Radiation Crosslinking Boosts Nylon Properties

Demand for more robust plastics is creating new opportunities for radiation-crosslinked nylons, including nylon 6 and 66, which can serve as cost-effective alternatives to higher-cost, high-heat thermoplastics. Crosslinked nylons have higher heat resistance than their standard counterparts, along with better physical properties and abrasion resistance. Adapted from a paper presented at SPE ANTEC 2012.

Demand for more robust plastics is creating new opportunities for radiation-crosslinked nylons, including nylon 6 and 66, which can serve as cost-effective alternatives to higher-cost, high-heat thermoplastics. Crosslinked nylons have higher heat resistance than their standard counterparts, along with better physical properties and abrasion resistance.

It has been shown that a crosslinked nylon 6 compound can replace nylon 66, as crosslinking eliminates the need for the higher performance of the latter, while the nylon 6 also provides better low-temperature properties. This has been the case with a new family of radiation-crosslinkable, glass-reinforced nylon 6 compounds developed by Germany’s TechnoCompound GmbH for the North American market. Key to this offering is technical development support in cooperation with the electron-beam processor (in this case, E-BEAM Services) on the crosslinking step.

Radiation-crosslinkable nylons have been available for several years in Europe and in Japan and used for applications such as connectors, automotive parts (saving weight in high-heat areas), and military bushings. So far, they have had limited commercial application in North America, due in part to lack of local technical support.

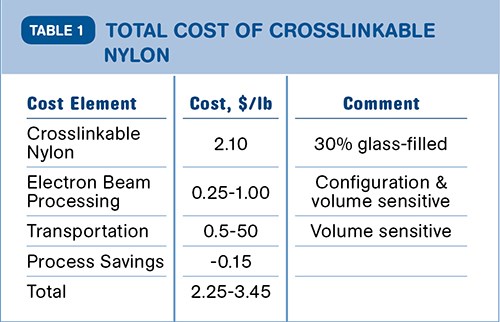

TechnoCompound offers nylon 6 compounds that can be crosslinked with standard electron-beam technology, including conveyor batch processing, in-line wire/cable processing, and film/sheet processing. Companies can utilize existing electron-beam processing equipment to replace higher-cost thermoplastics with high-performing and more economical crosslinkable nylon (see Table 1). TechnoCompound’s compounds have been targeted for electrical connectors, with a strong focus on automotive applications where higher temperature performance is required.

HOW IT WORKS

Nylons 6, 66, and 11 can be radiation crosslinked, but the first two require addition of a crosslinking agent. For example, the polyfunctional monomer triallyl isocyanurate or triallyl-cyanurate can be compounded into nylon pellets. The crosslinkable pellets can then be molded, extruded, or otherwise formed into the final product.

Compared with chemical crosslinking, the advantage to radiation crosslinking after forming the product is that mold and barrel temperatures can be run at the standard thermoplastic temperatures and the same cycle time can be expected. The crosslinking additive does not affect the thermoplastic processing stage.

After molding, the parts are radiation crosslinked to impart substantial improvements in properties. The molded parts or extruded cable or sheet are passed under the curtain of electrons that initiate free-radical formation. The crosslinking propagates via the crosslinking additive. Nylons typically require a dose between 60 and 120 kGy to reach a high level of crosslinking.

While gamma irradiation can also be used to crosslink nylon 6, there are some limitations. Gamma radiation delivers the crosslinking dose at a significantly lower rate than electron-beam processing. The additional processing time opens up opportunity for oxygen to enter the polymer structure, making the risk of oxidative degradation higher than with electron beam.

The key feature of these crosslinkable nylon 6 compounds is their ease of thermoplastic processing and the higher performance they offer after crosslinking: increased heat and chemical resistance, ESCR, and flame resistance.

LEAD-FREE SOLDERING SOLUTION

The European Restriction of Hazardous Substances Directive (RoHS) pertaining to electrical and electronic products is helping to drive a trend toward phasing out use of lead in soldering. Lead-free soldering involves higher heat exposure, which has led to the use of more expensive thermoplastics for high-heat connectors.

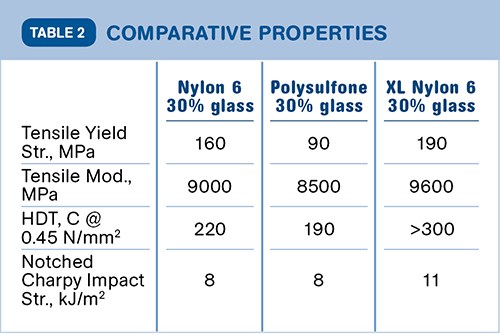

A low-cost solution is electron-beam crosslinked nylon connectors. See Table 2 for a comparison of properties of a crosslinked nylon 6 versus polysulfone and standard nylon 6 (all with 30% glass). The crosslinked nylon shows better properties than the uncrosslinked nylon 6 or polysulfone, especially in heat-deflection temperature, which was increased by greater than 75º C when the nylon 6 was crosslinked. Radiation-crosslinkable nylon 6 has been successfully used in automotive connectors that meet the increased temperature demand of the lead-free solder.

