has been specifying extruders from Davis-Standard’s Super Blue line. These come standard with a low-noise, high-torque, double-reduction gearbox; cast-aluminum finned heaters bolted to the barrel; AC drive and motor; and a high-capacity air-cooling system. Rotuba has a mixture of downstream machinery from RDN Manufacturing Co., Inc., Bloomingdale Hills, Ill., and Conair, Cranberry Township, Pa. Most of its product runs are air cooled, though Rotuba also has water-cooling and vacuum sizing capabilities as well. Profiles are ordinarily cut to length. In some cases, offline steps such as additional cutting or notching are performed by operators.

Rotuba runs about 8 million lb/yr of PC, PS, and acrylic. Material is conveyed from gaylords and two outdoor silos. Drying is done either offline or at the machine. While Rotuba doesn’t focus much on color, it does plenty of work with other additives. Materials are highly tailored to the customer’s specifications by modifying the haze, light transmission, or diffusion of the lens. Rotuba’s primary sources of acrylic are Arkema Inc., King of Prussia, Pa., Evonik Corp, Parsippany, N.J., and Plaskolite, Columbus, Ohio. PC is sourced from several suppliers, notably SABIC, Houston. Rotuba worked with a supplier of blending equipment based in Israel to customize a system that combines the base resin with up to seven different additives to dose materials at levels as low as 0.250% of the total mixture. Bell says that Rotuba has about 20 different material formulations.

The company is moving to a paper-free production environment. Each extrusion line is equipped with an iPad mini that’s used as a “virtual set-up sheet,” says Bell. Rotuba also uses the tablet for production scheduling, monitoring, and tracking downtime.

Rotuba has three QC labs on the production floor, periodically pulling profiles from the lines to check for tolerances and other defects. Customer-specific requirements are considered for form, fit, color, light transmission, and function.

Rotuba can produce 2100 different designs. Some 85-90% of its tooling—including dies, sizing tools, and jigs and fixtures—are produced right in Linden in a tool shop that utilizes wire EDM, CNC, and lathes. Most recently, it installed a VF1 CNC machine from Haas Automation, Inc.., Oxnard, Calif. (haascnc.com), specifically to make intricate gauges for quality control.

A key to Rotuba’s success is being fast on its feet. Bell elaborates, “A project might start with a CAD drawing sent to us on Monday morning. That very same day we’ll have a conference call with the customer to discuss the design and the tolerances. At this point we exchange ideas on what could be changed, and why. That night we’ll start running a 3D model using our stereolithography (SLA) machine. By Tuesday the SLA model will be sent to the customer to see how it fits on their fixture. If they give us the approval on Wednesday, the project moves to the tool room and all the tooling will be cut. On Thursday we’ll be in a position to trial parts if the customer wants to fly in to see their part being run in up to five different LED formulations.”

In the LED lighting business, Bell believes that Rotuba’s level of vertical integration and its ability to turn computer drawings into finished parts quickly are crucial. “Those are among the things that set us apart,” he states. “But a major part of our success as a company is the commitment and energy of our team. Our people are committed to ‘going the extra mile.’ We also pride ourselves on making sure we are always communicating with our customers. And one of Rotuba’s objectives is to make sure we are always working on the next generation of products for each of our divisions, from the newest material for LED lighting to the newest additives for cellulosics.”

Bell adds, “Rotuba is uniquely positioned to offer our clients the latest engineered polymers to maximize LED performance. Our in-house facilities include 3D drawing, 3D printing, formulation creation, color matching, complete machining, and testing capabilities—providing fast and accurate new-product development.”

On the matter of speed to market, Bell states, “One of the reasons for our tremendous growth over the years is our ability to bring concepts to reality at lightning speed. Our engineers have access to state-of-the-art equipment in our lab and machine shop, allowing us the opportunity to develop new materials and designs for each of our product groups.”

Related Content

Troubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read MoreWhat to Know About Your Materials When Choosing a Feeder

Feeder performance is crucial to operating extrusion and compounding lines. And consistent, reliable feeding depends in large part on selecting a feeder compatible with the materials and additives you intend to process. Follow these tips to analyze your feeder requirements.

Read MoreMedical Tubing: Use Simulation to Troubleshoot, Optimize Processing & Dies

Extrusion simulations can be useful in anticipating issues and running “what-if” scenarios to size extruders and design dies for extrusion projects. It should be used at early stages of any project to avoid trial and error and remaking tooling.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read MoreRead Next

New Materials Shine Bright In Growing LED Market

Rapid expansion of LED technology has spurred development of new formulations for a wide range of lighting components. Here are examples of activity in this fast-moving field.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More