RECYCLING AT NPE: Three Es Starred

NPE2015 Wrap-Up

Recycling machinery suppliers focused on environmental, economical, and energy-saving.

March’s NPE2015 show in Orlando featured more news in recycling than perhaps any previous NPE. That’s not surprising: More and more OEMs, brand owners, and big-box retailers are demanding that plastics processors deliver them products containing recycled—in many cases post-consumer—materials. This, in turn, has driven innovations in equipment technology that aim to make recovery more efficient than ever. Here, we report on developments not already covered in previous issues.

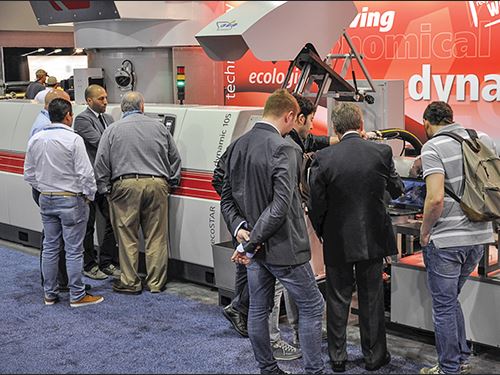

Starlinger (Starlinger Sahm in the U.S.) unveiled its recoSTAR dynamic recycling line, which features highly automated operation and continuous process adjustments. This allows increased uptime and productivity while also reducing overall energy consumption by up to 10%. The recycling line starts up and shuts down automatically; and when the material feeding is stopped, the Smart feeder switches into standby mode without operator intervention. Automatic temperature control allows processing of input materials with different moisture content and bulk density.

“This makes it possible to process, for example, post-consumer regrind or fluff that has varying moisture levels,” says Elfriede Hell, general manager of Starlinger. “Under unfavorable storage conditions, the moisture content in the input material can easily increase from 2% to 6%.”

The recycling line automatically adapts to the requirements of the input material and can even process material containing up to 10% moisture with the help of additional equipment. The speed and friction in the Smart feeder are increased until the required material temperature is reached. This can save the operator a lot of process adjustments and also cuts down machine downtime, Hell said.

In addition, the increased capacity of the large Smart feeder results in a much larger operating window, while the self-regulating material feeder allows the extruder to process a wider range of input materials. Additionally, upcycling is achieved by compounding during the recycling process. Additives can be fed directly into the extruder through a side feeder while the output feedback loop ensures total process control.

The recoSTAR dynamic will be the first of the Starlinger recycling lines to carry the “rECO” stamp. With this stamp, Starlinger is highlighting the comprehensive energy-efficient design of the new machine concept.

DRY CLEANING TECHNOLOGY

As reported in our March NPE preview, the Ekuma 700 super cleaner from MAS of Austria made its North American debut at the show. The unit reliably removes thermoplastic contamination from extrusion tools, filter parts, and more. No cleaning agents are required and contaminants are baked off under vacuum without any combustion. This protects the components against local overheating, annealing, and mechanical damage. A cleaning cycle takes 2 to 4 hr depending on part size, at a working temperature of 400-450 C. The unit can be installed in any room with a water supply and drain and an electrical power supply.

Using the phrase “washing without water,” MAS showcased its MAS DRD, a dry cleaning technology for plastic that is an alternative to conventional wet washing lines. The system combines a cleaning centrifuge with thermo-mechanical drying in one step. The double-disc rotor design allows for its use in a range of applications, such as a stand-alone drying and cleaning solution for plastic film and fibers or installation downstream of a wet cleaning plant to improve the quality of the washed flake.

WET GRINDER

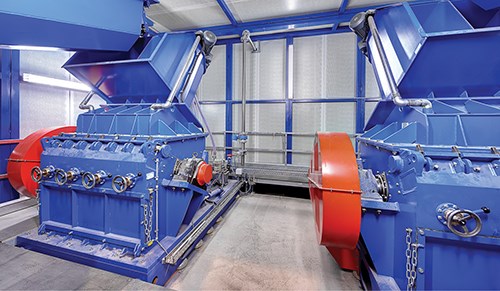

Zimmer America Recycling Solutions, North American agent for Germany’s STF Group, displayed STF’s new wet grinder at the show. The unit was developed for both dry and wet shredding of post-consumer plastics and is available in two sizes and with any screen hole size between 8 and 50 mm. By adding water, the shredding process provides a combination of grinding and cleaning. During shredding, around 95% of the paper labels are removed and dissolved in the water.

Also at the ZARS booth was Austrian Recycling Technology (Artec Machinery), which showcased its new Model 500 series recycling and extruder system for the first time in North America. The modular system can be adapted to various customer requirements. The six modules include: material feeder, cutter-compactor, extruder, degassing, filtration, and pelletizing.

NEW TANGENTIAL GRANULATORS

Zerma which recently expanded its operations and sales network to the North American market, introduced a new line of tangential granulators at NPE2015. The company presented its GST series of compact soundproofed granulators featuring a very “aggressive” tangential infeed and cutting chamber. These are available in two rotor diameters, 250 and 400 mm (10 and 16 in.) with widths ranging from 300 to 1000 mm (12 to 40 in.). While the smaller machines feature an open F type rotor, the bigger machines rely on a heavier S rotor. Replaceable wear plates are standard. The newly designed cutting chamber features a curved rear wall to ensure an aggressive ingestion while also avoiding blockages

Related Content

Inside the Florida Recycler Taking on NPE’s 100% Scrap Reuse Goal

Hundreds of tons of demonstration products will be created this week. Commercial Plastics Recycling is striving to recycle ALL of it.

Read MoreThe Importance of Mass Balance in Chemical Recycling

Approaches to mass balance can dramatically impact calculations of recycled content.

Read MoreNPE2024 Wrap-Up: Sustainability Dominates Show Floor News

Across all process types, sustainability was a big theme at NPE2024. But there was plenty to see in automation and artificial intelligence as well.

Read MoreMultilayer Solutions to Challenges in Blow Molding with PCR

For extrusion blow molders, challenges of price and availability of postconsumer recycled resins can be addressed with a variety of multilayer technologies, which also offer solutions to issues with color, processability, mechanical properties and chemical migration in PCR materials.

Read MoreRead Next

RECYCLING/SCRAP RECLAIM AT NPE: Less Waste And Lower Maintenance

Whether for commercial recycling or in-house scrap reclaim, new systems boast reduced maintenance, higher throughput, and less waste of resin for purging.

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More