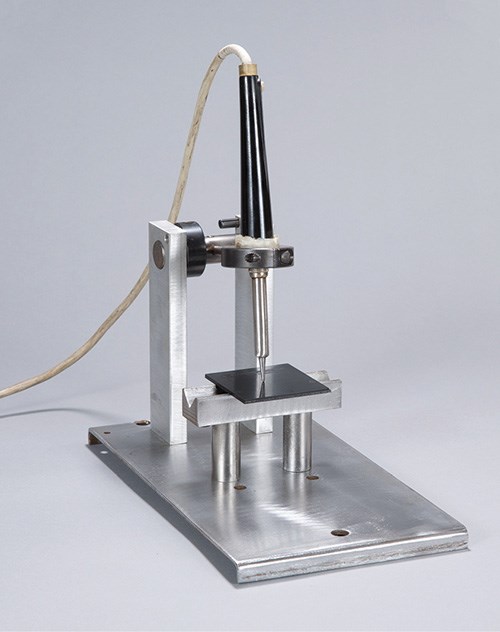

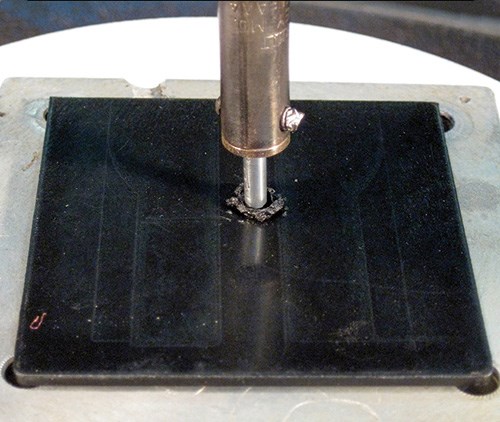

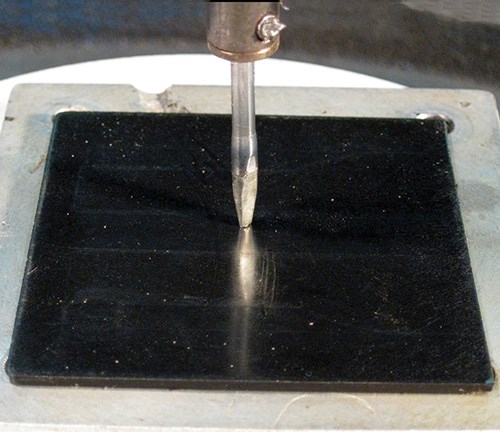

To measure the degree of crosslinking in a nylon, the gel content can be measured using an extraction method with m-cresol as the solvent. However, a simple test is often performed to determine a nylon’s crosslinking, called a “soldering iron test.” The accompanying photos show the experimental setup and the results with an unirradiated nylon 6 plaque and with a nylon 6 plaque that was irradiated to 80 kGy. The solder iron was heated to 350 C (662 F) and held in contact with the plaques for 30 sec. The load on the iron was 1000 g and the contact with the heat source was about 2 mm2. As is evident, the solder quickly penetrated the unirradiated sample but did not penetrate the radiation-crosslinked nylon plaque.

KEY DRIVERS FOR ADOPTION OF CROSSLINKED NYLONS

Companies that want to start replacing high-performance thermoplastics with crosslinkable nylon typically may need additional technical support. Since few processors have in-house electron-beam capacity, they usually need access to a contract e-beam processing facility. Such facilities are located across the U.S. and Canada, and there are now more than 10 such facilities that can support crosslinking of nylons.

Applications with high-heat and low-flammability requirements in both automotive and aerospace markets are a good fit for crosslinked nylon. Wire and cable products in the European automotive market often require electron crosslinking to pass a needle abrasion test that measures toughness. Crosslinked nylon jacketing has been shown to provide an outstanding combination of performance and cost. Many wire and cable users have been moving to global specifications that require radiation-crosslinked wire.

Other Activities in Crosslinked Nylon

Most of the development activity and commercial use of crosslinked nylons has taken place in Europe and Asia. Sumitomo Chemicals was among the first companies that pursued crosslinked nylons. By 2005, the company had developed new radiation-crosslinking nylon 66 molding compounds, which were adapted commercially for heat-resistant electrical connectors.

In late 2011, BASF (U.S. office in Florham Park, N.J.) and Sweden’s Nexam Chemical, a supplier of heat-activated crosslinkers for polymers, forged an exclusive cooperation agreement to develop and commercialize crosslinkable nylon 66 for automotive and electrical/electronic applications as initial targets.

Foster Corp., Dayville, Conn., developed its Fostalink crosslinkable elastomeric nylon compounds for medical applications such as catheters and valving, and nonmedical applications such as heat-shrink valving.

About the Authors

Bill Person is president of Wooddale Enterprises, Bloomfield Village, Mich. He supports North American sales and marketing of Germany’s TechnoCompound GmbH. He has over 25 years of experience in plastics. Contact: (248) 930-6284; email: wjperson20032003@yahoo.com.

Shannon Wayne is technical services engineer at E-BEAM Services, Inc., Lebanon, Ohio, a provider of contract electron-beam processing services at facilities in Ohio, New Jersey, and Indiana. Contact: (877) 413-2326; email: swayne@e-beamservicesohio.com.

Related Content

Tracing the History of Polymeric Materials, Part 26: High-Performance Thermoplastics

The majority of the polymers that today we rely on for outstanding performance — such as polysulfone, polyethersulfone, polyphenylsulfone and PPS — were introduced in the period between 1965 and 1985. Here’s how they entered your toolbox of engineering of materials.

Read MorePrices Up for All Volume Resins

First quarter was ending up with upward pricing, primarily due to higher feedstock costs and not supply/demand fundamentals.

Read MoreNPE2024 Materials: Spotlight on Sustainability with Performance

Across the show, sustainability ruled in new materials technology, from polyolefins and engineering resins to biobased materials.

Read MoreAutomotive Awards Highlight ‘Firsts,’ Emerging Technologies

Annual SPE event recognizes sustainability as a major theme.

Read MoreRead Next

See Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More